Business Plan: 3D Additive Manufacturing Technologies, Co. * 3

advertisement

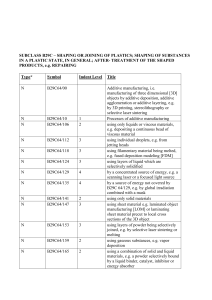

BUSINESS PLAN: 3D ADDITIVE MANUFACTURING TECHNOLOGIES, CO. – 3-DAMTM Starting A New Venture – MGMT 6630 Joe Ott 7-18-2012 BUSINESS CONCEPT • 1. INTRODUCTION • • • • • 2. THE COMPANY • • 2.1. LEGAL STRUCTURE AND OWNERSHIP 3. PRODUCTS / SERVICES • • • • • 1.2. BUSINESS IDEA 1.3. BUSINESS MODEL 1.4. BUSINESS GOALS 1.5. KEYS TO SUCCESS 3.1. PRODUCT AND SERVICE SUMMARY 3.2. CUSTOMER 3.3. TECHNOLOGY 3.4. REGULATORY ISSUES 4. THE MARKET • • • 4.1. MARKET ANALYSIS 4.2. TARGET MARKET SEGMENT 4.3. GROWTH POTENTIAL • 5. THE INDUSTRY • 6. SALES • • • • • • • • • • 5.1. COMPETITION 6.1. SALES STRATEGY. 6.2. PRICE STRATEGY 6.3. PROMOTION STRATEGY 6.4. SALES FORECAST 7. THE MARKETING PLAN 8. MANAGEMENT AND EMPLOYEES 9. ACTIVITY PLAN 10. FINANCE AND ECONOMY FIGURES BACK UP SLIDES 1. INTRODUCTION - “With 3-DAMTM comes manufacturing freedom!!” • 1.2. BUSINESS IDEA • The business idea behind 3-DAMTM is to cross additive manufacturing technology with the “KinkosTM” concept. • Customers contact store by appearance, email, web submission • Business would staff trained engineers and technicians to assist customers in selecting the correct technology to manufacture their hardware. • 1.3. BUSINESS MODEL • Sole Proprietorship during the initial start-up phase • Would initially target a small volume of jobs, applying a medium margin. • Diversification Growth Strategy - 3-DAMTM would practice Forward Integration by getting in front of the customer 1. INTRODUCTION - “With 3-DAMTM comes manufacturing freedom!!” • From ASTM Designation: F2792 – 10 - Standard Terminology for Additive Manufacturing Technologies2 • Why pursue additive manufacturing? There are many benefits in using additive manufacturing to make hardware over conventional manufacturing5: • • • • • • • • • • • • • • Design flexibility No tooling constraints Allows complex models No hard tooling required No material lead time Automated process Reduced development expenses Faster concept design to functional component Reduced manufacturing costs Near wrought material properties Reduced product life cycle cost Reduced manufacturing time: hours/days/weeks vs. months Minimal secondary machining - near-net shape part Additive manufacturing is an emerging industry. • Some of the difficulties with additive manufacturing are: • New technology – not everyone is familiar, technology evolving • High barriers to entry – initial high start-up costs for equipment • Material properties are still being defined • Technical and process models are limited Picture courtesy of Rapid Quality Manufacturing5 1. INTRODUCTION - “With 3-DAMTM comes manufacturing freedom!!” • 1.4. BUSINESS GOALS • 2 years of operation: • Increase market share – establish 4 stores in largest US manufacturing locations (Houston, TX; Milwaukee, WI; Seattle, WA; San Antonio, TX)4 • Increase market penetration over time –grow each store’s revenue at least 12.5% yearly • Establish new pricing incentives and promotions • Build long lasting quality partnerships • Advertising • Join Committee F42 on Additive Manufacturing Technologies1 • 6 years of operation: • Increase market share – establish a store in 10 major US cities. Have plan developed to have 50 stores in major US cities by 10 years of operations. • Increase market penetration over time – continue to grow revenue at least 12.5% yearly, per store. • 1.5. KEYS TO SUCCESS • Flexibility – providing solutions for variety of customer and their unique requirements. • Adaptability – have technology and capability for variety of needs. • Sustained Growth – have capacity where and when a customer needs it. • Technical “Know-how” – have understanding of how to use additive manufacturing technology to provide best results. • Speed – providing solutions faster and more efficient than anyone else. • Funding – have cash and capital to sustain growth and profit. 