CE726- Strategic Management in Construction Industry

advertisement

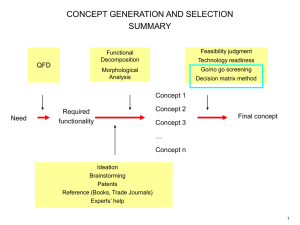

QUALITY FUNCTION DEPLOYMENT (QFD) 05.12.2013 Açelya Ecem Yıldız, Çağıl Köseoğlu CE726- Strategic Management in Construction Industry 1 Table of Contents • • • • • • • • • • • • • • • • • • Introduction History of QFD Definition of QFD Steps of QFD Benefits of QFD Problems regarding the implementation of QFD QFD Resources Functional Fields of QFD Applied industries of QFD Methodological development of QFD Quality Function Deployment in Construction Industry Benefits of QFD in Construction Limitations of QFD in Construction Application of QFD in Construction Industry QFD Application- Example Recommendations for Implementation of OFD in Construction Industry Conclusion References CE726- Strategic Management in Construction Industry 2 Introduction QFD is an ideal opportunity to move away from “we know best what the customer wants” to a new culture of “let’s hear the voice of the customer” (Zairi and Youssef, 1995). Major focuses; customer orientation, cross functional management and process rather than product orientation In the House of Quality as it was named by Hauser and Clausing (1988), the different steps of the planning phase for a new product are summarized. During this phase the customer requirements (WHATs) are translated into design characteristics (HOWs) on the basis of market research and past experiences (the WHY scores) (Govers, 2001) CE726- Strategic Management in Construction Industry 3 History of QFD born in Japan as a strategy for assuring that quality is built into new products first used in 1972 by Kobe Shipyard of Mitsubishi Heavy Industries Ltd the use of QFD in Japan has increased over the years however, its extension to the West was very slow. first examples in the USA did not emerge until 1986 in USA, companies such as Ford and Rank Xerox first introduced it Then, AT&T Bell Labs, Digital Equipment, Procter & Gamble and Hewlett-Packard Countries/regions used QFD in the UK the uptake of QFD is very recent Australia Belgium Brazil Danmark Finland Germany Hong Kong Indıa CE726- Strategic Management in Construction Industry Ireland Israel Italy Japan Korea Malaysia Netherlands Scotland Singapore Slovenia Sweden Taiwan Turkey UK US 4 Definition of QFD Hauser and Clausing (1988) “focuses and coordinates skills within an organization, first to design, then to manufacture and market goods that customers want to purchase and will continue to purchase. The foundation of the [QFD] is the belief that products should be designed to reflect customers’ desires and tastes – so marketing people, design engineers, manufacturing staff must work closely together from the time a product is conceived” Akao (1990) “a method for developing a design quality aimed at satisfying the customer and then translating the customers’ demands in to design targets and major quality assurance points to be used throughout the production phase” CE726- Strategic Management in Construction Industry 5 House of Quality: a 9-step model Step 5 Generate Technical Measures (HOWs) Step 1 Identify Customers & Collect Customer Needs (WHATS) Step 2 Step3 Step 4 Determine Step 6 Identify Competitiors, Determine Relative Determine Conduct Customer Final Importance Relationships Between Competitive Analysis & Set Importance Ratings of WHATs and HOWs Customer Performance Ratings of WHATs Goals for WHATs WHATs Step 7 Determine Initial Technical Ratings of • Based on the study of Hauser and Clausing HOWs (1988) Step 8 • Modification by Chan and Wu (2005) Conduct Technical Competitive Analysis & Set Technical Performance Goals for HOWs Step 9 Determine Final Technical Ratings of HOWs CE726- Strategic Management in Construction Industry 6 House of Quality: Step 1 Step 5 Generate Technical Measures (HOWs) Step 1 Identify Customers & Collect Customer Needs (WHATS) The producing company should know who are the customers for the product concerned. Step 2 Step3 Step 4 Determine Step 6 Identify Competitiors, Determine Relative Determine Conduct Customer Final Importance Relationships Between Competitive Analysis & Set Importance Ratings of WHATs and HOWs Customer Performance Ratings of WHATs Goals for WHATs WHATs Step 7 Determine Initial Technical Ratings of HOWs Step 8 Three types of customers, internal customers (shareholders, Conduct Technical Competitive Analysis managers and employees), intermediate customers (wholesale & Set Technical people and retailers), and ultimate customers (recipients of Performance Goals for HOWs service, purchasers, institutional purchasers) Step 9 Determine Final Technical Ratings of The main focus is on the ultimate customers who could be HOWs identified through previous information and marketing research. Available methods to collect customer needs include focus group, individual interviews, listening and watching, and using existing information. CE726- Strategic Management in Construction Industry 7 House of Quality: Step 2 Step 5 Generate Technical Measures (HOWs) Step 1 Identify Customers & Collect Customer