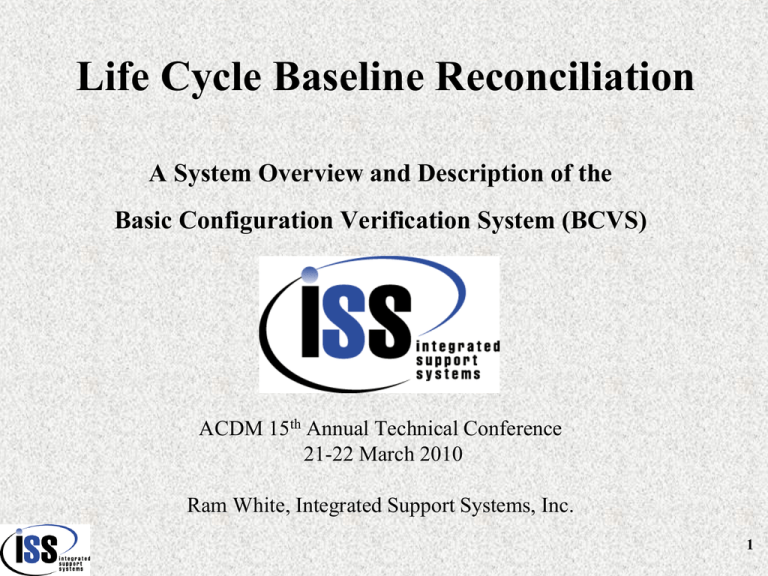

Life Cycle Baseline Reconciliation

advertisement

Life Cycle Baseline Reconciliation A System Overview and Description of the Basic Configuration Verification System (BCVS) ACDM 15th Annual Technical Conference 21-22 March 2010 Ram White, Integrated Support Systems, Inc. 1 Life Cycle Baseline Reconciliation Basic Configuration Verification System (BCVS) Presentation Agenda: • The Basics/Fundamentals – • • The BCVS Business Values The System Environments – – • • Functional Systems Architectures Communications (point-to-point or Standards) Data Object Modeling (The devil is in the detail) Data Mapping Strategies – • • • Product Life Cycle, Bills of Material, Data/Documentation, Baselines and BL Comparisons, Audits and Reconciliation XLS/CVS, XML, Standards & Direct Integration ISS/InSync Proposed Solution Supporting the DD 250 Process The Back Story: Boeing’s SI/BCA & P-8A 2 As-Authorized (_________) Product’s Life Cycle Management Cost Estimating Capacity Planning & Assessment Specifications As-Committed (_________) (Basic Life Cycle Process) Master Schedule Work Breakdown Structure Budgets Sales Orders Cost Accounts Effectivity Baseline Release Document Control Product Definition EBOM Bill of Routings Effectivity (Eng.) MBOM Effectivity (Manf.) Bill of Routings/Resources Master Production Schedule Proposed Capacity Planning MRP/CRP/Procurement Work Order Release As-Designed (_________) As-Planned (_________) As-Purchased (_________) Product Structure (Bill of Material) CSCI CSC As-Delivered (_________) CI Item CSC Item Number -1 -3 Unit Unit Unit Unit Part Part Item Number As-Tested (_________) Drawing(s)/Doc(s)/Std(s)/Spec(s) HW/SW/Tooling/Planning Costs/Schedule(s)/Personnel/ Organizations Files/Records/Data/CAD Model(s) Associations/Attributes (FN, NSN, MS, UM, Qty, etc.) As-Built (_________) As-Built Snapshot CM Reconciliation CM Status Accounting Lot Code / Serial Numbering Deviations / Waivers As-Maintained (_________) Receiving/Inspection Receiving Instructions Dock-to-Stock Inventory (WIP) Lot Code / Serial Numbering Shop Floor Control Labor Collection Work Measurements Process Instructions Test Procedures Test Results CM Status Accounting Field Return / Retrofit Field Service CM Reconciliation Lot Code / Serial No. CM Status Accounting As-Built History As-Disposed (_________) Storage, Salvage To-Become (Recycle) CM Reconciliation Lot Code / Serial No. CM Status Accounting As-Was/Is History 3 Product Life Cycle Management Concept Definition Disposal AsDisposed AsCommitted AsMaintained Design Upgrades Detailed Development AsAuthorized AsDesigned AsPlanned AsDelivered PreProduction AsBuilt Deployment/ Operation Production 4 Traditional Life Cycle Reconciliation AsAuthorized AsCommitted AsDesigned AsPlanned AsBuilt AsSupported Authorize Data Schedule Data Design Data Plan Data Build Data Support Data Authorized Baseline Baseline Compares Scheduled Baseline Baseline Compares Design Baseline Planned Baseline Built Baseline Supported Baseline Baseline Compares Baseline Compares Baseline Compares Baseline Compares Comparison Reports Comparison Reports Comparison Reports Comparison Reports Comparison Reports Configuration Audits Configuration Audits Configuration Audits Configuration Audits Configuration Audits Multiple Manual Methods – The Usual 5 Product Life Cycle Management Concept Definition Master Data Repository/Vault Disposal (IDs, Baselines, Changes, CSA, Audits, Etc,) AsAuthorized AsCommitted Configuration (Audit) Reconciliation AsDesigned AsDisposed AsMaintained Design Upgrades AsSupported AsDelivered Deployment/ Operation AsBuilt Detailed Development AsPlanned AsTested PreProduction Production 6 Generic Life Cycle Reconciliation Bills of Material (BOMs) Configuration Reconciliation Accounting and Audit