2. THE COMPANY - “With 3-DAMTM comes manufacturing freedom!!” • 2.1. LEGAL STRUCTURE AND OWNERSHIP • 3-DAMTM will be listed with the Internal Revenue Service as a sole proprietorship • The principle owner (and equity shareholder) will be Joe Ott. • Minor equity shareholders (<49%) will be silent partners Figure 1. – Basic Organizational Structure 3. PRODUCTS / SERVICES - “With 3-DAMTM comes manufacturing freedom!!” • 3.1. PRODUCT AND SERVICE SUMMARY • Plastic and metal parts and concepts, produced in a few hours or days, using additive manufacturing technologies • Evaluation and modification of designs/CAD and concepts for application to additive mfg. • Coordination of post processing. • Metrology center – accurate measurement evaluation • 3.2. CUSTOMERS • The target customers are everyone from local hobbyist and enthusiast to large Fortune 500 companies needing unique part developed and produced. • The current market doesn’t have local “to-go-to” places to get all your materials and additive manufacturing methods and post-processing under one roof. • All competition is located in a few select areas • 3-DAMTM would provide a place for customers to have one-stop-shopping for their manufacturing. Customer(s) can contact the business center by phone, web, or face-to-face. Sales engineers would be available to help customers work through product development and iteration until the final product is ready. Pricing would be evaluated based upon the necessary amount of engineering and development to make hardware, material considerations, and post processing requirements. 3. PRODUCTS / SERVICES - “With 3-DAMTM comes manufacturing freedom!!” • 3.3. TECHNOLOGY • • • • • • • • Powder Bed Technologies - Powder Bed is the distribution of thin layer of powder (metal or thermoplastic) and uses an energy source to sinter/melt the powder into solid form. Powder Bed Technologies offer high resolution, medium volume, small to medium sized part capabilities. Two common methods are: Selective Laser Melting – laser beam power source in an inert atmosphere (nitrogen or argon) Electron Beam Melting – electron beam power source in a heated, vacuum environment Deposition Technologies – Metal is introduced via powder nozzle or wire feed into an energy source directly at the build location, which melts to metal into solid form. Deposition Technologies offer lower resolution, lower volume, larger sized part capabilities. 3 common methods are: Laser Powder Deposition – laser/power nozzle combination Laser Wire Deposition – use of a continuous feed wire and laser energy source Electron Beam Wire Deposition – use of continuous feed wire and EB energy source Specialized Software – (CAD/CAM, 3D model analysis, project/customer management) will be required to seamlessly integrate customer models between additive mfg. platforms and required post processing technologies. • 3.4. REGULATORY ISSUES • • • • • "Green Technology" PPE Inert Gases Intellectual Property7 Product Liability7 Pictures courtesy of EOS (http://www.eos.info/en/home.html), Arcam (http://www.arcam.com/), and Optomec (http://www.optomec.com/) 4. THE MARKET- “With 3-DAMTM comes manufacturing freedom!!” • 4.1. MARKET ANALYSIS • • • Wohlers Associates Inc. - Additive manufacturing had a total of market size of $1.7 billion worldwide in 2011. Emerging Industry - Additive manufacturing can be considered an emerging industry in the US12 • Small Businesses • • • • • • • • • • • • • 2+ years old (generally wouldn't be start-ups in their first year) Income - Have manufacturing costs >$1000 per part. Need - need fast parts made, short runs Education - need to understand hardware end requirements. Work - manufacturing, research, engineering, automotive, etc. Geographical location - in key starting cities, some internet sales. Potential Customer Year 1 Year 2 Year 3 CAGR Sm. Business 100 513 677 61,30% Lg. Business 10 52 68 61,48% Hobbyists 310 1 590 2 098 61,29% Total 420 2 155 2 843 