save-Rolling Mill - ROYAL MECHANICAL

advertisement

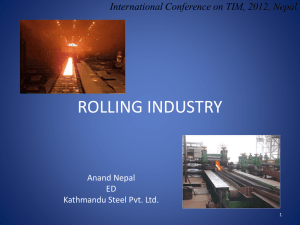

Rolling mill 1 Introduction to Rolling Rolling is a bulk deformation process in which the thickness of the work is reduced by compressive forces exerted by two opposing rolls. The rolls rotate to pull and simultaneously squeeze the work between them. Two High Rolling Mill 2 Introduction to Rolling The basic process shown in the previous figure is “Flat Rolling”, used to reduce the thickness of a rectangular cross section. A closely related process is “shape rolling”, in which a square cross section is formed into a shape such as an I-beam. Shape Rolling Flat Rolling Shape Rolling Two High Rolling Mill 3 Introduction to Rolling After casting, ingots are rolled into one of three intermediate shapes called blooms, billets, and slabs: Blooms have square cross section 6” x 6” or larger. They are rolled into structural shapes. Billets have square cross section 1.5” x 1.5” or larger. they are rolled into bars and rods. Slabs have rectangular cross section 10” x 1.5” or larger. They are rolled into plates, sheets and strips. Two High Rolling Mill 4 Introduction to Rolling •As any other metal forming process, rolling can be performed hot (hot rolling) or cold (cold rolling). •Most rolling is carried out by hot rolling, owing to the large amount of deformation required. •Hot-rolled metal is generally free of residual stresses, and has isotropic properties. On the other hand, it does not have close dimensional tolerances, and the surface has a characteristic oxide scale. Moreover, cold rolled metals are stronger. Two High Rolling Mill 5 Types of Rolling Based on work piece geometry : Flat rolling - used to reduce thickness of a rectangular cross section Shape rolling - square cross section is formed into a shape such as an I-beam Based on work temperature : Hot Rolling – most common due to the large amount of deformation required Cold rolling – produces finished sheet and plate stock Two High Rolling Mill 6 The Rolls Rotating rolls perform two main functions: •Pull the work into the gap between them by friction between work part and rolls. •Simultaneously squeeze the work to reduce its cross section. Two High Rolling Mill 7 Roll configurations in rolling mills Two High Rolling Mill. Two High Rolling Mill 8 Roll configurations in rolling mills Three High Rolling Mill. Two High Rolling Mill 9 Roll configurations in rolling mills Four High Rolling Mill. Two High Rolling Mill 10 Roll configurations in rolling mills Multiple backing rolls allow even smaller roll diameters Cluster Rolling Mill. Two High Rolling Mill 11 Roll configurations in rolling mills A series of rolling stands in sequence Tandem Rolling Mill. Two High Rolling Mill 12 Production steps in rolling Two High Rolling Mill 13 Change in grains structure in rolling Two High Rolling Mill 14 Rolling analysis • In flat rolling, the work is squeezed between two rolls so that its thickness is reduced by an amount called the draft: d = to - t f where d: draft to: starting thickness tf : final thickness As a fraction of the starting thickness: % reduction = % r = (d/ to) * 100% Two High Rolling Mill 15 Rolling analysis Rolling increases work width. This is called “spreading”. Spreading is expected because of the volume constancy in plastic deformation. Since the material is compressed in the thickness direction, both the length and width will increase provided that the material is not constrained in the width direction. Spreading is more pronounced with low widthto-thickness ratios and low coefficients of friction, since there is small resistance to flow in the width Two High Rolling Mill 16 direction. Rolling analysis The width-to-thickness ratio can be calculated as follows: w/t Ratio = initial width/ initial thickness After rolling, percentage spread can be calculated as follows: % Spread = (Final width-initial width)/ (initial width) *100% Two High Rolling Mill 17 Rolling analysis To calculate the roll force required to maintain separation between the two rolls: F = 1.15 * Yavg, i * Li * wi where: F : roll force Yavg, i : the average flow stress in the ith pass Li : the approximate contact length in the ith pass wi : the width of the sheet in the ith pass Two High Rolling Mill 18 Rolling analysis The torque in rolling can be estimated by: T = 0.5 * F * L Where: T: Torque (lb.in or N.m) F: Roll Force L: Contact length The Power required to drive the two rolls is calculated as follows: P = 2π*N*F*L Where: P: Power (in J/s =Watt or in-lb/min) N: Rolls rotational speed (RPM) F: Roll Force Two High Rolling Mill L: Contact length 19 Rolling Defects Defects in rolling may be either surface or structural defects: • Surface defects include scale and roll marks. • Structural defects (see next figure) include: 1. Wavy edges: bending of the rolls causes the sheet to be thinner at the edges, which tend to elongate more. Since the edges are restricted by the material at the center, they tend to wrinkle and form wavy edges. 2. Center and edge cracks: caused by low material ductility and barreling of the edges. 3. Alligatoring: results from inhomogeneous deformation or defects in the original cast ingots. • Other defects may includes residual stresses (in some casesTwo residual stresses are desirable). High Rolling Mill 20 Rolling Defects Structural defects in sheet rolling: Wavy Edges Center cracking Edge cracking Two High Rolling Mill Alligatoring 21 A rolling mill for hot flat rolling. The steel plate is seen as the glowing strip in lower left corner (photo courtesy of Bethlehem Steel). Two High Rolling Mill 22