Process (CRAAP) AsAuthorized AsCommitted AsDesigned AsPlanned AsBuilt AsSupported Authorize Data Schedule Data Design Data Plan Data Build Data Support Data Configuration Reconciliation Accounting and Audit Process Authorized Baseline Baseline Compares Comparison Reports Scheduled Baseline Baseline Compares Design Baseline Planned Baseline Built Baseline Supported Baseline Baseline Compares Baseline Compares Baseline Compares Baseline Compares Comparison Reports Comparison Reports Comparison Reports Comparison Reports 7 Product’s Life Cycle Management (Basic Configuration Reconciliation Process) As-Authorized As-Committed (_________) (_________) As-Designed (_________) As-Planned _________) As-Built (_________) As-Maintained (_________) As-Disposed (_________) Marketing Contracts EBOM Structure MBOM Structure OBOM Structure RBOM Structure DBOM Structure Engineering Material Catalog Processes Manufacturing Material Catalog Processes Routings Resources Tooling Operational Processes Routings Resources Tooling Serial Number Lot Code QA/MRB Service Records Retrofit Processes Routings Resources Tooling Serial Number Lot Code QA/MRB As-Built History Repair/Refurbish Records Disposed Processes Resources Serial Number Lot Code As-Was/Is History Storage, Salvage Disposal Records Recycling WBS Budgets Sales Orders Computer-Aided Engineering Engineering Release Configuration Audit(s) Reconciliation 8 Basic Configuration Verification System Business Values: • Ensure Released Drawing Defined Parts are in the AsDesigned. • Ensure the As-Designed Parts are in the Manufacturing Plans and Orders. • Ensure the As-Designed Parts in the Manufacturing Orders and applicable serialization is identified. • Ensure applicable Change information is related to the life cycle views of the product definition. • Enable Part Restriction Documentation and Evolution to be managed and maintained. • Provide a common infrastructure to report and review “Configuration Verification Action Items” in the various life cycle states. 9 Life Cycle Generic System Architecture Manufacturing As-planned (Planning) CAPP System As-built (Orders) BOM System (__________) (__________) SFC System NCM System CA System (__________) (__________) (__________) Part Test & Certification System Engineering Fielding CAD & PDM System CSAR CLS System (__________) As-designed (Parts & BOM) CAE Schedule System CAD-E System (________) (__________) As-designed (Electrical) As-committed (Schedules) (__________) As-supported (Parts/Locations) Program Mgmt. System (________) As-authorized (Contract & Changes) CSA Reports Legend: CAPP - Computer-aided Process Planning BOM - Bill of Material SFC - Shop Floor Control NCM - Number Control Machine CA - Corrective Action CAD-E - Computer-aided Design Electrical CAD - Computer-aided Design PDM – Product Data Management Computer-aided Engineering CLS - Contractor Logistic Support Life Cycle Generic System Architecture Manufacturing BOM System As-built (Orders) NCM System CA System CAPP System SFC System (__________) (__________) (__________) (__________) As-planned (Planning) (__________) Part Test & Certification System Engineering Fielding CAD & PDM System CSAR CLS System (__________) (__________) As-designed (Parts & BOM) CAD-E System (__________) As-designed (Electrical) CAE Schedule System (________) As-committed (Schedules) As-supported (Parts/Locations) Program Mgmt. System (________) As-authorized (Contract & Changes) CSA Reports Legend: CAPP - Computer-aided Process Planning BOM - Bill of Material SFC - Shop Floor Control NCM - Number Control Machine CA - Corrective Action CAD-E - Computer-aided Design Electrical CAD - Computer-aided Design PDM – Product Data Management Computer-aided Engineering CLS - Contractor Logistic Support Life Cycle Generic System Architecture Manufacturing BOM