61,30% Large Business 2+ years old • Income - Have manufacturing costs >$1000 per part. Need - need fast parts made, short runs, development iterations Education - need to understand hardware end requirements. Work - manufacturing, research, engineering, automotive, etc. Geographical location - in key starting cities, some internet sales. Hobbyists • • • • • • • • CAGR- Compound Annual Growth Rate 4.2. TARGET MARKET SEGMENT Age - 16 years or older Income - able to afford part costs between $100 and $2000. Need - generally have a concept they want to make or need a replacement part for one that broke Gender - male and female Education - majority expected to have some college and / or trade school Work - professionals and trades Geographical location – key US manufacturing centers / cities, some internet sales. 4.3. GROWTH POTENTIAL • • Additive Manufacturing, aka 3D Printing, will reach $3.1 billion worldwide by 2016 and $5.2 billion by 20208. If 3-DAMTM can capture even 1% of this market that would be $31 million dollars in revenue. 5% growth in revenue the next year would result in $32,550,000 of revenue, per store. 5. THE INDUSTRY - “With 3-DAMTM comes manufacturing freedom!!” • 5.1. COMPETITION - Other companies trying to adopt the “Kinkos” model are: • Mydea Technologies – digital model shop and an additive manufacturing and rapid prototyping provider. http://www.mydeatechnologies.com/ • • • • • • Owners: Michael Siemer Annual Sales: $520K Competitor’s distribution channel: Internet Competitor’s marketing strategy: Internet Sales Products and Services: Product Development & 3-D CAD Modeling, Rapid Prototyping/Additive Fabrication, Subtractive Rapid Prototyping, Rapid Tooling & Manufacturing Competitors price strategy: mid to high cost. • Shapeways – 3D Printing company for designers and Do-It-Yourselfers. Helps people make and sell their items. http://www.shapeways.com/ • • • • • • Owners: Peter Weijmarshausen Annual Sales: $1.90M Competitor’s distribution channel: Internet Competitor’s marketing strategy: Internet Sales, Arts and Crafts forums, Web sales of clients’ products, Do-It-Yourself market. Competitors price strategy: Low to mid cost. Products and Services: Tutorials, Shapeways Lab, Software, Metals and plastic fabrication, Online Sales. • The following companies are a selection that specialize in additive technology and would be competition for their prospective sub-fields: • • • • Morris Technologies - http://www.morristech.com/ – Selective Laser Sintering (SLS) metals C&A Tool - http://www.catool.com/ – SLS metals and machine shop Paramount Industries – http://www.paramountind.com/ - Stereolithography (SLA) and SLS of plastics Materialise - http://manufacturing.materialise.com/ - a Belgian firm that uses additive manufacturing to make a range of products, including medical devices. 6. SALES - “With 3-DAMTM comes manufacturing freedom!!” • 6.1. SALES STRATEGY • It is envisioned that customers would contact a local 3DAMTM business center to initiate a job. • 6.2. PRICE STRATEGY • Pricing would factor in the costs of overhead, materials, and per hour cost for machines and personnel. • A profit mark-up of 30% will be added to each job. • 6.3. PROMOTION STRATEGY • Sales will be generated through advertisement and campaigns. The campaign will utilize TV, trade journals, and the internet (web pages, FaceBook, etc.). • 6.4. SALES FORECAST • Based 3 major products/services: Sales Engineering, Fabricated Metals, and Fabricated Plastics. • Projected the amount of sales revenue generated by the average increase in customers each month times the expected revenue each customer would generate. YR 2 accounts for 4 stores in key cities. YR 3 accounts for 5 stores in key cities. Expect average growth of 12.5% per year for each store. • Cost of sales is the overhead for the sales engineers and technicians plus an estimated monthly operating cost for the metal machines of $4000 and plastic machines of $3000. • These