vulcanic_5_1_2012_6_30

advertisement

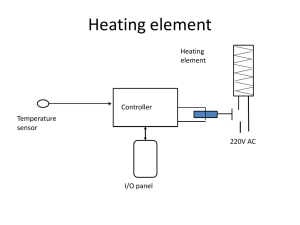

Electrical Heating and Cooling Solutions for the Industry EN-C2000 revO Key Figures 30 000 Customers in 100 countries 65 M€ Turnover 8 Plants 500 Employees A European Leader 2 Served Markets OEMs Engineering Projects One-off Requests 3 Our Offer… Heating of Solids and of static or circulating Fluids (Liquids, Air, Gas) • Heating Elements • Cartridge Heaters, Band Heaters, Strip Heaters, Heating Plates, PTC Resistors, Bolt Heaters, Silicone Heating Panels, Heating Tapes, Cables with mineral Insulation, … • Infrared Generators • Industrial Radiators, Finned Strip Heaters, Duct Heaters, Fan Heaters, Hot Air Generators, ... • Screw Plug Immersion Heaters, Ceramic Core Elements, Flexible Heating Hoses, Heating Belts, ... • Flange Immersion Heaters, In-line Flow Heaters, … 4 Our Offer Measurement and Temperature Control • Thermostats, Temperature Probes PT, Thermocouples, Transmitters • Displays, Measurement Converters, Communication Systems (Profibus, Device-net, Hart, Ethernet, Modbus, ...), PID controllers, ... • Power supplies, Power units, Cabinets with integrated control and power units,... Process Temperature Control Systems and Industrial Air Conditioning • Process Temperature Control Systems to achieve: heating, heating/cooling, heating/cooling with a frigorific unit, ... • Air Conditioners for Electrical Cabinets, Air/Water Heat Exchangers, Water Coolers, ... A unique global Offer 5 Engineering Projects Oil & Gas Main offshore & onshore applications: Oil Conditioning • Wellhead Crude oil heating for viscosity • Fuel oil forwarding for boiler/turbine • Suction line heating for storage tank • Waste Oil Heating Oil Fractioning and Polymerization - Gas Treatment • Continuous Catalyst Regeneration • Reactor catalyst beds temperature control . Hydrotreating . Hydrocraking • Isomerization • KO/Flare Drum Vapour/Liquid separator • Fuel gas conditioning for boiler start-up and gas turbines auxiliaries systems • TEG, MEG Dehydration • Natural gas heating to prevent from freezing before pressure reduction (compression and metering stations) • Liquefied natural gas heating and vaporizing • Gas Sweetening / Amine Gas treatment • Molecular Sieve Regeneration • Air/Gas separation processes 6 Engineering Projects Some customized Solutions • Onshore field oil heater 4 x ND 12“ • 420 kW / 230°C - 40 bar • PED 97/23/EC Cat IV • Design : ASME VIII div 1 • Offshore fuel gas heater • ND 24 “ - 1480 kW - 49 bar • ATEX Certification : II 3 G IIA T3 Heater : II 2 G Ex de IIC T3 Junction Box: II 2 G Ex e II T3 • Offshore Compression gas • Flange heater ND 700 pre-heater for large storage tank • ND 12 “ – 230 kW - 30 bar • 680 kW • ATEX Certification : II 2 G Ex e II T3 . 18-points individual flexible dual K-type thermocouple assembly for catalyst bed temperature measurement. . Design: 105 bar/ 445°C . ATEX certified II 2 G Ex d IIC T3 . 12-points individual flexible dual K-type thermocouple assembly for CCR unit . Wall-mount remote enclosure, Intrinsic safety Ex"ia" protection mode . ATEX certified II 1 G Ex ia IIC T3 - • H2/N2 heater ND 24“ • 680 kW / 450°C - 25 bar • Design : AD 2000 • Power panel 1100 A • 100% thyristors • Remote control cabinet Onshore LNG Vaporiser • Power and PID temperature • 4 x ND 8“ - 380 kW - 300°C control panel • Design : CODAP • 675 A/400 V 3 ph • PED 97/23/EC - Cat IV • 4 power stages • Self certified assembly : 7 • 100% thyristors II 3 G IIC T390°C Engineering