System As-built (Orders) NCM System CA System CAPP System SFC System (__________) (__________) (__________) (__________) As-planned (Planning) (__________) Part Test & Certification System Engineering Data Exchange Standards CAD & PDM System CSAR (__________) As-designed (Parts & BOM) CAD-E System (__________) As-designed (Electrical) Fielding CLS System (__________) CAE Schedule System (________) As-committed (Schedules) As-supported (Parts/Locations) Program Mgmt. System (________) As-authorized (Contract & Changes) CSA Reports Legend: CAPP - Computer-aided Process Planning BOM - Bill of Material SFC - Shop Floor Control NCM - Number Control Machine CA - Corrective Action CAD-E - Computer-aided Design Electrical CAD - Computer-aided Design PDM – Product Data Management Computer-aided Engineering CLS - Contractor Logistic Support Life Cycle Generic System Architecture Functional System(s) Architectures Manufacturing As-planned (Planning) CAPP System As-built (Orders) BOM System (__________) SFC System NCM System CA System (__________) (__________) (__________) (__________) Part Test & Certification System Engineering Fielding CAD & PDM System CSAR CLS System (__________) As-designed (Parts & BOM) CAE Schedule System CAD-E System (________) (__________) (__________) As-supported (Parts/Locations) Program Mgmt. System As-committed (Schedules) (________) As-authorized (Contract & Changes) As-designed (Electrical) CSA Reports System A Object -1 Identification: •ID#/Name,/Owner Attributes: •Size •Qty Relationships: •To-From •Up-Down •Other Objects System B System C Object -2 Object -2 Object -2 Identification: •ID#/Name,/Owner Attributes: •Size •Qty Relationships: •To-From •Up-Down •Other Objects Identification: •ID#/Name,/Owner Attributes: •Size •Qty Relationships: •To-From •Up-Down •Other Objects Identification: •ID#/Name,/Owner Attributes: •Size •Qty Relationships: •To-From •Up-Down •Other Objects Object -4 Identification: •ID#/Name,/Owner Attributes: •Size •Qty Relationships: •To-From •Up-Down •Other Objects Legend: CAPP - Computer-aided Process Planning BOM - Bill of Material SFC - Shop Floor Control NCM - Number Control Machine CA - Corrective Action CAD-E - Computer-aided Design Electrical CAD - Computer-aided Design PDM – Product Data Management Computer-aided Engineering CLS - Contractor Logistic Support Object -5 Identification: •ID#/Name,/Owner Attributes: •Size •Qty Relationships: •To-From •Up-Down •Other Objects Object -3 Object -1 Identification: •ID#/Name,/Owner Attributes: •Size •Qty Relationships: •To-From •Up-Down •Other Objects Identification: •ID#/Name,/Owner Attributes: •Size •Qty Relationships: •To-From •Up-Down •Other Objects Object -6 Object -4 Identification: •ID#/Name,/Owner Attributes: •Size •Qty Relationships: •To-From •Up-Down •Other Objects Identification: •ID#/Name,/Owner Attributes: •Size •Qty Relationships: •To-From •Up-Down •Other Objects Object -5 Identification: •ID#/Name,/Owner Attributes: •Size •Qty Relationships: •To-From •Up-Down •Other Objects Object -3 Object -1 Identification: •ID#/Name,/Owner Attributes: •Size •Qty Relationships: •To-From •Up-Down •Other Objects Identification: •ID#/Name,/Owner Attributes: •Size •Qty Relationships: •To-From •Up-Down •Other Objects Object -6 Object -4 Identification: •ID#/Name,/Owner Attributes: •Size •Qty Relationships: •To-From •Up-Down •Other Objects Identification: •ID#/Name,/Owner Attributes: •Size •Qty Relationships: •To-From •Up-Down •Other Objects Object -5 Identification: •ID#/Name,/Owner Attributes: •Size •Qty Relationships: •To-From •Up-Down •Other Objects System D Object -2 Object -3 Object -1 Identification: •ID#/Name,/Owner Attributes: •Size •Qty Relationships: •To-From •Up-Down •Other Objects Identification: •ID#/Name,/Owner Attributes: •Size •Qty Relationships: •To-From •Up-Down •Other Objects Object -6 Object -4 Identification: •ID#/Name,/Owner Attributes: •Size •Qty Relationships: •To-From •Up-Down •Other Objects Identification: •ID#/Name,/Owner Attributes: •Size •Qty Relationships: •To-From •Up-Down •Other Objects Identification: •ID#/Name,/Owner Attributes: •Size •Qty Relationships: •To-From •Up-Down •Other Objects Object -3 Identification: •ID#/Name,/Owner Attributes: •Size •Qty Relationships: •To-From •Up-Down •Other Objects Object -6 Object -5 Identification: •ID#/Name,/Owner Attributes: •Size •Qty Relationships: •To-From •Up-Down •Other Objects Identification: •ID#/Name,/Owner Attributes: •Size •Qty Relationships: •To-From •Up-Down •Other Objects Functional Environment (Program Management / Engineering / Manufacturing / Fielding) 13 Data Object Modeling Object -1 Identification: •ID#/Name,/Owner Attributes: •Size •Qty Relationships: •To-From •Up-Down •Other Objects Life Cycle Generic System Architecture Manufacturing As-planned (Planning) CAPP System As-built (Orders) BOM System (__________) (__________) SFC System NCM System CA System (__________) (__________) (__________) Part Test & Certification System Engineering Fielding CAD & PDM System CSAR CLS System (__________) As-designed (Parts & BOM) CAE Schedule System CAD-E System (________) (__________) As-designed (Electrical) As-committed (Schedules) (__________) As-supported (Parts/Locations) Program Mgmt. System (________) As-authorized (Contract & Changes) CSA Reports Legend: CAPP - Computer-aided Process Planning BOM - Bill of Material SFC - Shop Floor Control NCM - Number Control Machine CA - Corrective Action CAD-E - Computer-aided Design Electrical CAD - Computer-aided Design PDM – Product Data Management Computer-aided Engineering CLS - Contractor Logistic Support Objects: Location / Representation Media (format) Storage (located) Application (used by) Protocols (exchanged) Operating System Database (related) Meta-data (about) Characteristics, Attributes, & Features One to One One to Many Many to One Many to Many Drawings Documents •Specs/plans/orders Parts Software Changes (Effectivity) •Request/Orders/events Etc. 14 Life Cycle Generic System Architecture Manufacturing As-planned (Planning) CAPP System As-built (Orders) BOM System (__________) (__________) SFC System NCM System CA System (__________) (__________) (__________) Part Test & Certification System Engineering Fielding CAD & PDM System CSAR CLS System (__________) As-designed (Parts & BOM) CAD-E System (__________) As-designed (Electrical) CAE Schedule System (________) As-committed (Schedules) Data Object Modeling (__________) As-supported (Parts/Locations) Program Mgmt. System (________) As-authorized (Contract & Changes) CSA Reports Legend: CAPP - Computer-aided Process Planning BOM - Bill of Material SFC - Shop Floor Control NCM - Number Control Machine CA - Corrective Action CAD-E - Computer-aided Design Electrical CAD - Computer-aided Design PDM – Product Data Management Computer-aided Engineering CLS - Contractor Logistic Support Object -1 Identification: •ID#/Name,/Owner Attributes: •Size •Qty Relationships: •To-From •Up-Down •Other Objects Object -2 Identification: •ID#/Name,/Owner Attributes: •Size •Qty Relationships: •To-From •Up-Down •Other Objects Object -3 Identification: •ID#/Name,/Owner Attributes: •Size •Qty Relationships: •To-From •Up-Down •Other Objects Object -4 Object -6 Identification: •ID#/Name,/Owner Attributes: •Size •Qty Relationships: •To-From •Up-Down •Other Objects Identification: •ID#/Name,/Owner Attributes: •Size •Qty Relationships: •To-From •Up-Down •Other Objects Object -5 Identification: •ID#/Name,/Owner Attributes: •Size •Qty Relationships: •To-From •Up-Down •Other Objects 15 Life Cycle Generic System Architecture Manufacturing As-planned (Planning) CAPP System