Systems Design Review Packet

advertisement

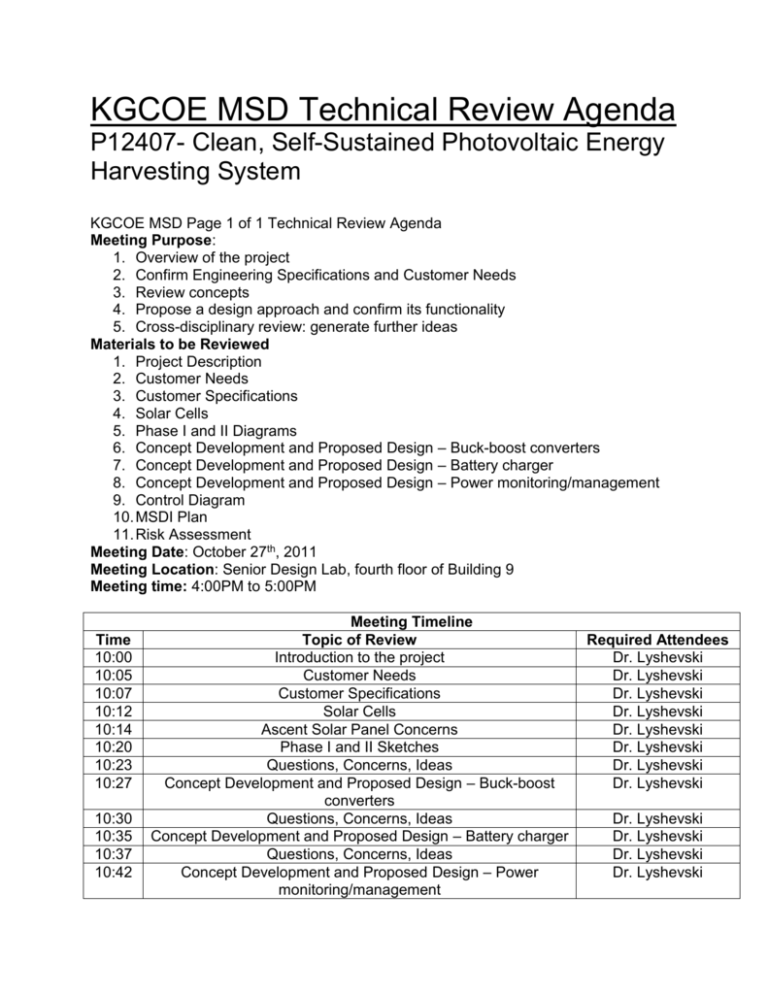

KGCOE MSD Technical Review Agenda P12407- Clean, Self-Sustained Photovoltaic Energy Harvesting System KGCOE MSD Page 1 of 1 Technical Review Agenda Meeting Purpose: 1. Overview of the project 2. Confirm Engineering Specifications and Customer Needs 3. Review concepts 4. Propose a design approach and confirm its functionality 5. Cross-disciplinary review: generate further ideas Materials to be Reviewed 1. Project Description 2. Customer Needs 3. Customer Specifications 4. Solar Cells 5. Phase I and II Diagrams 6. Concept Development and Proposed Design – Buck-boost converters 7. Concept Development and Proposed Design – Battery charger 8. Concept Development and Proposed Design – Power monitoring/management 9. Control Diagram 10. MSDI Plan 11. Risk Assessment Meeting Date: October 27th, 2011 Meeting Location: Senior Design Lab, fourth floor of Building 9 Meeting time: 4:00PM to 5:00PM Time 10:00 10:05 10:07 10:12 10:14 10:20 10:23 10:27 10:30 10:35 10:37 10:42 Meeting Timeline Topic of Review Introduction to the project Customer Needs Customer Specifications Solar Cells Ascent Solar Panel Concerns Phase I and II Sketches Questions, Concerns, Ideas Concept Development and Proposed Design – Buck-boost converters Questions, Concerns, Ideas Concept Development and Proposed Design – Battery charger Questions, Concerns, Ideas Concept Development and Proposed Design – Power monitoring/management Required Attendees Dr. Lyshevski Dr. Lyshevski Dr. Lyshevski Dr. Lyshevski Dr. Lyshevski Dr. Lyshevski Dr. Lyshevski Dr. Lyshevski Dr. Lyshevski Dr. Lyshevski Dr. Lyshevski Dr. Lyshevski 10:43 10:45 10:48 10:50 10:55 11:00 Control Diagram Questions, Concerns, Ideas Project Plan Questions, Concerns, Ideas Risk Assessment Questions, Concerns, Ideas Dr. Lyshevski Dr. Lyshevski Dr. Lyshevski Dr. Lyshevski Dr. Lyshevski Dr. Lyshevski Project Description Expected Project Benefits: Project Background: Produce a clean, self-sustained photovoltaic energy harvesting system from multiple input power sources. A clean, self-sustained photovoltaic energy harvesting system is the focus of this project. Photovoltaics will be used to acquire the energy from light and this energy will then be sent through an energy management system to charge a battery or drive a load. Core Team Members: Mike Grolling- EE- Energy Storage Josh Stephenson-EE- Power Conditioning Tom Praderio-EE- Power Management Problem Statement: Properly manage energy from multiple sources to charge a battery and drive a load. The team shall establish and then guarantee efficiency parameters based on benchmark results. This will require the team to investigate various applied technologies, components, and modules to establish engineering specifications. System and individual module efficiencies shall approach that of benchmarked modules where feasible. Objectives/ Scope: 1. 2. 3. 4. 5. 6. Generate (average) ~5 W of energy (rated). Highly efficient photonic-to-electrical, electrical-to-electrical and electrical-tophotonic energy conversions. Superior light harvesting capabilities. Sufficient energy storage abilities. Robust voltage stabilization and distribution. Energy management system with multiple photovoltaic energy source types. Deliverables: Highly efficient energy conversion that meets customer needs A functioning portable prototype Assumptions and Constraints: The team must obtain a well-rounded understanding of energy management and harvesting. By using multiple inputs which have different loading capabilities, a system must be in place to isolate low voltage photovoltaics. Issues & Risks: Improper battery voltage regulation may lead to permanent battery damage, swelling, or explosions Oversized solar cells may lead to excessive heat dissipation through the parts and result in shortened lifetimes or failure Customer Needs Customer Need # Importance CN1 CN2 1 1 CN3 CN4 CN5 1 1 1 CN6 CN7 CN8 CN9 CN10 CN11 CN12 1 1 1 1 1 1 1 Description Design will include safety and component failure Ability to manage inputs from multiple power sources Investigate and benchmark