Projects Oil & Gas Some Customers references: Engineering companies & Integrators AKER PROCESS SYSTEMS (Europe) AIR LIQUIDE (Europe + China) AIR PRODUCTS (Europe) ALFA LAVAL (Europe) AXENS (Europe) BHPV (India) CHINA FIRST HEAVY INDUSTRIES (China) DSME (Korea) EIED (Iran) ENGINEERS INDIA LIMITED (India) FOSTER WHEELER (Europe) GEA (Europe) GS E&CORPORATION (Korea) JAPAN STEEL WORKS (Japan) KBR (USA) KOBELCO (Japan) LARSEN & TOUBRO (India) LINDE (Europe) MESSER (Europe) SEI (China) LURGI (Europe) PROSERNAT (Europe) PUNJ LLOYD (India) SAIPEM (Europe) TECHNICAS REUNIDAS (Europe) TECHNIP (Europe + India) UHDE (Europe + India) PETROFAC (Russia) End Users ARAMCO (Saudi Arabia) AROMATICS OMAN (Sultanate of Oman) ARAK Petrochemical (Iran) BAYEROIL (Europe + Qatar) BP (Europe) CPCL/ INDIANOIL (India) ENOC PROCESSING (Dubai) EXXON MOBIL(Europe) HPCL MITTAL ENERGY (India) IFP (Europe) IOCL (India) NIOC (Iran) PETROBAS (Brazil) PETROCHINA /CNPC (China) PETRONAS (Malaysia) QAPCO (Qatar) SINOPEC ( China) GRT GAZ/ STORENGY (Europe) SHELL (Europe + Qatar) STATOIL (Europe) IRANIAN OFFSHORE (Iran) LUKOIL (Russia) PDVSA (Venezuela) SASOL (South Africa) TOTAL (Worldwide) 8 Engineering Projects Compatherm Heaters « High Load » heating rods • Material: SS 316L or INCONEL 600 • Load: 0,5 up to 80 W/cm2 • Available ATEX certification: Ex d IIC T1..T6 • PED 97/23/EC Compliance • ND 20 up to ND 600 • 1 up to 61 heating rods • Heating power up to 2500 kW • Low inertia • Compact • Reactive The solution for high pressure and high temperature applications An unique advanced technology 9 Engineering Projects Explosion protection types “ Ex d” Flameproof enclosures • Available sizes : ND 40 up to ND 700. • Material : painted aluminium, steel or stainless steel “Ex e” Increased safety enclosures • Available sizes : ND 100 up to ND 1000. • Material: painted steel or stainless steel. “Ex de” Flameproof & Increased safety enclosures • Available sizes : ND 40 up to ND 500. • Material: Cast iron, painted steel or stainless steel. Available temperature control devices • Thermocouples J or K type, RTD probes, Thermostats. • Temperature transmitters with Hart, Profibus PA, FieldBus communication protocols. • Ex d flameproof enclosures or Ex ia intrinsically safety protection. 10 Engineering Projects Vulcanic’s Expertise Design: • Thermal : with homemade softwares • Mechanical : • Calculation notes according to: - AD - Merkblatt. - ASME VIII div 1. - CODAP. - STOOMWEZEN. • 3D CAD (Solidworks). • Hydraulical. • Electrical. • Electronical: - Hardware. - Software. Certifications: • ISO 9001 v 2008 • 97/23/EC PED up to category IV • 94/9/EC ATEX • IECEx • GOST • VDE • UL • GL Dedicated • CCOE • Advise • Sizing • Project follow-up Tests: • Non destructive: liquid penetrant, X-ray, ultrasonic, Positive Material Identification... • Hydrostatic. • Helium leakage. • Electrical isolation and dielectrical rigidity in cold and/or hot conditions. • Harmonic and temperature rise of thyristors • Functional. Integrated Manufacturing: • Heating elements manufacturing. • Machining (drilling, turning, grinding) of mechanical components. • Printed circuit board assembling. • Mechanical and hydraulical assembling. • Welding . • Wiring. • Sheet metal working and painting. • Bench testing. Projects Teams: • Commissioning & Start-up assistance • Final documentation • After sales service Highly Integrated State-of-the-Art Industrial Means 11 A competitive Differentiation for YOUR Electrical Heating and Cooling Solution