Needs (WHATS) Step 2 Step3 Determine Step 6 Identify Competitiors, Relative Determine Conduct Customer Importance Relationships Between Competitive Analysis & Set Ratings of WHATs and HOWs Customer Performance WHATs Goals for WHATs Step 7 Determine Initial Technical Ratings of HOWs Step 8 Conduct Technical Competitive Analysis & Set Technical Performance Goals for HOWs Step 9 Determine Final Technical Ratings of HOWs Step 4 Determine Final Importance Ratings of WHATs Customer needs (WHATs) usually are of different degrees of importance so focus more on the important WHATs. Expressed as customers perceptions on the relative importance of the WHATs and then averaging their perceptions. The appropriate ways of obtaining customers’ perceptions are by individual interviews and mail surveys. CE726- Strategic Management in Construction Industry 8 House of Quality: Step 3 Step 5 Generate Technical Measures (HOWs) Step 1 Identify Customers & Collect Customer Needs (WHATS) Competitors who produce the similar products should be identified Step 2 Step3 Step 4 Determine Step 6 Identify Competitiors, Determine Relative Determine Conduct Customer Final Importance Relationships Between Competitive Analysis & Set Importance Ratings of WHATs and HOWs Customer Performance Ratings of WHATs Goals for WHATs WHATs Step 7 Determine Initial Technical Ratings of HOWs Knowing the company’s strengths and constraints in all Step 8 Conduct Technical aspects of a product and in comparison with its main Competitive Analysis & Set Technical competitors is important to sustain competitiveness Performance Goals for HOWs Step 9 This kind of information can be obtained by asking the Determine Final Technical Ratings of customers to rate the relative performance of the HOWs company and its competitors on each WHAT and then to aggregate the customers’ ratings. Useful ways of conducting this kind of comparison analysis are also via mailed surveys and individual interviews. CE726- Strategic Management in Construction Industry 9 House of Quality: Step 4 Step 5 Generate Technical Measures (HOWs) Step 1 Identify Customers & Collect Customer Needs (WHATS) Step 2 Step3 Determine Step 6 Identify Competitiors, Relative Determine Conduct Customer Importance Relationships Between Competitive Analysis & Set Ratings of WHATs and HOWs Customer Performance WHATs Goals for WHATs Step 7 Determine Initial Technical Ratings of HOWs Step 8 Conduct Technical Competitive Analysis & Set Technical Performance Goals for HOWs Step 9 Determine Final Technical Ratings of HOWs Step 4 Determine Final Importance Ratings of WHATs Customer needs with higher relative importance perceived by customers and higher competitive priorities and improvement ratios should receive higher attention. CE726- Strategic Management in Construction Industry 10 House of Quality: Step 5 Step 5 Generate Technical Measures (HOWs) Step 1 Identify Customers & Collect Customer Needs (WHATS) Step 2 Step3 Determine Step 6 Identify Competitiors, Relative Determine Conduct Customer Importance Relationships Between Competitive Analysis & Set Ratings of WHATs and HOWs Customer Performance WHATs Goals for WHATs Step 7 Determine Initial Technical Ratings of HOWs Step 8 Conduct Technical Competitive Analysis & Set Technical Performance Goals for HOWs Step 9 Determine Final Technical Ratings of HOWs Step 4 Determine Final Importance Ratings of WHATs The company’s technicians or product development team should develop a set of HOWs to capture the customer needs in measurable and operable technical terms. HOWs could be generated from current product standards or selected by ensuring through cause– effect analysis that the HOWs are the first-order causes for the WHATs CE726- Strategic Management in Construction Industry 11 House of Quality: Step 6 Step 5 Generate Technical Measures (HOWs) Step 1 Identify Customers & Collect Customer Needs (WHATS) Step 2 Step3 Determine Step 6 Identify Competitiors, Relative Determine Conduct Customer Importance Relationships Between Competitive Analysis & Set Ratings of WHATs and HOWs Customer Performance WHATs Goals for WHATs Step 7 Determine Initial Technical Ratings of HOWs Step 8 Conduct Technical Competitive Analysis & Set Technical Performance Goals for HOWs Step 9 Determine Final Technical Ratings of HOWs Step 4 Determine Final Importance Ratings of WHATs The relationship between a HOW and a WHAT is usually determined by analyzing to what extent the HOW could technically relate to and influence the WHAT. All these relationships form a matrix with the WHATs as rows and the HOWs as columns. CE726- Strategic Management in Construction Industry 12 House of Quality: Step 7 Step 5 Generate Technical Measures (HOWs) Step 1 Identify Customers & Collect Customer Needs (WHATS) Step 2 Step3 Determine Step 6 Identify Competitiors, Relative Determine Conduct Customer Importance Relationships Between Competitive Analysis & Set Ratings of WHATs and HOWs Customer Performance WHATs Goals for WHATs Step 7 Determine Initial Technical Ratings of HOWs Step 8 Conduct Technical Competitive Analysis & Set