technologies, components and modules Engineer multiple concepts. Perform tradeoff analysis System will integrate power management and load distribution. Establish highly efficient energy conversion parameters and design System must manage energy source variability Provide data acquisition points for future team's display design System must be portable System must include instructions for set-up and use System must utilize Ascent Solar’s flexible solar modules Adequate amount of energy storage Comments/Status Example: Li-ion Batteries (place in a wooden box when testing) 3-5 solar panel inputs/ do not load low voltage panels Find efficient battery charging technology Efficiency is dependent on light conditions Example: clouds or night-time Data acquisition is performed by the microcontroller Ascent Solar competition requirement Ascent Solar competition requirement Ascent Solar competition requirement Project Specifications Spec. # Importance Source Function Specification (metric) S1 1 Power S2 S3 1 1 CN11 CN3,4,5, 7,8 CN5,7 V Stability V out S4 S5 S6 1 1 1 CN7 CN1, 7 CN12 I out I out Storage S7 1 Ability to generate ~5W of energy Voltage stabilization for battery charging (~15V ±0.05V) Output voltage to load of 10V Full solar delivery, provide a max output current of 0.5A Peak output current will meet 5A max Battery capacity is ~5 A-h Power load to simulate future display device at a constant 5W Load/Display S8 CN2 Input S9 S10 CN3 CN4 All All S11 S12 S13 S14 S15 CN6 CN8 CN9 CN10 CN6 All All Unit of Measure Marginal Value W V V A A A-h 14.95V15.05V N/A N/A W Multiple solar panels Benchmark given component's specifications Weigh concepts for each function Calculate, design, measure each function List DAQ points V/A User's manual Efficiencies for each function N/A Ideal Value Comments/Status 5 Average power 15 10 Needs clarification 0.5 5 5 Choose an appropriate battery 5 5V-36V / 0A-1A Efficiencies N/A N/A Proposed Solution Diagrams Phase 1 0V to 36V 10V 15V Buck-Boost Converter Photovoltaic Panel 10V Battery Charger Load Battery SPI Bus Interface Switch ON/OFF control line Microcontroller Voltage and current sensing circuitry Figure 1: Single-source testing concept model 0V to 36V Photovoltaic Panel Buck-Boost Converter Phase 2 10V 15V Photovoltaic Panel Buck-Boost Converter 10V Battery Charger Load Battery Photovoltaic Panel Buck-Boost Converter Charging current monitor SPI Bus interface Microcontroller Voltage and current sensing circuitry Switch ON/OFF control lines Figure 2: Multiple-source concept model Selection Criteria Max charge current Adjustable output Number of cells supported Efficiency Load bypass Overall Rank Rating + 0 + + Concept Selection - Battery charger LTM4006 LM3420 Notes Rating Notes 4A 20mA Preset values No 4 0 4 96% 0 Yes No 1 3 Rating + + 0 + - ADP3806 Notes 3A Yes 95% No 2 Table 1: Battery charging concept selection Selection Criteria Input voltage range Output voltage range Quiescent current Efficiency at 250mA Output disconnect Overall Rank Rating + + Concept Selection - Buck Boost Converters LTM4607 ADP1111 Notes Rating Notes 4.5V-36V + 2V-30V 0.8-24V + 3V-Vin 300uA 85% (12V) Yes 0 No 1 2 Rating 0 + + 0 SM74301 Notes 6V-95V 2.5V-Vin 92% (15V) No 3 Table 2: Buck-boost converter concept selection Selection Criteria Voltage sense maximum Sensor channels per chip Power consumption System complexity Overall Rank Rating + 0 - Concept Selection - Power Management SM72441 Microconroller ADC (voltage division) Notes Rating Notes 0 to DC supply + Depends on division resistors 8 + 24 50mW + on the order of uW Complicated 0 Passive components needed 2 1 Table 3: Power Management concept selection Rating 0 0 - ADM1276 Notes 2V to 20V 1 One chip needed per sense line 3 Figure 3: Buck Boost Converter Application diagram Figure 4: Battery Charger Application diagram NC NC Note: Thermistors used as a precautionary measure against battery overheating Figure 5: Microcontroller application diagram 3V Battery Vcc1 From BBC Output Voltage Divider ADC1 GPIO From BBC Output Current Sense Amp ADC2 From Charger Current Monitor ADC3 MSP430F6638 Microcontroller SPI_MISO From Load Output Voltage