House of Quality

advertisement

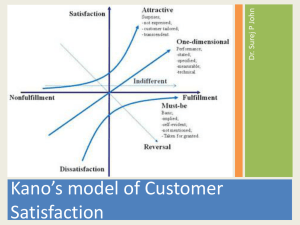

House of Quality Example • An interactive HOQ example – by Professor Robert Hunt, C/-Macquarie University Graduate School of Management Macquarie University New South Wales Australia • HOQ template Key to roof / correlation matrix symbols + Positive / Supporting - Negative / Tradeoff Metrics calculation - + - + + DIRECTION OF IMPROVEMENT Performance measures TECHNICAL REQUIREMENTS Size of range Technical details PLANNING MATRIX CUSTOMER REQUIREMENTS Easy to put on 2 3 3 4 4 1.2 1.1 2.6 Comfortable when hanging 5 4 4 2 5 1.2 1.4 8.4 22 Fits over different clothes 1 1 1 5 2 1.2 1.0 1.2 3 Accessible gear loops 3 3 4 1 3 1.0 1.0 3.0 8 Does not restrict movement 5 2 2 3 5 1.6 1.4 11.2 29 Lightweight 3 3 2 5 3 1.0 1.0 3.0 Safe 5 4 3 3 4 1.0 1.2 6.0 16 Attractive 2 2 2 5 3 1.2 1.1 2.6 TECHNICAL PRIORITIES 54 81.2 63 23.4 70.2 191.6 98.6 30 PERCENTAGE OF TOTAL 9 10 4 12 Our product Y 174g 250 5 Competitor A's product Y 193g 321 Competitor B's product DESIGN TARGETS 13 31 7 8 7 Key to interrelationship matrix symbols 16 5 Strong interrelationship 4 4mm 1 4 Medium interreltionship 3 5 8mm 4 5 Weak interrelationship Y 157g 198 6 4 3mm 1 3 Y 160g 250 8 6 4mm 2 4 Priorities calculation Kano’s Model • Reference: Integrating Kano’s model in the planning matrix of quality function deployment; K.C. Tan, X.X. Shen, Total Quality Management, Vol:11 No:8 (2000) 1141-1151 • The quality of a product/service determined by customer satisfaction factor this into the planning matrix of the QFD process • Kano’s model characterizes three distinct attributes through which the customer satisfaction is affected Attractive Satisfaction One-dimensional Must-be Performance Kano’s Model • One-dimensional attributes: customer satisfaction is proportional to the level of performance. Ex: mileage/gallon for a new car • Attractive attributes: criteria will greatly, positively influence the satisfactory level of customers. Ex: add-on features of a car, GPS system, etc.. • Must be attributes: criteria must have for a product. These are usually taken for granted and the fulfillment of these will not lead to more satisfaction. Ex: safety of a product, seat belt/airbag • It can be integrated into the QFD by modifying the Improvement ratio (IR) using the following formula – (IR)adjusted=(IR)k, where k is a parameter determined by the designer – k=1/2 for Must be, =1 for One-D, =2 for Attractive – IR is calculated directly as the ratio between the planned rating (PR) and our product (OP) – Ex: item 5: IR=5/2=2.5, this is a must-be for the customer, use k=1/2 (2.5)1/2=1.58, close to the IF=1.6 used. item 1: IR=4/3=1.3, it is deemed an attractive attribute, use k=2 (1.3)2=1.8 higher than IF=1.2 using the original formula Application of QFD process sequentially to structure product, part, process, and production Process Planning Production characteristics Part Design Process characteristics Product Planning Part characteristics Engineering characteristics Targets Customer requirements Production Planning