ROLLING INDUSTRY - International Conference on Technology

advertisement

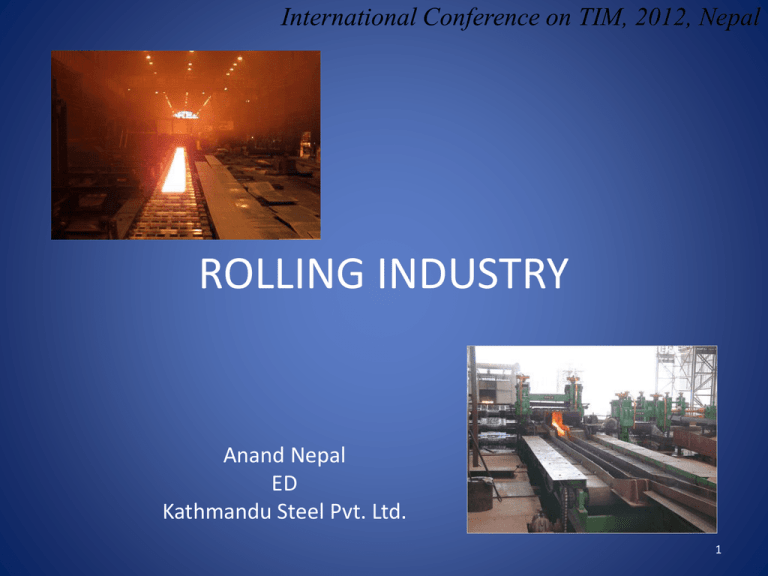

International Conference on TIM, 2012, Nepal ROLLING INDUSTRY Anand Nepal ED Kathmandu Steel Pvt. Ltd. 1 International Conference on TIM, 2012, Nepal Over View of Presentation • • • • • • Rolling Mills Process & Profiles Development & Innovations Nepalese Scenario Conclusion 2 International Conference on TIM, 2012, Nepal Rolling • Metal forming process in which metal stock is passed in between pair of rolls. – Hot Rolling : Temperature above re-crystallization – Cold Rolling : Temperature below re-crystallization 3 International Conference on TIM, 2012, Nepal Hot Rolling -Metal working process that occurs above the recrystallization temperature of the materials. -This prevent from work hardening. -Large piece of metal, Blooms, Billets, Slabs . -Continuous casting operation fed directly. -Must Heated, if room temperature materials. -Temperature should be monitored. -Form oxide at surface of metal during process. -Used to produce- sheet metal, simple cross sections 4 International Conference on TIM, 2012, Nepal Cold Rolling -Occurs with the metal below its re-crystallization temperature (room temperature). -Increase the strength. -Improve the surface finish and holds tighter tolerances. -Sheets, strips, bar, and rods: but they are smaller compared with hot rolled products. – sheets and strips different conditions- full hard, half hard, quarter hard and skin rolled. -Smaller size reduction as compared to hot rolled. -Require different operation: sizing, breakdown, semiroughing, semi finishing and finishing. 5 International Conference on TIM, 2012, Nepal Over View of Presentation • • • • • • Rolling Mills Process & Profiles Development & Innovations Nepalese Scenario Conclusion 6 International Conference on TIM, 2012, Nepal Mills -By Hot or Cold rolling and form or shaped in different products using machines. -Material are feed and output from mill is coiled or in different straight length. -Designed in different types of configurations: a)Two High, b)Three High, c)Four High, d)Six High and e & f) Cluster. (fig.) -Two high most basic & non reversing. -Three high rotate in one direction- fed through and returned back. Work piece to be lifted. 7 International Conference on TIM, 2012, Nepal -Minimize the roll diameter four high or cluster mill is used. -These mills (four high and cluster) requires lower energy and force . But the reduction of stiffness, which over come using backup rolls. These backup rolls are larger and contact the back side of the smaller rolls. -Four high mills has four rolls, Two small and Two large. -More than four rolls, known as cluster mill. Use for hot roll wide plates, most cold rolling applications and to roll foils. -Blooming and slabbing mills, being the preparatory mills to rolling finished rails, shapes or plates. -Mills classified by product produced: 8 International Conference on TIM, 2012, Nepal Mill-configurations 9 International Conference on TIM, 2012, Nepal -Billets mills- three high- rolls diameter 24-32 inch, preparatory mills for the bar and rod. -Beam mills-three high –rolls diameter 28-36 inch, preparatory for heavy beams and channels -Rail mills- 26-40 inch roll diameter. -Shape mills- 20-26 inch- smaller size beams and channels and other structures materials. -Merchant bar mill- 16-20 inch. -Small merchant bar mill- 8-16 inch. -Rod and wire mills- 8-12 inch. -Hoop and cotton tie mills, similar to smaller merchant bar mills. -Armour Plate mill- 44-50 inch -Plate mills- 28-44 inch -Sheet mills and Universal mill. 10 International Conference on TIM, 2012, Nepal Tandem Mill: The mill where rolling is done in one pass. Tandem mill there are several stands and reduction take place successively. Stand ranges from 2 to 18. Micro Mill: This is characterized by single strand continuous casting rolling process featuring ultra-high speed caster in line bar quenching & tempering and direct rolling bundling system organized in an extremely compact layout. 