As-built (Orders) BOM System (__________) (__________) SFC System NCM System CA System (__________) (__________) Data Object Modeling (__________) Part Test & Certification System Engineering Fielding CAD & PDM System CSAR CLS System (__________) As-designed (Parts & BOM) CAD-E System (__________) As-designed (Electrical) CAE Schedule System (________) As-committed (Schedules) (__________) As-supported (Parts/Locations) Program Mgmt. System (________) As-authorized (Contract & Changes) CSA Reports Legend: CAPP - Computer-aided Process Planning BOM - Bill of Material SFC - Shop Floor Control NCM - Number Control Machine CA - Corrective Action CAD-E - Computer-aided Design Electrical CAD - Computer-aided Design PDM – Product Data Management Computer-aided Engineering CLS - Contractor Logistic Support Object -1 Identification: •ID#/Name,/Owner Attributes: •Size •Qty Relationships: •To-From •Up-Down •Other Objects Object -2 Identification: •ID#/Name,/Owner Attributes: •Size •Qty Relationships: •To-From •Up-Down •Other Objects Object -3 Identification: •ID#/Name,/Owner Attributes: •Size •Qty Relationships: •To-From •Up-Down •Other Objects Object -4 Object -6 Identification: •ID#/Name,/Owner Attributes: •Size •Qty Relationships: •To-From •Up-Down •Other Objects Identification: •ID#/Name,/Owner Attributes: •Size •Qty Relationships: •To-From •Up-Down •Other Objects Object -5 Identification: •ID#/Name,/Owner Attributes: •Size •Qty Relationships: •To-From •Up-Down •Other Objects 16 Life Cycle Generic System Architecture Manufacturing As-planned (Planning) CAPP System As-built (Orders) BOM System (__________) (__________) SFC System NCM System CA System (__________) (__________) (__________) Part Test & Certification System Engineering Fielding CAD & PDM System CSAR CLS System (__________) As-designed (Parts & BOM) CAE Schedule System CAD-E System (________) (__________) As-designed (Electrical) Data Object Modeling As-committed (Schedules) Export/Import (__________) As-supported (Parts/Locations) Program Mgmt. System (________) As-authorized (Contract & Changes) CSA Reports Legend: CAPP - Computer-aided Process Planning BOM - Bill of Material SFC - Shop Floor Control NCM - Number Control Machine CA - Corrective Action CAD-E - Computer-aided Design Electrical CAD - Computer-aided Design PDM – Product Data Management Computer-aided Engineering CLS - Contractor Logistic Support Object -1 Identification: •ID#/Name,/Owner Attributes: •Size •Qty Relationships: •To-From •Up-Down •Other Objects Object -2 Identification: •ID#/Name,/Owner Attributes: •Size •Qty Relationships: •To-From •Up-Down •Other Objects .XLS/.CVS Object -3 Identification: •ID#/Name,/Owner Attributes: •Size •Qty Relationships: •To-From •Up-Down •Other Objects Object -4 Object -6 Identification: •ID#/Name,/Owner Attributes: •Size •Qty Relationships: •To-From •Up-Down •Other Objects Identification: •ID#/Name,/Owner Attributes: •Size •Qty Relationships: •To-From •Up-Down •Other Objects Object -5 Identification: •ID#/Name,/Owner Attributes: •Size •Qty Relationships: •To-From •Up-Down •Other Objects Files XML Files Standards Files Direct Integrate 17 Data Mapping Strategies System A System B Export/Import Export/Import Object -2 Object -2 Object -1 Identification: •ID#/Name,/Owner Attributes: •Size •Qty Relationships: •To-From •Up-Down •Other Objects Identification: •ID#/Name,/Owner Attributes: •Size •Qty Relationships: •To-From •Up-Down •Other Objects .XLS/.CVS Files Verify/Certify Files Object -1 Identification: •ID#/Name,/Owner Attributes: •Size •Qty Relationships: •To-From •Up-Down •Other Objects Identification: •ID#/Name,/Owner Attributes: •Size •Qty Relationships: •To-From •Up-Down •Other Objects Object -6 Identification: •ID#/Name,/Owner Attributes: •Size •Qty Relationships: •To-From •Up-Down •Other Objects