Engineering solutions for independent eating

advertisement

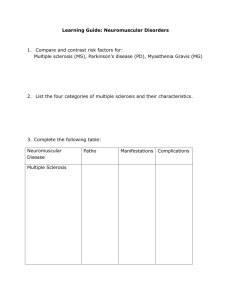

Accelerate Michigan Innovation Competition November 16-17, 2011 Jill Goryca Problem: Spilling soup while spoon is in transit to mouth Caused by shakiness from diseases such as Parkinson’s disease and multiple sclerosis. Opportunity: ◦ ◦ ◦ ◦ Stroke survivors: Nursing home residents: Parkinson’s disease: Multiple Sclerosis (MS): 4.7 million in US 1.5 million in US 500,000 in US 300,000 in US Separation Of Unsolid Portion Separates liquid from solid while spoon is in transit to mouth Allows the user to eat independently without making a mess. Novel technology with a strong intellectual property plan MS and Parkinson’s patients: 60,000/year Stroke survivors: over 500,000/year Elderly persons (65+): 40 million Nursing homes and assisted living centers (16,100 in US) FDA approval for Medicare/Medicaid reimbursement TV ads and retail sales in stores Disposable plastic samples ($1 ea.) in addition to stainless steel spoons ($25 ea.) Nursing Homes sales: 800,000 units is $20 million market opportunity. MS and Parkinson’s patients: 80,000 units for $2 million market opportunity. Disposable plastic spoons: 50 million units for a $50 million market opportunity. Size of market will increase by 20 million in the next 5 years as baby boomer population reaches retirement age. Windsford Feeder: Hands-free operation, but expensive and bulky solution Souper Spoon: Low cost, but spillage likely Low Cost Small Size Anti-spill Independence S.O.U.P. Spoon Windsford Feeder Souper Spoon Possible manufacturing alliances: ◦ Welch Allyn Medical Supplies ◦ Sur-Flo Plastics & Engineering, Inc. ◦ Linear Mold & Engineering Possible sales alliances: ◦ Binson's Home Health Care Supplies ◦ Advanced Medical Supply of Michigan Year 1: $80,000 ◦ Business start-up expenses, IP protection, part-time sales & marketing representative, initial production and testing, Gen 2 design and prototyping, packaging Year 2: $150,000 ◦ Manufacturing contract, marketing and sales, low rate production, warehousing, packaging, shipping and handling Year 3: positive cash flow ◦ Two full-time employees, marketing and sales, increase production, warehousing, packaging, shipping and handling Unit Sales Projections for First 3 Years Year 1 zero units Year 2 10,000 units Year 3 50,000 units Design Team: ◦ Jill Goryca, BSME: President & CEO ◦ Parker Farlow, BSME: Manufacturing ◦ Mike Rogers, BSME: Sales ◦ Mahdi Shoaeshargh, BSME: Financial Advisors: ◦ Delbert McCoy, Author of “Still on Fire” ◦ Dr. Molly McClelland, MSN, CMSRN, RN: Medical Advisor ◦ Dr. Darrell Kleinke, PE: Technical Advisor Superior product Inexpensive to manufacture Growing population of potential customers Great opportunity NHLB’s advantages over other teams: Passion Enthusiasm Desire to help people in need Receive funds from sponsor(s) for patent and manufacture of product. Build partnerships with start-up experts and manufacturing companies. ◦ Marketing ◦ Sales ◦ Intellectual Property