Technical Performance Goals for HOWs Step 9 Determine Final Technical Ratings of HOWs Step 4 Determine Final Importance Ratings of WHATs Initial technical ratings of HOWs are decided by two factors, - final importance ratings of WHATs - the relationships between the HOWs and the WHATs. These ratings indicate the basic importance of the HOWs developed in relation to the WHATs. CE726- Strategic Management in Construction Industry 13 House of Quality: Step 8 Step 5 Generate Technical Measures (HOWs) Step 1 Identify Customers & Collect Customer Needs (WHATS) Step 2 Step3 Determine Step 6 Identify Competitiors, Relative Determine Conduct Customer Importance Relationships Between Competitive Analysis & Set Ratings of WHATs and HOWs Customer Performance WHATs Goals for WHATs Step 7 Determine Initial Technical Ratings of HOWs Step 8 Conduct Technical Competitive Analysis & Set Technical Performance Goals for HOWs Step 9 Determine Final Technical Ratings of HOWs Step 4 Determine Final Importance Ratings of WHATs It is hard to colledct technical parameters and know-hows of the competitors’ products However, the producing company should make every effort to acquire this information to not fail! If technical parameters of competitors’ products could not be obtained, careful technical assessments should be made to give reliable scores CE726- Strategic Management in Construction Industry 14 House of Quality: Step 9 Step 5 Generate Technical Measures (HOWs) Step 1 Identify Customers & Collect Customer Needs (WHATS) Step 2 Step3 Determine Step 6 Identify Competitiors, Relative Determine Conduct Customer Importance Relationships Between Competitive Analysis & Set Ratings of WHATs and HOWs Customer Performance WHATs Goals for WHATs Step 7 Determine Initial Technical Ratings of HOWs Step 8 Conduct Technical Competitive Analysis & Set Technical Performance Goals for HOWs Step 9 Determine Final Technical Ratings of HOWs Step 4 Determine Final Importance Ratings of WHATs higher initial technical ratings, higher technical competitive priorities and higher improvement ratios indicate working focuses and market opportunities for Those HOWs with the producing company !!!! CE726- Strategic Management in Construction Industry 15 Benefits of QFD Zairi and Youssef (1995) and Zucchelli (1992) To define product specifications meeting the customer’s requirements, while paying attention to the competitors To ensure consistency between the customer’s requirements, and the measurable characteristics of the product To inform and convince all those responsible for various stages of the process of the relationship between the quality of the output of each phase and the quality of the finished product To ensure consistency between the planning and the production process To get things moving more quickly because planning takes place at an earlier stage and mistaken interpretations of priorities and objectives are minimized CE726- Strategic Management in Construction Industry 16 Benefits of QFD Akao (1990) QFD enables organizations; To translate customer requirements into meaningful (technical) requirements at each stage of the development and production processes. To offer a structured method to tap into all the knowledge on NPD in any organization and facilitates its management and control. To bring people together from various disciplines and facilitates the formation of teams capable of meeting customer requirements. CE726- Strategic Management in Construction Industry 17 Problems regarding the implementation of QFD Ernst & Young identified the following problems associated with QFD implementation: Engineers think that QFD is a “false science”, too focused on the mechanics of scoring. QFD however is an effective tool of capturing and displaying data and serves as a communication vehicle for generating structured discussions among team members, in order to meet customer requirements (the expertise is in the hands of the team members and not the tool!). It takes a long time to develop a QFD chart fully. Team members get caught in the details of the exercise while the market window closes on them CE726- Strategic Management in Construction Industry 18 Problems regarding the implementation of QFD Hewlett-Packard identified the following problems during the implementation of QFD Project scheduling (time to market) ruling as the dominant consideration. Inadequate management commitment Looking for high return on investment with the first application of QFD. Lack of adequate facilitation: • not timely; • not continued long enough; • not skillful enough in facilitation • not trained well enough in QFD. Taking on too large a product (especially if a first QFD project). Getting into too much detail (QFD tables become unmanageably large). CE726- Strategic Management in Construction Industry 19 QFD Resources - Organizations Organizations Applied Marketing Science http://www.ams-inc.com ASI Quality Systems Ltd. http://www.asiqs.co.uk Becker and Associates http://www.becker-associates.com C2C Solutions http://www.c2c-solutions.com CSP International http://www.csp.fr