numbers are based upon a best scenario. Sales Year 1 Year 2 Year 3 Sales Engineering 98 000 503 000 664 000 Powder Metal 144 000 740 000 975 000 Powder Plastic 104 000 533 000 704 000 Total sales 346 000 1 776 000 2 343 000 240 000 525 000 620 625 Powder Metal 24 000 70 000 82 750 Powder Plastic 24 000 52 500 62 062 288 000 647 500 765 437 Direct costs, sales Sales Engineering Total, direct costs, sales Sales monthly 7. THE MARKETING PLAN - “With 3-DAMTM comes manufacturing freedom!!” • As part of a Diversification Growth Strategy 3-DAMTM would practice Forward Integration. • As the customer is the focal point for the business model, 3-DAMTM offices will be targeted close to the customers. • Customers will be contacted through advertisement and campaigns. • The campaign will utilize TV, trade journals, and the internet (web pages, FaceBook, etc.). • Highlights of ads will target design freedom, no or low tooling, and speed. • Additionally, small to large manufacturing companies will be approached. • A marketing group will be selected to assist in the marketing campaign on a yearly contract. • A $100k budget will be set for marketing. The marketing campaign will start in June 2013 and continue through December 2013. 8. MANAGEMENT AND EMPLOYEES - “With 3-DAMTM comes manufacturing freedom!!” • CEO / CTO - complete oversight and responsibility for the company as well as technical authority. • CFO - direct oversight of the following reporting line: Accounting, Patient Accounts, Communications, Purchasing, Printing & Duplicating, Information Management, Management Information Systems. • Accounting and Human Resources - Accounting and Human Resources will be outsourced to a 3rd party company and overseen by the CFO. • The company will be responsible for all day to day accounting and human resources activities, including accounts receivable and payable, health and dental care, 401k management, and taxes, etc. The company should have experience with accounting and HR in all US states. It would be preferred if the company has experience with start-up companies. • Technology Team – Materials Engineer, Technology Researcher, Training/Quality • Responsibility for moderately complex engineering projects, • Serves as consultants, providing technical information and engineering recommendations that assist various projects and processes and materials. • Coaches and trains less experienced engineers and technicians. • Branch Manager(s) – oversee branch offices and perform sales • Employees Sales engineers – customer interface, engineers marry up technology to customer needs. There will be 2-3 per store. • CAD and Build technicians – modify designs to make technology friendly, operate and run machines. There will be 1 per machine and two CAD operators per store. • Post processing technicians - provide any necessary post processing and coordination. There will be one per store. • Shipping/Receiving – ship and receive hardware, supplies, etc. There will be one per store. • 9. ACTIVITY PLAN - “With 3-DAMTM comes manufacturing freedom!!” • This section describes some activities that will be needed to implement the • • • • • whole or parts of the business plan. Order and Install Machines – machines and installation at $1,000,000 apiece. 1 plastics, 2 metals, 1 metrology and inspection, 1 oven and autoclave = $5,000,000 Store – 15,000 sq. ft. * $3.523 per foot per year = $52,800. Plus $1,000,000 for upgrades and office requirements. Equals $1,052,800.00 Hire Accounting / HR - $100,000 Supplies - $100,000 Advertising Campaign - $100,000 Activity Start date Stop date Order and Install Machines 03/01/2013 06/01/2013 Store 03/01/2013 Hire Accounting / HR Responsible Department 5 000 000 CTO Technology Team 06/01/2013 1 052 800 CTO CEO 01/02/2013 05/31/2013 100 000 CFO CEO Supplies 03/01/2013 06/01/2013 100 000 CEO CEO Advertising Co. 04/01/2013 06/01/2013 100 000 CEO Branch Managers Total Budget 6 352 800 10. FINANCE AND ECONOMY