11 International Conference on TIM, 2012, Nepal Over View of Presentation • • • • • • Rolling Mills Process & Profiles Development & Innovations Nepalese Scenario Conclusion 12 International Conference on TIM, 2012, Nepal Process & Profile -Roll Bending: Producing cylindrical shaped product. -Roll forming: continuous bending operation in which a long strip of metal is passed through consecutive sets of rolls or stands each performing only an incremental part of bend, until the desired cross-section profile is obtained. -Flat rolling: Material fed in between two rolls, basic form of rolling with the starting and ending material having a rectangular cross-section. -Foil rolling: Specialized rolling, used to produce foil of sheet metal thickness less than 200µm (0.0079 in). 13 International Conference on TIM, 2012, Nepal -Ring rolling: It is specialized type of hot rolling that increases the diameter of a ring. The work-piece is placed between two rolls an idler roll, which another roll, called the driven roll, presses the ring from the outside. -Structural shape rolling: Cross-sections of continuously rolled structural shape, showing the change induced by each rolling mill. -Controlled rolling: It is type of thermo-mechanically processing which integrates controlled deformation and heat treating. In order to achieve the entire process must be closely monitored and controlled. 14 International Conference on TIM, 2012, Nepal Over View of Presentation • • • • • • Rolling Mills Process & Profiles Development & Innovations Nepalese Scenario Conclusion 15 International Conference on TIM, 2012, Nepal Development & Innovation -Earliest rolling mills were slitting mills, passed flat bars between rolls to form a plate of iron, introduced Belgium to England in 1590. -Early time, all work done manually. -1759 Thomas Blockley patent the polishing and rolling metals technology. -In 1766 first tandem mill patent to Richard ford of England. It was for hot rolling of wire. -Modern rolling practice started at end of eighteenth century 1783. -Developed by Henry Cort, using grooved rolls. 16 International Conference on TIM, 2012, Nepal -This mill produced 15 times more output per day compared to previous mills. -In 1820, first rail rolling mill was established. -Industrial revolution at end of eighteenth century and beginning of Nineteenth century brought revolution in rolling mill technology. -In 1850, 20 feet long, 3.5 feet wide, and 7/16 inch thick and 1,125 pounds weight plate was produced in England. -In 1853 three high mills introduces for heavy section rolling. -At end of Nineteenth century, more concentration on R & D. -Started automation and less hazardous conditions. -In 1964, mini/micro rolling mills. 17 International Conference on TIM, 2012, Nepal Over View of Presentation • • • • • • Rolling Mills Process & Profiles Development & Innovations Nepalese Scenario Conclusion 18 International Conference on TIM, 2012, Nepal Nepalese Scenario -Brought every materials from outside. -50 year back- a rolling mill started. -Technology compared was eighteenth century. It was tandem mill. -35 years back, another two/three mills started, technology is similar to first one. -Technology bought from India. -From today few year back, few rolling mill upgraded to more advanced mode of technology, which is nineteenth century technology. -There is no any micro/ mini mills . -Lack behind the technology and management. 19 International Conference on TIM, 2012, Nepal Conclusions - The quality, safety, management and time leads to new technology innovations at all time. 20 International Conference on TIM, 2012, Nepal THANK YOU 21