DRM Associates http://www.npd-solutions.com INFOnetics http://www.infonetics.net Innovation Process Management http://www.ipm-marketing.co.uk INSYTEC B.V. http://www.insytec.com J.H.Berk and Associates http://www.jhberkandassociates.com Learn Firm.com http://www.learnfirm.com PQM http://www.pqm.cz ProAction Development http://www.proactdev.com Quality Associates International http://www.qualityone.com Quality Improvement International http://www.qualityi2.com Vicente Luz Consultores Associados Ltda. http://www.vluz.com.br CE726- Strategic Management in Construction Industry Based on the study of Chan and Wu (2002) 20 QFD Resources – Software/websites/discussion groups QFD Software QFD for Software Evaluation (by Fawsy Bendeck of Universitat Kaiserslautern, Germany QFD Designer (by Qualisoft/Fulfillment Services, USA: QFD Scope (by Integrated Quality Dynamics, US QFD/CAPTURE (by International TechneGroup, US: QFD2000 (by Total Quality Software, UK Qualica QFD (by QualicaSoftware, Germany: VOCALYST (by Applied Marketing Science, US http://www.agr.informatik.unikl.de/ bendeck/qfd/index.html), http://www.qualisoft.com http://www.iqd.com Based on the study of Chan and Wu (2002) http://qfdcapture.com) http://www.qfd2000.co.uk http://www.qualica.de http://www.ams-inc.com Websites /discussion groups Quality Resources Online Quality Resources Online QFD discussion forum University of Sheffield's QFD homepage G.H.Mazur s QFD articles DRM Associates ProAction Development (http://www.quality.org/lists/qfdl.info.txt (http://quality.org/html/qfd.html http://www.jiscmail.ac.uk/lists/qfd.html http://www.shef.ac.uk/ ibberson/qfd.html http://mazur.net http://www.npd-solutions.com (http://www.proactdev.com CE726- Strategic Management in Construction Industry 21 Functional fields of QFD FUNCTIONAL FIELDS APPLICATIONS 1. Product Development development of courses/curriculums, model-change products, new products, products and processes, etc. 2. Quality Management expert systems for quality management, process improvement, quality control, quality information systems, etc. 3. Customer Needs Analysis collecting/translating customer needs, satisfying customer needs, customer involvement, customer preference, etc. 4. Product Design 3D geometry-based product design, robust design, design of information systems and services, flight control design, housing design, etc. 5. Planning product planning, strategic marketing planning, supply chain planning, business process planning, etc. 6. Engineering knowledge intensive engineering, value engineering, rehabilitation engineering, strategic reengineering, etc. 7. Decision-making manufacturing strategies, measuring customer satisfaction, productivity of technology, performance measurement, etc. 8. Management management of advanced manufacturing enterprises, radar-based position reporting systems, customer–supplier relationships, business processes, etc. shorter design cycles, information sharing/internal communications, cross-functional cooperation, 9. Teamwork, timing, etc. costing, and others CE726- Strategic Management in Construction Industry 22 Applied industries of QFD 1.Transportation and Communication 2.Electronics and Electrical Utilities Shipbuilding aircraft, airline Hewlett-Packard IBM automotive parts, car audio commercial vehicles container port Intel Motorola Philips motors railways pedestrian crossings satellite communications transportations voice mail system automated teller machines blend door actuators chip climatic control systems robotic computers hard disk drives integrated circuit work cell sensor battery gas burners power systems wind turbines 3.Software Systems decision support systems expert systems human-machine interface information systems integrated systems management information systems profiling systems web pages Based on the study of Chan and Wu (2002) CE726- Strategic Management in Construction Industry 23 Applied industries of QFD 4. Manufacturing assembly lines/plants/stations bearing braking systems capital goods chocolate composite material computer-integrated manufacturing 5. Services 6. Education and Research meat accounting colleges/universities medical devices metals metrology probes pea pencils administration banking contracting process engineering services food distribution distance education educational institutes kindergartens public schools training plastic components government services vocational secondary schools hotels business schools engine filters equipment food power protection equipment printing instrumentation tea on-line bookshops mortgage professional services research program design furniture quick release top nozzles public sectors helmet-mounted displays safety shoes real estate appraisal cork removers CE726- Strategic Management in Construction Industry Based on the study of Chan and Wu (2002) 24 Methodological development of QFD 1. Quantitative methods for QFD Management Science/Operational Research Analytic hierarchy process (AHP) to prioritize customer needs (whats) Marketing Research collecting customer needs by videotaping AHP