FIGURES - “With 3-DAMTM comes manufacturing freedom!!” The following are “Seed Capital funding expenses” that will be incurred prior to the business starting: Start-up Costs Research Technology 100 000 Research Store Location 200 000 Permits and Fees 100 000 Marketing Study 100 000 Total Start-up Costs 500 000 Start-up funding Bank Loans 3 000 000 Bank Loans 2 000 000 Other Investors 2 000 000 Grants 2 000 000 Government Loans 1 000 000 Total Start-up funding Total Equity 10 000 000 9 500 000 The following describes all the “Start-up through Second Stage” funding (existing and needed) for the project: Bank Loans – $3,000,000 – Secured against the procured equipment. Equipment, Real-estate, and Long-term loans. Angel Investors – $2,000,000 Other Investors – $2,000,000 – Informal Risk Capital, Venture Capital Grants – $2,000,000 – SBIR - Phase I and Phase II, Fed, State, Local. Government Loans - $1,000,000 – SBA (504, SBA), etc. Total: $10,000,000 Third stage (growth) funding would be necessary for expansion beyond the first store and would be necessary at last quarter 2013. 10. FINANCE AND ECONOMY FIGURES - “With 3-DAMTM comes manufacturing freedom!!” Net profit monthly PROFIT & LOSS TABLE Year 1 Year 2 Year 3 Sales 346 000 1 776 000 2 343 000 Sale costs 288 000 647 500 765 437 --------------BTO profit --------------- --------------- 58 000 1 128 500 1 577 563 17 % 64 % 67 % Salaries 830 004 1 040 000 2 190 000 Additional Salaries costs 273 901 343 200 722 700 0 6 352 800 0 1 210 560 6 052 800 12 105 600 Accounting / HR / Advertising Services 99 996 200 000 200 000 Supplies (office and operating) 99 996 400 000 500 000 Utilities, Web, IT, Phone 20 000 96 000 120 000 Insurance 999 996 4 000 000 5 000 000 Maintenance Plan 100 000 400 000 500 000 Research Technology 100 000 0 0 Research Store Location 200 000 0 0 Permits and Fees 100 000 0 0 Marketing Study 100 000 0 0 BTO profit % Expenses Marketing and activity costs Depreciation --------------Sum direct costs Financial costs Profits before tax Profit before tax % --------------- --------------- 4 134 453 18 884 800 21 338 300 -0 -0 -0 -4 076 453 -17 756 300 -19 760 737 -1 178 % -1 000 % -843 % Net profit yearly 10. FINANCE AND ECONOMY FIGURES - “With 3-DAMTM comes manufacturing freedom!!” Balance Sheet Year 1 Year 2 Year 3 1 297 208 -9 265 893 -22 254 593 346 000 1 776 000 2 343 000 1 643 208 -7 489 893 -19 911 593 Current assets Liquid assets Sales Total current assets Fixed assets YR1 Current Ratio = 0.16 *indicates low liquidity YR2 -1.08 YR3 -1.33 Fixtures and fittings & fixed assets 6 052 800 29 264 000 54 528 000 Debt Ratio = 6.43 -0.92 -0.75 *indicates business while taking on more debt is working out of debt Acc depreciation fixtures & fittings/fixed assets 1 210 560 7 263 360 19 368 960 Debt to Equity = 1.32 *High capital industry/business Total fixtures and fittings/fixed assets 4 842 240 22 000 640 35 159 040 Total assets 6 485 448 14 510 747 15 247 447 Liabilities Share capital & risk capital 10 000 000 10 000 000 10 000 000 Accounts payable 288 000 647 500 765 437 Accrued taxes 273 901 343 200 722 700 Long-term liabilities 0 0 0 Balanced profit/loss 0 -4 076 453 3 520 047 Total liabilities & equity capital 10 561 901 6 914 247 15 008 184 Profit for the year -4 076 453 7 596 500 239 263 Net Profit Margin = -11.78 4.28 *indicates high initial risk but business becoming more stabile. 0.10 ROI = -0.63 0.52 0.02 *indicates high initial risk but business becoming more stabile. 