Identification: •ID#/Name,/Owner Attributes: •Size •Qty Relationships: •To-From •Up-Down •Other Objects Identification: •ID#/Name,/Owner Attributes: •Size •Qty Relationships: •To-From •Up-Down •Other Objects .XLS/.CVS Object -3 Object -4 Object -5 Mapping XML Files Standards Files Direct Integrate Mapping XML Files Verify/Certify Mapping Verify/Certify Mapping Verify/Certify Standards Files Direct Integrate Identification: •ID#/Name,/Owner Attributes: •Size •Qty Relationships: •To-From •Up-Down •Other Objects Object -4 Identification: •ID#/Name,/Owner Attributes: •Size •Qty Relationships: •To-From •Up-Down •Other Objects Object -3 Identification: •ID#/Name,/Owner Attributes: •Size •Qty Relationships: •To-From •Up-Down •Other Objects Object -6 Object -5 Identification: •ID#/Name,/Owner Attributes: •Size •Qty Relationships: •To-From •Up-Down •Other Objects Identification: •ID#/Name,/Owner Attributes: •Size •Qty Relationships: •To-From •Up-Down •Other Objects 18 Data Mapping Strategies System A Export/Import Mapping Object -2 Object -1 Identification: •ID#/Name,/Owner Attributes: •Size •Qty Relationships: •To-From •Up-Down •Other Objects Identification: •ID#/Name,/Owner Attributes: •Size •Qty Relationships: •To-From •Up-Down •Other Objects .XLS/.CVS Object -1 Identification: •ID#/Name,/Owner Attributes: •Size •Qty Relationships: •To-From •Up-Down •Other Objects Identification: •ID#/Name,/Owner Attributes: •Size •Qty Relationships: •To-From •Up-Down •Other Objects Files Files Identification: •ID#/Name,/Owner Attributes: •Size •Qty Relationships: •To-From •Up-Down •Other Objects Object -6 .XLS/.CVS Object -2 .XLS/.CVS Object -3 Identification: •ID#/Name,/Owner Attributes: •Size •Qty Relationships: •To-From •Up-Down •Other Objects Identification: •ID#/Name,/Owner Attributes: •Size •Qty Relationships: •To-From •Up-Down •Other Objects Verify/Certify Files Object -4 Object -5 System B Export/Import Mapping XML Files Verify/Certify Standards Files Verify/Certify Direct Integrate XML Files Mapping Mapping Verify/Certify XML Files Standards Files Direct Integrate Standards Files Identification: •ID#/Name,/Owner Attributes: •Size •Qty Relationships: •To-From •Up-Down •Other Objects Object -4 Identification: •ID#/Name,/Owner Attributes: •Size •Qty Relationships: •To-From •Up-Down •Other Objects Object -3 Identification: •ID#/Name,/Owner Attributes: •Size •Qty Relationships: •To-From •Up-Down •Other Objects Object -6 Object -5 Identification: •ID#/Name,/Owner Attributes: •Size •Qty Relationships: •To-From •Up-Down •Other Objects Identification: •ID#/Name,/Owner Attributes: •Size •Qty Relationships: •To-From •Up-Down •Other Objects Direct Integrate 19 Data Mapping Strategies System A Export/Import Mapping Object -2 Object -1 Identification: •ID#/Name,/Owner Attributes: •Size •Qty Relationships: •To-From •Up-Down •Other Objects Identification: •ID#/Name,/Owner Attributes: •Size •Qty Relationships: •To-From •Up-Down •Other Objects .XLS/.CVS Files Identification: •ID#/Name,/Owner Attributes: •Size •Qty Relationships: •To-From •Up-Down •Other Objects Identification: •ID#/Name,/Owner Attributes: •Size •Qty Relationships: •To-From •Up-Down •Other Objects Files Costs Files Object -1 Object -6 .XLS/.CVS Object -2 .XLS/.CVS Identification: •ID#/Name,/Owner Attributes: •Size •Qty Relationships: •To-From •Up-Down •Other Objects Identification: •ID#/Name,/Owner Attributes: •Size •Qty Relationships: •To-From •Up-Down •Other Objects Identification: •ID#/Name,/Owner Attributes: •Size •Qty Relationships: •To-From •Up-Down •Other Objects Verify/Certify Object -3 Object -4 Object -5 System B Export/Import Mapping XML Files Verify/Certify Standards Files Verify/Certify XML Files Identification: •ID#/Name,/Owner Attributes: •Size •Qty Relationships: •To-From •Up-Down •Other Objects Object -3 