Poster

advertisement

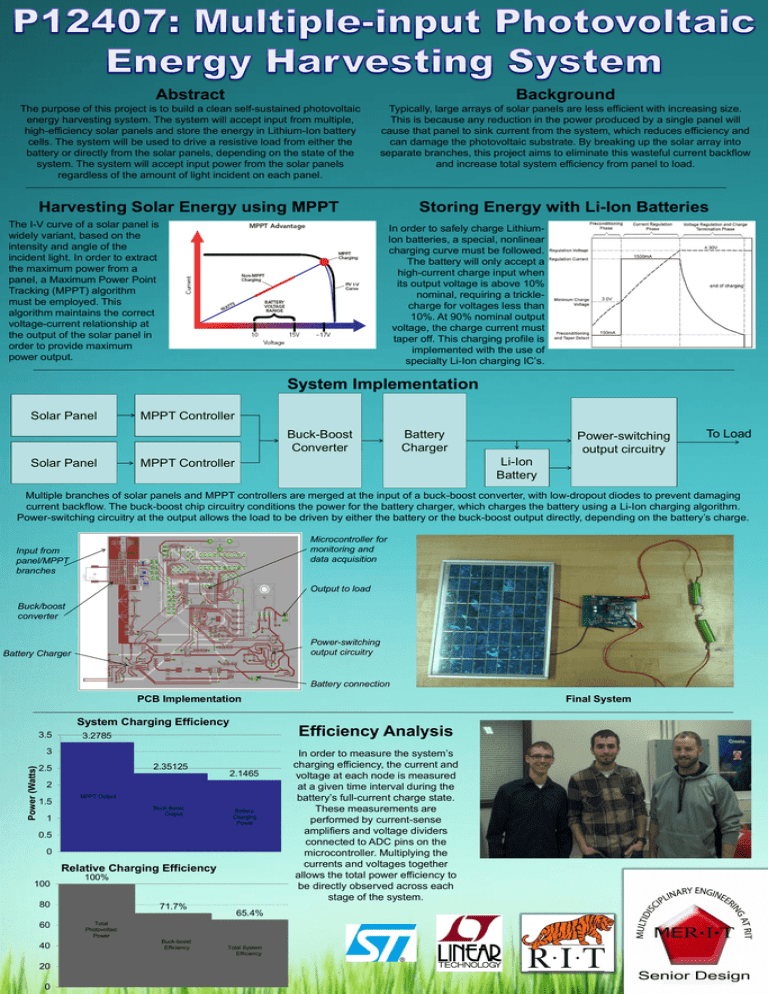

Abstract Background The purpose of this project is to build a clean self-sustained photovoltaic energy harvesting system. The system will accept input from multiple, high-efficiency solar panels and store the energy in Lithium-Ion battery cells. The system will be used to drive a resistive load from either the battery or directly from the solar panels, depending on the state of the system. The system will accept input power from the solar panels regardless of the amount of light incident on each panel. Typically, large arrays of solar panels are less efficient with increasing size. This is because any reduction in the power produced by a single panel will cause that panel to sink current from the system, which reduces efficiency and can damage the photovoltaic substrate. By breaking up the solar array into separate branches, this project aims to eliminate this wasteful current backflow and increase total system efficiency from panel to load. Harvesting Solar Energy using MPPT Storing Energy with Li-Ion Batteries The I-V curve of a solar panel is widely variant, based on the intensity and angle of the incident light. In order to extract the maximum power from a panel, a Maximum Power Point Tracking (MPPT) algorithm must be employed. This algorithm maintains the correct voltage-current relationship at the output of the solar panel in order to provide maximum power output. In order to safely charge LithiumIon batteries, a special, nonlinear charging curve must be followed. The battery will only accept a high-current charge input when its output voltage is above 10% nominal, requiring a tricklecharge for voltages less than 10%. At 90% nominal output voltage, the charge current must taper off. This charging profile is implemented with the use of specialty Li-Ion charging IC’s. System Implementation Solar Panel MPPT Controller Buck-Boost Converter Solar Panel Battery Charger Power-switching output circuitry To Load Li-Ion Battery MPPT Controller Multiple branches of solar panels and MPPT controllers are merged at the input of a buck-boost converter, with low-dropout diodes to prevent damaging current backflow. The buck-boost chip circuitry conditions the power for the battery charger, which charges the battery using a Li-Ion charging algorithm. Power-switching circuitry at the output allows the load to be driven by either the battery or the buck-boost output directly, depending on the battery’s charge. Microcontroller for monitoring and data acquisition Input from panel/MPPT branches Output to load Buck/boost converter Power-switching output circuitry Battery Charger Battery connection PCB Implementation System Charging Efficiency 3.5 Efficiency Analysis 3.2785 Power (Watts) 3 2.35125 2.5 2.1465 2 1.5 MPPT Output Buck-Boost Output 1 Battery Charging Power 0.5 0 Relative Charging Efficiency 100 100% 80 60 40 20 0 71.7% 65.4% Total Photovoltaic Power Buck-boost Efficiency Final System Total System Efficiency In order to measure the system’s charging efficiency, the current and voltage at each node is measured at a given time interval during the battery’s full-current charge state. These measurements are performed by current-sense amplifiers and voltage dividers connected to ADC pins on the microcontroller. Multiplying the currents and voltages together allows the total power efficiency to be directly observed across each stage of the system.