and benchmarking integrated to rate ‘‘whats’’ conjoint analysis AHP and QFD for combining customers’ requirements and preferences AHP and two multi-attribute decision-making methods for rating ‘‘whats’’ non-linear mathematical program for determining the optimal ‘‘hows’’ during new product development fuzzy logic-based extension to QFD fuzzy logic based simplification of QFD process in QFD fuzzy method for prioritizing ‘‘hows’’ in QFD intensity-polarity voting model to generate group positions fuzzy multi criteria methods for QFD marketing’s lead role in QFD AHP to study the ranking sensitivity of ‘‘whats’’ in QFD optimization model to minimize the ranking variability of ‘‘hows’’ combining aggregate complaint analysis and QFD marketing research methods for collecting and analyzing ‘‘whats’’ in QFD new technologies for listening to the voice of the customer nominal group technique sessions and interviews to define ‘‘whats’’ comparative study of the prioritization matrix and AHP methods in QFD fuzzy inference-based QFD to determine design targets customer satisfaction benchmarking Value functions to capture ‘‘whats’’ three MS/OR methods for prioritizing design rules Fuzzy Logic CE726- Strategic Management in Construction Industry fuzzy ranking procedure for implementing QFD fuzzy outranking approach to prioritize ‘‘hows’’ in QFD fuzzy QFD framework fuzzy QFD mechanism for assessing system reliability fuzzy QFD model for deriving optimal target values of ‘‘hows’ 25 Methodological development of QFD 2. Extensions and implementation issues of QFD Extensions and implementation issues of QFD combining QFD and failure mode effects analysis comprehensive QFD, computational QFD software QFD statistically extended QFD QFD’s practical issues have been well discussed to increase the usability of QFD, such as conditions and prerequisites to effective QFD concurrent function deployment extending QFD’s ‘‘quality plans’’ to several lifecycle ‘‘value sets’’ difficulties and issues associated with QFD cost, reliability, and technology incorporated into QFD effects of different deployment teams of QFD on quality and cost in product development design costs integrated into QFD to optimize product development resources distributed QFD dynamic QFD with feedback loops Enhanced QFD factors for successful implementation of QFD how QFD can be used and some of its problems how to capture true customer needs how to analyze conflicting customer needs how to use templates to eliminate repetitive project setup in expert system-based extension to the fuzzy QFD methodology QFD/Capture extended QFD implementation issues of QFD extended QFD process for ecologically sustainable product design implications of research results for QFD four-stage model for performing software-oriented QFD key factors in the successful application of QFD CE726- Strategic Management in Construction Industry» 26 Methodological development of QFD 3. Comparative studies, surveys, and reviews on QFD Comparative studies, surveys and reviews on QFD case-based comparison of two QFD models for product development comparison of communication patterns of two new product development teams with and without QFD comparison of QFD and decision analysis for making multi-objective product design decisions comparison of QFD and other concurrent engineering tools used in UK industry comparison of QFD and other methods for generating valid customer needs ( comparison of QFD and other new product development procedures comparison of QFD and other software measurement methods comparison of QFD uses and benefits in the US and Japan comparison of traditional QFD and multi-criteria decision aid-based QFD differences between the Japanese and Western QFD practices effects of incentive schemes and organizational structures on new product development process of firms with and without QFD QFD survey of 33 firms and results recent aspects of QFD in Japanese software industry review of QFD and its applications review of QFD and its customary practice around the world review of QFD and its practice in the Netherlands review of QFD and other methods for customer involvement in product development review of QFD in the food industry survey and analysis of 35 QFD projects at nine US firms survey and analys is of QFD’s applications in US automotive industry survey and analysis of QFD’s uses, benefits, and implementation problems in the UK survey of 80 QFD projects and analysis of QFD’s benefits and implementation issues Based on the study of Chan and Wu (2002) CE726- Strategic Management in Construction Industry 27 Quality Function Deployment in Construction Industry QFD is widely used in manufacturing and developing new products with high customer satisfaction. Implementation of QFD in the construction industry is rather scarce. (Schriener et al., 1995) Survey results showed that; (Delgado- Hernandez et al., 2007) Awareness of QFD was still little in the construction sector and only 18% respondents knew the tool. CE726- Strategic Management in Construction Industry 28 Definition of Quality & Customer Quality: