Production Planning

advertisement

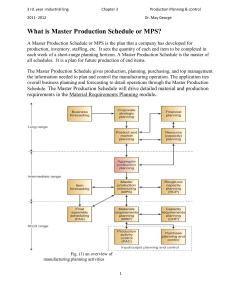

Production Planning Devaki Nadkarni Production Planning Decision Process Forecasts needed Corporate Allocates production among plants Annual demand by item and by region Plant manager Determines seasonal plan by product type Monthly demand for 15 months by product type Shop superintendent Determines monthly item production schedules Monthly demand for 5 months by item Decision Level Objectives of Production Planning • To deliver quality goods in required quantities to the customer in the required delivery schedule – to achieve maximum customer satisfaction and minimum possible cost. • To ensure maximum utilization of all resources. • To ensure production of quality products. • To minimize the product through-put time of production/manufacturing cycle time. • To maintain optimum inventory level. • To maintain flexibility in manufacturing operations. • To co-ordinate between labour and machines and various supporting departments. Production Planning Horizons Long-Range Capacity Planning Long-Range (years) Aggregate Planning Medium-Range (6-18 months) Master Production Scheduling Short-Range (weeks) Production Planning and Control Systems Very-Short-Range (hours - days) Pond Draining Push Pull Systems Systems (MRP) Systems (JIT) Focusing on Bottlenecks 4 Production Planning: Units of Measure Long-Range Capacity Planning Entire Product Line Aggregate Planning Product Family Master Production Scheduling Specific Product Model Production Planning and Control Systems Labor, Materials, Machines Pond Draining Systems Push Systems Pull Systems Focusing on Bottlenecks 5 Aggregate Planning Aggregate planning involves planning the best quantity to produce during time periods in the intermediaterange horizon (often 3 months to 18 months) and planning the lowest cost method of providing the adjustable capacity to accommodate production requirements. • It facilitates fully loaded facilities and minimizes overloading and under loading and keeps production cost low. • Adequate production capacity is provided to meet expected aggregate demand. • To manage change in production/ operations management by planning for production resources that adapt to the changes in customer demands. Flowchart of Aggregate plan and Master Production Schedule Market Environment Resource base and technology Forecast and customer order Capacity (facilities, material, labour and capital) Aggregate Production Plan Master Production Schedule Material Requirements Capacity Requirements Steps in Aggregate Capacity Planning • Prepare the sales forecast for each product that indicates the quantities to be sold in each time period. • Sum up the individual forecast into one aggregate demand. • Transform the aggregate demand for each time period into labour, materials, machines and other elements of production capacity required to satisfy aggregate demand. • Develop alternative resource schemes for supplying the necessary production to support the cumulative aggregate demand and choose the best that meets the objectives of the organisation. Master Production Scheduling The master production scheduling sets the quantity of each end item(finished product) to be completed in each time period of the short range planning horizon. Objectives: 1. To schedule end items to be completed promptly and when promised to customers. 2. To avoid overloading or under-loading the production facility so that production facility is efficiently utilized at the optimum cost. Functions of Master Production Schedule • Translating aggregate plans into specific end items. • Evaluating alternative schedules. • Generating material requirements. • Generating capacity requirements. • Facilitating information processing. • Maintaining valid priorities. • Utilizing capacity effectively. The elements of MPS: 1. Demand management. 2. Lot sizing. 3. No. of products to be scheduled(productmix). Symptoms of poorly designed MPS: 1. Overloaded facilities 2. Under-loaded facilities 3. Excessive inventory levels on some end items and frequent stock out on others. 4. Unrealistic schedules that production personnel do not follow. 5. Unreliable delivery promises to customers. 6. Excessive expediting or follow-up. Capacity Requirement Planning Capacity Requirement Planning is a techniques for determining what labour/personnel and equipment capacities are needed to meet the production objectives. It involves activities such as • Assessing existing capacity and forecasting future capacity needs • Identifying alternative ways to modify capacity • Evaluating financial, economical and technological capacity alternatives to avoid bottlenecks. • Plan capacity to achieve the production schedule Material Requirements Planning (MRP) Material Requirements Planning (MRP) is a system for planning the future requirements of dependent demand items. Material Requirements Planning Functions: • Order planning and control. • Priority planning and control. • Provision of a basis for planning capacity requirements and development of broad business plans. Successful implementation of MRP results into reduced levels of average inventory, optimum utilisation of human and capital resources, workforce planning, improved vendor relations, better capital investment decisions, reduced delivery lead times. Make or Buy Decision Considerations • Economic considerations. • Non economic considerations Availability of supply and alternative sources of supply for components and sub-units. Control of trade secrets and design secrets. Quality and reliability considerations. Delivery schedules to be met. Reliability of supply of external suppliers. Availability of manufacturing capacity (in-house) Independent vs. Dependent Demand Independent Demand Items Dependent Demand Items A C(2) B(4) D(2) E(1) D(3) F(2) Production Planning Hierarchy Firm orders from known customers Aggregate Product Plan Engineering design changes Master Production Schedule (MPS) Bill of Materials (BOM) file Material Requirements Planning (MRP) Reports Forecast of demand from random customers Inventory transactions Inventory records file Materials Requirements Planning (MRP) Materials Requirements Planning (MRP) • Computer based system • Explodes Master Schedule (MPS) into required amounts of raw materials and subassemblies to support MPS • Nets against current orders and inventories to develop production and purchased material ordering schedules Material Requirements Planning • How much of an item is needed? • When is an item needed to complete – – a specified number of units... in a specified period of time? • Dependent demand drives MRP Objectives of MRP • Improve customer service • Reduce inventory investment • Improve plant operating efficiency MRP Computer Program • Begins with number of end items needed • Add service parts not included in MPS • Explode MPS into gross requirements by consulting bill of materials file • Modify gross requirements to get net requirements: • Net Requirements = Gross Requirements + Allocated Inventory + Safety Stock - Inventory On Hand • Offset orders to allow for lead time Outputs of MRP • Planned order schedule - quantity of material to be ordered in each time period • Changes to planned orders - modifications to previous planned orders • Secondary outputs: – Exception reports – Performance reports – Planning reports More MRP Terminology • Gross Requirements –These requirements are typically forecast for independent demand items –Today’s trend is to replace forecasts with blanket orders in order to reduce variability and shorten lead-time –The customer is offered a price discount for placing blanket orders More MRP Terminology • On-hand inventory – The inventory physically present in the facility • Allocated inventory – The inventory physically present in the facility but allocated to a particular work order or purchase order More MRP Terminology • Net requirements –A quantity of an item that must be purchased or manufactured in order to be able to fully deliver independent demand requirements in a timely fashion –Presence of positive net requirements signals that an order must be planned to be received in a given period –Net requirement quantities are subject to adjustments due to lot sizes considerations. This may lead to some orders being received early (inventory is held) or late (order backlog) More MRP Terminology • Planned order released – Quantities that must be planned to be released in some future periods in order to meet the requirements More MRP Terminology • Scheduled receipts – Quantities that will be received in some future periods as their corresponding orders have been released in the past • Planned order receipts become scheduled receipts at the time when they are released to the shop or to suppliers More MRP Terminology • Gross to Net logic: Net Requirements = Gross Requirements + Allocated Inventory + Safety Stock - Inventory On Hand