Divider ADC4 SPI_MOSI From Load Output Current Sense Amp ADC5 SPI_CLK ADC6 SPI_SS ADC7 UART_TX To PV Disconnect Switch GPIO ADC8 From BBC SPI Data Out To BBC SPI Data In To BBC SPI Clock To BBC SPI XCO RS232 Level Shifter To PC via RS232 UART_RX GND Note: All BBC lines will be duplicated for each buck-boost converter in the final design. The MSP430 will support up to eight BBC’s. Data Acquisition Points Output of each photovoltaic panel o Voltage and current are measured internally by each buck-boost converter o Data is reported to the microcontroller via an SPI serial bus Output of each buck-boost converter o Current is measured by a LTC6102 current sense amplifier o Voltage is measured by a high-impedance simple voltage divider o Data is reported to the microcontroller via an ADC channel Battery charger output o Measured internally by the battery charger o Data is reported to the microcontroller via an ADC channel System output/load o Current is measured by a LTC6102 current sense amplifier o Voltage is measured by a high-impedance simple voltage divider o Data is reported to the microcontroller via an ADC channel Figure 6: Microcontroller software algorithm for photovoltaic power management Figure 7: Current Sensing solution application diagram Action Item Learn PCB Express System Design Review Order Samples TI Competition App Choose devices Design Passive Comp Cadence Schematic Psuedo Coding BOM Detailed Review Update BOM Order Parts Contact Ascent Solar Test Samples Week 8 Week 9 Week 10 Week 11 Fall Break Severity Importance Table 4: Senior Design I Time Line Risk Assessment ID 1 Risk Item Effect Cause Team runs out of time Project doesn't get finished Poor project planning Likelihood 2 5 Action to Minimize Risk Follow timeline and 10 manage weekly updates 2 Parts arrive late Schedule is delayed Unreliable vendor 2 3 Constant 6 communication with Vendor Prototype draws too 3 much power or is inefficient Photovoltaics produce 4 insuffient/minimum power Poor battery life/does not meet customer spec Poor choice of technology 1 3 3 Choose low power/high efficiency electronics Very low efficiency and power generation Poor pairing of solar cells with DC/DC Conv. 2 5 9 Examine energy curves for different solar cells Buck Boost converter incapable of blocking 5 reverse bias conditions reverse currents will drastically lower efficiency and may compromise operation or damage solar cells Poor isolation of energy sources 7 Place diode across each 8 solar cell to dissipate reverse emf Internal electronics produce too much 6 heat/ambient temp too high Electronics overheat; inefficient Poor choice of electronics or casing; unrealistic goals 2 2 Choose low power 4 electronics with wide operating temp range Internal electronics 7 do not produce acceptable signals Redesign/ project goals not met Low margins of safety/ high-risk technology 2 3 6 Work with electronics that are acceptable 1 8 Requirements change during the project Project will not be able to change in time Redesign required 1 5 5 Verify deliverables with customer 9 Teammates do not do assigned work Team will need to do the work for the teammate Laziness/ not enough time 1 3 6 Ask for help with needed Team will be delayed and work will be postponed Laziness/ not enough time 2 Assign tasks that have a 4 high likelihood of being completed Teammates do not 10 arrive prepared 2 Inability to contact 11 the customer or guide May miss vital information and requirements Poor Communication 2 2 Keep constant info flow 4 with the customer and guide Getting wrong 12 information from customer Lead to solving an issue that doesn't exist Poor Communication 2 3 6 Set up meeting s and communicate often Arguments between 13 teammates Will hurt team morale and cause conflict between members Poor Communication 2 2 4 Have group focused and group leader aware Microcontroller not 14 fast enough to manage power Power management will be ineffective Poor part selection 2 2 Microcontroller 5 selected with appropriate speed Microcontroller code 15 does execute properly Power management will be ineffective Poor coding 4 7 8 Code will be thoroughly tested and debugged