Quality in the construction industry: “meeting the requirements of the designer, constructor and regulatory agencies as well as the owner.” (Arditi and Gunaydin,1997) Customers: "the first step in quality planning is to identify who are the customers". (Juran, 1988) Therefore, understanding of the concept of customer is crucial to the application of QFD. In construction industry, interchanging relations between designer, contractor, owner and buyers. CE726- Strategic Management in Construction Industry 29 Quality in Construction Industry Differences in construction industry compared to manufacturing; (Rounds and Chi, 1985) Uniqueness of each construction project Different site conditions of each construction production The life-cycle of a construction project is much longer Construction projects usually are evaluated subjectively as there is no clear and uniform standard in evaluating overall construction quality The owner usually directly influences the production The participants in the construction project differ for each project. CE726- Strategic Management in Construction Industry 30 Benefits of QFD in Construction Precise collection and identification of client needs/expectations (Oswald and Burati, 1992; Tran and Sherif, 1995) Better planning Enhanced communication (Griffin and Hauser, 1992; Kamara et al., 2000) Reduced uncertainty (Kamara et al., 2000) Chan and Wu reported (Chan and Wu, 2002) • 30–50% reduction in engineering changes • 30–50% shorter design cycles • 20–60% lower start-up costs • 20–50% fewer warranty claims CE726- Strategic Management in Construction Industry 31 Limitations of QFD in Construction Limitations in construction projects; (Dikmen et al., 2005) Global limitations: lack of awareness about QFD it mainly quality based and lacks comprehensiveness in terms of project constraints (Pheng and Yeap, 2001) it does not consider the strategic objectives HOQ matrix is mainly done by subjective judgments it is more useful for D/B project (a single party is responsible for every phase) Application-specific limitations: team becomes important requires time, resource and effort for large construction projects Pheng and Yeap suggested use of four HOQ matrices of subprojects (Pheng and Yeap, 2001) CE726- Strategic Management in Construction Industry 32 Limitations of QFD in Construction (Pheng and Yeap, 2001) CE726- Strategic Management in Construction Industry 33 Application of QFD in Construction Industry Construction Industry has been slow in adopting the methodology, most of them in design of flats. (Delgado-Hernandez et al. 2007) Surveys have been conducted to evaluate the awareness of QFD in construction industry: Pheng saw that approximately 7% of the sample size has heard of QFD. (Pheng and Yeap, 2001) Chia reported that the awareness of QFD among professionals, mainly architects and engineers was approximately 10% of the sample size. (Chia, 1999) Delgado-Hernandez et al. showed that only 18% respondents knew the OFD tool. (Delgado-Hernandez et al. 2007) CE726- Strategic Management in Construction Industry 34 Application of QFD in Construction Industry Applications in the literature are grouped under three categories; (Dikmen et al., 2005) QFD implementations before the design stage: Arditi and Lee used QFD tool for the selection of D/B firms (Arditi and Lee, 2003) QFD implementations during the design stage: Mallon and Mulligan introduced the construction literature with QFD and demonstrated applicability of QFD in design of a hypothetical renovation project of an existing computer workroom facility. (Mallon and Mulligan, 1993) Huovila et al. Used the method for structural design of an industrial building. (Huovila et al., 1997) Serpell and Wagner applied the HOQ to determining design characteristics of flats in Chile. (Serpell and Wagner, 1997) Abdul-Rahman et al. applied it to identify the most important consumer requirements, evaluate current status of low-cost flats and improvements for future projects. (Abdul-Rahman et al., 1999) CE726- Strategic Management in Construction Industry 35 Application of QFD in Construction Industry Gargione used HOQ in Brazilian construction industry to improve design of a middle-class flat and changed the design of an apartment accordingly. (Gargione, 1999) Kamara et al. applied QFD for processing client requirements and determined the actual requirements for a building refurbishment project. (Teesside Innovation Centre at the University of Teesside) (Kamara et al., 1999) Eldin and Hikle applied QFD in development of the design for a modern university classroom. (Eldin and Hikle, 2003) Benefits were reported: critical decisions made on time, the elimination of rework and design flaws, and clear definition of customer needs. The process made it possible for a group of individuals with different interests to listen clearly to the customers’ needs, communicate their needs, find and approve critical decisions on time. CE726- Strategic Management in Construction Industry 36 Application of QFD in Construction Industry Delgado-Hernandez studied the method on