10. FINANCE AND ECONOMY FIGURES - “With 3-DAMTM comes manufacturing freedom!!” CASH FLOW ANALYSIS Liquid assets, incoming Year 1 Year 2 Year 3 10 000 000 6 644 130 -6 790 066 346 000 1 776 000 2 343 000 Liquid assets obtained from activities Sales Other earnings 0 0 0 346 000 1 776 000 2 343 000 612 082 2 859 146 2 479 729 Increase in accounts payable 0 0 0 Increase in short-term liabilities 0 0 0 Increase in long-term liabilities 0 0 0 Sale of current assets 0 0 0 Sale of fixed assets 0 0 0 Total earnings from activities Other liquid assets obtained VAT and tax refunds New capital increase 0 0 0 958 082 4 635 146 4 822 729 Cash expenditure 2 937 992 13 136 300 9 275 437 Total expenditure from activities 2 937 992 13 136 300 9 275 437 323 160 721 842 1 253 200 Reduction in short-term liabilities 0 0 0 Reduction in long-term liabilities 0 0 0 Total liquid assets obtained Liquid assets spent Other liquid assets spent VAT and tax payments Purchase of current assets 0 0 0 Purchase of fixed assets 1 052 800 4 211 200 5 264 000 Total liquid assets spent 4 313 952 18 069 342 15 792 637 -3 355 870 -13 434 196 -10 969 908 6 644 130 -6 790 066 -17 759 975 Net cash flow Liquid assets, outgoing Back Up Slides REFERENCES: 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. "ASTM International Technical Committee F42." ASTM International Technical Committee F42. N.p., n.d. Web. 17 July 2012. <http://www.astm.org/COMMITTEE/F42.htm>. "Designation: F2792 − 12a - Standard Terminology for Additive Manufacturing Technologies." ASTM F2792 - 12a. ASTM, 17 July 2012. Web. 2012. <http://enterprise.astm.org/filtrexx40.cgi?+REDLINE_PAGES/F2792.htm>. "Industrial Space Cost Comparison." Greater Houstono Partnership. Cushman & Wakefield, Third Quarter 2011, 2011. Web. June 2012. <http://www.houston.org/pdf/research/17CW005.pdf>. Kotkin, Joel. "Heavy Metal Is Back: The Best Cities For Manufacturing." Forbes. Forbes Magazine, 15 Dec. 2011. Web. 17 July 2012. <http://www.forbes.com/sites/joelkotkin/2011/12/15/heavy-metal-is-back-the-best-cities-for-manufacturing/>. Liechty, Eli. "Commercial Benefits of Metals Additive Manufacturing for Aerospace Production." Midwest SAMPE. Mar. 2011. Lecture. www.midwestsampe.org/content/files/events/.../Metals%20Liechty.pdf "Manufacturing.GOV." National Network for Manufacturing Innovation (NNMI). N.p., n.d. Web. 17 July 2012. <http://www.manufacturing.gov/amp/pilot-institute.html>. Marcus, Adam. "3D Printing: The Future Is Here." 3D Printing: The Future Is Here. The Technology Liberation Front, 10 June 2011. Web. 17 July 2012. <http://techliberation.com/2011/06/10/3d-printing-the-future-is-here/>. McCue, TJ. "3D Printing Industry Will Reach $3.1 Billion Worldwide by 2016." Forbes. Forbes Magazine, 27 Mar. 2012. Web. 17 July 2012. <http://www.forbes.com/sites/tjmccue/2012/03/27/3d-printing-industry-will-reach-3-1-billion-worldwideby-2016/> McCue, TJ. "Additive Manufacturing Will Change in the Next 5-10 Years." Forbes. Forbes Magazine, 02 May 2012. Web. 17 July 2012. <http://www.forbes.com/sites/tjmccue/2012/05/02/additive-manufacturing-will-change-in-the-next-5-10years/>. Smartplan Generator Ver. 1.5- http://download.cnet.com/Smartplan-Generator/3000-2076_4-10708683.html USA. EXECUTIVE OFFICE OF THE PRESIDENT. EXECUTIVE OFFICE OF THE PRESIDENT. A FRAMEWORK FOR REVITALIZING AMERICAN MANUFACTURING. Http://www.whitehouse.gov/, Dec. 2009. Web. June 2012. <http://www.whitehouse.gov/sites/default/files/microsites/20091216-maunfacturing-framework.pdf>. USA. National Science and Technology Council. Executive Office of the President. A NATIONAL STRATEGIC PLAN FOR ADVANCED MANUFACTURING. Http://www.whitehouse.gov/, Feb. 2012. Web. June 2012. <http://www.whitehouse.gov/sites/default/files/microsites/ostp/iam_advancedmanufacturing_strategicplan_2012.pdf>. Wohlers, Terry. "Worldwide Trends in Additive Manufacturing." RapidTech 2009: US-TURKEY Workshop on Rapid Technologies. Wohlers Associates, Inc, 2009. Web. June 2012. <http://iweb.tntech.edu/rrpl/rapidtech2009/wohlers.pdf>. One Store (Houston, TX) Ratios Current Ratio = *indicates low liquidity YR1 0.16 YR2 -0.10 Debt Ratio = 1.62 3.34 *indicates store is working out of debt YR3 -1.5 0.76 Debt to Equity = 1.32 *High capital industry/business Net Profit Margin = -11.78 -11.74 -10.42 *indicates high initial risk but business working toward stabilizing. ROI = -0.63 -2.34 1.78 *indicates high initial risk but business becoming more stabile.