Insert Title - IPEC

advertisement

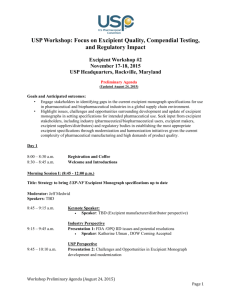

Atypical Actives PDA-FDA Conference March 9-10, 2011 David R. Schoneker Email: dschoneker@colorcon.com www.ipecamericas.org 1 What is an Atypical Active? • A chemical that is normally produced for use as an excipient, food additive or an industrial product that a customer decides to use (typically without the maker’s knowledge) as an API in a drug product (ie; OTCs… but not always!) • Usually NOT the maker’s intended market for the material so the manufacturing process and controls are NOT typically designed to meet API GMPs (ICH Q7) – Excipient or Food GMPs used www.ipecamericas.org 2 What is an Atypical Active? • Usually a very small market for the material compared to the normal uses • Typically, prices and margins are low compared to standard APIs • Seen by most suppliers as a liability risk with little business benefit www.ipecamericas.org 3 API (Q7) GMPs vs Excipient GMPs • Due to the nature of the manufacturing processes and distribution channels, it would be very difficult and costly to try to use API (Q7) GMPs when manufacturing Atypical Actives • The costs rarely would be justified from a business perspective due to the profit margins and market size www.ipecamericas.org 4 IPEC – Initial Concepts for Atypical Actives • GMPs aligned with the IPEC-PQG Excipient GMPs should be acceptable • Some additional technical considerations may need to be addressed; Examples: – Better understanding of specific composition and potential variability – Tighter specifications on critical properties where needed – Improved understanding of stability but not the same level of stability studies as required for standard APIs – Stronger change control and customer notification procedures • These are technical requirements, not a higher level of GMP www.ipecamericas.org 5 Atypical Actives Workshop Program • Overview of the Issue – Maker’s & User’s Perspectives • Regulatory Perspectives – FDA & EMA • Liability and Legal Issues • Impact on Users and Makers of Uncertainty • Case Studies – Real-Life Examples www.ipecamericas.org 6 Atypical Actives Workshop Program • Breakout Working Groups & Reports – Technical Considerations – what appropriate controls need to be considered for an excipient that is used as an API? – Regulatory Considerations – How can industry and regulators work together to resolve legislative and regulatory barriers to embrace a science and risk based approach? www.ipecamericas.org 7 Total Excipient Control (TEC) Tools for Managing Excipient Quality The Next Decade for IPEC www.ipecamericas.org 8 What is TEC and how to combine TEC Elements • IPEC’s first attempt at pulling together the various guidelines into an integrated structure was the development of the Excipient Qualification guideline • Provided overall guidance on how to use a number of the related IPEC guidelines to build a credible excipient qualification program from both the makers and the users perspective. www.ipecamericas.org 9 What is TEC and how to combine TEC Elements • As IPEC moves into our third decade we now want to take this concept even further and work towards the development of a system of Total Excipient Control (TEC) www.ipecamericas.org 10 What is TEC and how to combine TEC Elements • TEC will utilize all of the existing IPEC guidelines, programs and proposals to build an overall control system • TEC covers the controls needed from the time an excipient manufacturer thinks of marketing a chemical as an excipient to the pharmaceutical industry to the time the patient takes the drug product containing the excipient. www.ipecamericas.org 11 What is TEC and how to combine TEC Elements • We will determine where there may be gaps in our current toolkit and develop appropriate guidance or programs to establish Total Excipient Control. • IPEC’s challenge for the future!!! www.ipecamericas.org 12 The Building Blocks have been developed in the last 20 Years!! www.ipecamericas.org 13 TEC will finish things off and Add the Roof www.ipecamericas.org 14 The House that IPEC Built!! Patient Safety www.ipecamericas.org 15