Chapter 16

advertisement

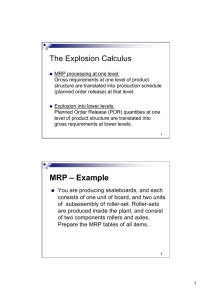

MRP Question: how do firms actually organize things to turn materials into finished products? Master Production Schedule (MPS) • Time-phased plan specifying how many and when the firm plans to build each end item Aggregate Plan (Product Groups) MPS (Specific End Items) MPS Example – Maine Woods Toy Co. One possible MPS… Product Month Week Tricycle Wagon Scooter Totals 41 300 300 October 42 43 44 45 300 300 300 300 300 300 300 2,400 300 November 46 47 300 300 300 300 2,400 48 49 300 250 250 300 December 50 51 250 250 250 250 2,000 52 250 250 Products are combinations of parts… Example: Bicycle Handle bars (1) Metal Frame (1) Wheels (2) Dependent vs Independent Demand • Independent Demand • Dependent Demand – Demand for an item is – Demand for a independent of the demand component (raw for other items. These material, part, subdemands are typically assembly) is dependent determined by outside on the demand for the customers and are end-item end-item into which the demands component goes. • demand often occurs in batches Bill of Materials (BOM) • Shows all the assemblies, subassemblies, components, and raw materials required to produce an item • Shows way a finished product or parent item is put together from individual components • Parent item shown at highest level or level zero • Parts that go into parent item are called level 1 components and so on • Production planners explode BOM for level zero item to determine the number, due dates, and order dates of subcomponents Let’s look at an example BOM... A Question: How many D’s we need in order to produce 50 A’s? B(2) D(3) C(1) E(3) D(1) Schematic of MRP System Material Requirements Planning (MRP) • Computer-based information system that schedules and orders dependent-demand inventory components; • Uses the master production schedule, bills of materials, and inventory records as inputs; • Outputs recommendations: – When to release new orders – When to reschedule open orders. Let’s look at an example BOM... A B(2) D(3) C(1) E(3) D(1) How do we manage order release? We need information on delivery times! Parts-Product A B C D E Process Lead Time 10 15 10 15 10 Let’s look at an example BOM... A (10) Question: B(2) (15) C(1) (10) When do we start producing/ordering each part? (15) D(3) E(3) (10) D(1) (15) Let’s assume that we need 50 units of A… Delivery date for final product 5 days Parts-Products A B C D E Let’s assume that we need 50 units of A… Start assembly for 50 units of A Parts-Products A B C D E Let’s assume that we need 50 units of A… Start assembly for 100 units of B Parts-Products A B C D E Let’s assume that we need 50 units of A… Start assembly for 50 units of C Parts-Products A B C D E Let’s assume that we need 50 units of A… Order 300 units of D for B’s process Parts-Products A B C D E Let’s assume that we need 50 units of A… Order 50 units of D for C’s assembly Parts-Products A B C D E Let’s assume that we need 50 units of A… Order 50 units of E for C’s assembly Parts-Products A B C D E Summary: How does MRP work? Material Requirements Planning Production Assembly Customer Production Assembly Production Units are PUSHED forward according to the plan! What about JIT/Lean Production? Production Assembly Production Customer Assembly Production Units are PULLED forward only when needed! Push/Pull Decoupling Point Material Requirements Planning Cheeseburger Hamburger Patties Forecast Hamburger Chicken Patties Chicken Sandwich Units are PUSHED forward to a certain point. Final configuration (PULL) occurs only when the actual customer demand occurs. Lot Sizing in MRP Systems • MRP generates material orders • Order sizes/lots can be chosen according to various objectives • Lot-for-lot (L4L): Produce to cover next period • EOQ: Apply the EOQ approximation for yearly demand • Least Unit Cost: Minimize total cost (order + carry) per unit These are all approximate methods, none is guaranteed to be optimal. We can apply all of them and find the least-cost one to implement. Example Cost per item: Order/setup cost: Inventory carrying cost/month Starting inventory: Production lead time Monthly requirements 1 2 3 4 5 100 50 80 120 70 $10 $47 2% 50 1 month 6 80 For the solution, see file mrp_methods.pdf MRP Evolution MRP Schedule Materials Closed Loop MRP Schedule Materials Incorporate Feedback MRP II Schedule & Purchase Materials Coordinate w/ Mfg Resources ERP Closed-Loop MRP Production Planning Master Production Scheduling Material Requirements Planning Capacity Requirements Planning No Realistic? Feedback Yes Execute: Capacity Plans Material Plans Feedback Manufacturing Resource Planning (MRP II) Goal: Plan and monitor all resources of a manufacturing firm (closed loop): manufacturing marketing finance engineering Simulate the manufacturing system ERP Systems Enterprise Resource Planning Systems is a computer system that integrates application programs in accounting, sales, manufacturing, and other functions in the firm This integration is accomplished through a database shared by all the application programs Typical ERP System Video: ERP at Hillerich & Bradsby Notes: Major ERP Providers Firm HQ Acquisitions 2004 Share of $23.6B Market SAP Germany Oracle US Sage Group UK 7% Microsoft US 3% Infor US 40% People Soft JD Edwards SSA Baan Source: AMR Research 22% Reasons to Implement ERP Desire to standardize and improve processes To improve the level of systems integration To improve information quality ERP Drawbacks Cost $250M+ for a Fortune 100 company Transition pain Implementation resources Training Resistance to change Summary and Conclusions… Master Production Schedule (MPS) converts aggregate plan to a detailed schedule Primary inputs to MRP are MPS, BOM’s (for part relationships) and Inventory Records (for lead times and inventory position) MRP is a push system but can be used in conjunction with pull systems MRP grew and evolved to include closedloop, Manufacturing Resource Planning (MRP II), and eventually ERP