determining important factors in the design of a new children’s nursery in the UK. QFD was successful especially at the early stages of the construction in identifying customer needs, determining technical characteristics and enhancing communication with customers. (Delgado-Hernandez et al., 2007) Pheng and Yeap studied a hypothetical personal computer workroom facility upgrading project at a university to decide if improvements are desirable or needed and elements for improvements. (Pheng and Yeap, 2001) CE726- Strategic Management in Construction Industry 37 QFD Application- Example QFD implementations after the design stage: Dikmen at al. studied use of QFD after the construction stage. They applied QFD in Turkish construction industry using HOQ method to a high-rise housing project for guiding their marketing plans. (Dikmen et al., 2005) Hauser and Clausing, 1988 CE726- Strategic Management in Construction Industry 38 QFD Application- Example Step 1 customer profile of the project was defined (company professionals) middle&high income people looking for differentiation in housing units Step 2 expectations of the target customer profile was identified customer surveys, interviews feedbacks from previous projects interdisciplinary research team was constructed for expert opinions important criteria for customer satisfaction VOC section was constructed (section 1) CE726- Strategic Management in Construction Industry Dikmen et al., 2005 39 QFD Application- Example Step 3 importance level of needs have been decided by considering previous customer priorities by considering compatible projects subjective customer evaluations for rivals were included with 1-5 scale importance levels by considering rival companies’ evaluations planning matrix was formed (section 3) Dikmen et al., 2005 CE726- Strategic Management in Construction Industry 40 QFD Application- Example Step 4 technical measures were identified (solutions to each customer need) by brainstorming sessions (section 2) relationships between customer needs and technical measures were identified (section 4) subjectively by the research team scoring scale of 9, 3, 1 and 0 (from strong to no relationship) CE726- Strategic Management in Construction Industry 41 QFD Application- Example Step 5 performance of company compared with rivals’ performance need of improvements& goals for meeting weights of each need were calculated and weight of unsuccessful need is increased (attention) ‘‘availability of sufficient green area for recreational purposes’’ CE726- Strategic Management in Construction Industry 42 QFD Application- Example Step 6 interactions between technical measures are induced in the roof of the matrix (section 5) -/+ correlation weights of technical measures have been calculated (Σ customer need weight x relationship score) measures that need improvement identified CE726- Strategic Management in Construction Industry Dikmen et al., 2005 43 QFD Application- Example CE726- Strategic Management in Construction Industry 44 QFD Application- Example Results of the case study were listed in terms of; five most important technical measures for project success location of the housing complex functional architectural layout of the apartment units total size of each apartment unit security system/Professional security team area reserved for recreational purposes/good sight three most important customer demands social differentiation large apartment units Security from external threats CE726- Strategic Management in Construction Industry 45 QFD Application- Example three most significant customer needs have been ranked as; security from external threats parking area/garage sufficient green area for recreational purposes highest contributors in the overall success of the project are; total size of each apartment unit location of the housing complex company assigned for the operation and maintenance of the complex Evaluation of the results the study satisfied the company professionals; see customer requirements & rival performance structured way the company decided to use the QFD methodology in future projects later on an interview has been conducted after 1.5 years, according to this the company used the outputs in a new housing project marketing strategy reduced the selling period of the housing units CE726- Strategic Management in Construction Industry 46 Recommendations for Implementation of OFD in Construction Industry reliability of the model would improve by; considering cost and schedule constraints subjective relationships and weights assignment should be imposed by quantitative methods such fuzzy logic for successful application of the method; computer applications for timely concerns, trainings and seminars to increase knowledge application at earlier stages to prevent late changes, missing important client requirements careful definition of the QFD team for reliable outputs from the HOQ matrix Dikmen et al., 2005 CE726- Strategic Management in Construction Industry 47 Conclusion Customer's requirements and their relationships with design characteristics are the driving forces of QFD methodology. (Govers, 2001) QFD enables an organization to build a quality into the product and to control the development process from concept to the commencement of manufacturing operations. (Govers, 2001) QFD has been successful in manufacturing and developing new products and a large number of companies in many industries are using QFD. However, unlike these industries the number of companies that attempted the implementation of QFD in the construction industry is rather scarce. CE726- Strategic Management in Construction Industry 48 Conclusion In implementation, method has certain global and application-specific limitations; such as ignoring project constraints, lack of awareness and formation of complex matrices. Many researchers found that the methodology improved both the project definition process and the identification of customer requirements while reducing time and enhancing functional communication. CE726- Strategic Management in Construction Industry 49 References • • • • • • • • • • • • Zairi, M., Youssef, M.A. (1995). Quality function deployment: a main pillar for succefful total quality management and product developmet. International Journal of Quality and Reliability Management, 12(6), 9-23. Hauser, J.R. and Clausing, D., “The house of quality”, Harvard Business Review, May-June 1988, pp. 63-73. Govers, C.P.M. (2001), QFD not just a tool but a way of quality management, International Journal of Production Economics, 69, 151159. Y. Akao, (Ed.), Quality Function Deployment, Integrating Customer Requirements into Product Design, Productivity Press, Cambridge, MA, 1990 Chan, L.K., and Wu, M.L. (2005). A systematic approach to quality function deployment with a full illustrative example. Omega, 33, 119-139. Zucchelli, F., “Total quality and QFD”, 1st European Conference on Quality Function Deployment, Milan, 25-6 March 1992, Galgano & Associati. Chan, L.K., and Wu, M.L. (2002). Quality function deployment: A literature review. European Journal of Operational Research 143, 463–497 Abdul-Rahman, H., Kwan, C.L., Woods, P.C. (1999), Quality Function Deployment in Construction Design: Application in Low-cost Housing Design, International Journal of Quality & Reliability Management, Vol. 16 No. 6, pp. 591-605. Arditi D, Lee D. (2003), Assessing the corporate service quality performance of design-build contractors using quality function deployment. Construction Management and Economics;21: pp. 175–85. Chia, C. H. (1999), ‘‘Application of quality function deployment in design and construction.’’ BSc dissertation, School of Build. and Real Estate, National University of Singapore, Singapore. Delgado-Hernandez, D.J., Bampton, K.E., Aspinwall, E. (2006), Quality Function Deployment In Construction, Construction Management and Economics, 25; pp. 597-609. Dikmen, I., Birgonul, M.T., Kiziltas, S., (2005), Strategic Use of Quality Function Deployment (QFD) In The Construction Industry, Building and Environment, 40; pp. 245-255. CE726- Strategic Management in Construction Industry 50 References • • • • • • • • • • • • • Eldin, N., Hikle, V. (2003), Pilot Study of Quality Function Deployment in Construction Projects, Journal of Construction Engineering and Management, Vol. 129, No. 3, pp. 314-329. Ferguson, H. and Clayton, L. (Eds) (1988), Quality in the Constructed Project: A Guideline for Owners, Designers and Constructors, Vol 1. ASCE, New York. Hauser, J. R., and Clausing, D. (1988), The house of quality. Harvard Bus. Rev., 66; pp. 63–73. Huovila P, Lakka A, Laurikka P, Vainio M. (1997), Involvement of customer requirements in building design. In: Alarcon L, editor. Lean construction. Rotterdam: Balkema; pp. 403–416. Juran, J.M. (1988), Juran on Planning for Quality, The Free Press, New York, N.Y. Kamara JM, Anumba CJ, Evbuomwan FO. (1999), Client requirements processing in construction: a new approach using QFD. Journal of Architectural Engineering;5(1): pp. 8–15. King, R. (1989), Better designs in half the time. 3rd ed., GOAL/QPC, Methuen, Mass. Mallon, J.C., Mulligan, D.E., (1993), Quality Function Deployment- A System For Meeting Customers Needs, Journal of Construction Engineering and Management, 119: pp. 516-531. Pheng LS, Yeap L. (2001), Quality Function Deployment in Design/ Build Projects, Journal of Architectural Engineering; 7(2): pp. 30– 39. Rounds, J. L. and Chi, N. Y. (1985), TQM for construction. Journal of Construction Engineering and Management, 111(2), pp. 117-127. Schriener, J., Angelo, W., and McManmy, R. (1995). Total quality management struggles into orbit.Eng. News-Rec., 15, pp. 24–28. Serpell A, Wagner R. (1997), Application of quality function deployment (QFD) to the determination of the design characteristics of building apartments. In: Alarcon L, editor. Lean construction. Rotterdam: Balkema; pp. 355–363. Tran TL, Sherif JS. (1995), Quality function deployment (QFD): an effective technique for requirements acquisition and reuse. Proceedings of IEEE int. software engng. standard symposium, Los Alomitos, CA. CE726- Strategic Management in Construction Industry 51