Identification: •ID#/Name,/Owner Attributes: •Size •Qty Relationships: •To-From •Up-Down •Other Objects Mapping Direct Integrate Mapping Verify/Certify Standards Files Direct Integrate XML Files Standards Files Costs Costs Object -4 Identification: •ID#/Name,/Owner Attributes: •Size •Qty Relationships: •To-From •Up-Down •Other Objects Object -6 Object -5 Identification: •ID#/Name,/Owner Attributes: •Size •Qty Relationships: •To-From •Up-Down •Other Objects Identification: •ID#/Name,/Owner Attributes: •Size •Qty Relationships: •To-From •Up-Down •Other Objects Direct Integrate Costs 20 Basic Configuration Verification System Concept GEIA 836 STEP GEIA AP 232 836 AsAuthorized AsCommitted AsDesigned AsPlanned AsBuilt AsSupported Authorize Data Schedule Data Design Data Plan Data Build Data Support Data InSync InSync®: A CM/PDM Functional Architecture Business Management CI Audits Contracts Baseline Bills of Material BOM Identification Parts Documents Change Control As-Designed As-Built As-Planned As-Maintained CR Software Drawings CP CO Control Accounting Integrated Workflow Vault/Launch Authorized Baseline Baseline Compares Comparison Reports Scheduled Baseline Baseline Compares Ad Hoc Export/Import ITK Security Design Baseline Planned Baseline Built Baseline Supported Baseline Baseline Compares Baseline Compares Baseline Compares Baseline Compares Comparison Reports Comparison Reports Comparison Reports Comparison Reports 21 ISS Use of Standards In Life Cycle Supportability Engineering Data: Drawing, Model, Metrics… STEP AP 203 / 232 / pdm schema Design Data/Structure 90021 ERP Data Product Structure Data, Specs and Parameters 165443 ‘ 165837 ‘ STEP AP 232*, pdm schema Supportability Analysis IN-SERVICE/ SUPPORT LSAR/ LMI ASD 2000M 1388-2B, 00-60 Tech Pub/ IETM Data IPB / IPC/ IPL Data and Graphics Delivered Data/Structure Serialized Part Data: Maintenance In-Service Data/Structure Initial Product/ Support Definition Two-Way collaboration, reconciliation, coordination MANUFACTURING/ PRODUCTION DESIGN ENGINEERING (STEP AP 239) One-Two -Way Data Flow Asset Management Spares Ordering, Inventory Mgmt, Obsolescence Planning, … 165443 ‘ 165837 ‘ ‘ Training Data STEP AP 232*: Not used in conjunction with Life Cycle Supportability, today, The Mechanisms & Processes (Basic Configuration Reconciliation Process) As-Designed As-Planned As-Built Parts Defined Parts Planned Parts Ordered (Dwgs/PLs) (IP Plans) (Fab. Orders) End Item 1 Assembly, PN 1 Sub Assy., PN 1 Component, PN 2 Component, PN 3 Component, PN 2 Sub Assy., PN 1 Component, PN 2 Component, PN 3 Component, PN 2 Assembly, PN 1 Sub Assy., PN 1 Component, PN 2 Component, PN 3 Component, PN 2 Sub Assy., PN 1 Component, PN 2 Component, PN 3 Component, PN As-Designed Baseline BOM for Parts & Assemblies IP Plan/Fab Plans 1 Assembly, PN Fab . Orders 1 Assembly, PN 1 Sub Assy., PN 1 Component, PN 2 Component, PN 3 Component, PN 1 Sub Assy., PN 1 Component, PN 2 Component, PN 3 Component, PN 2 Sub Assy., PN 1 Component, PN 2 Component, PN 3 Component, PN IP Plan/Fab Plans 2 Assembly, PN 1 Sub Assy., PN 1 Component, PN 2 Component, PN 3 Component, PN 2 Sub Assy., PN 1 Component, PN 2 Component, PN 3 Component, PN Manufacturing Planning for Parts & Assemblies 2 Sub Assy., PN 1 Component, PN 2 Component, PN 3 Component, PN Fab. Orders 2 Assembly, PN 1 Sub Assy., PN 1 Component, PN 2 Component, PN 3 Component, PN 2 Sub Assy., PN 1 Component, PN 2 Component, PN 3 Component, PN Fabrication Orders for Parts & Assemblies 23 Validation & Verification Cycle (Configuration Verification Action Items) CVAI: Life Cycle Generic System Architecture Configuration Verification Action Item Manufacturing As-planned (Planning) As-built (Orders) BOM System (__________) CAPP System SFC System (__________) (__________) NCM System CA System (__________) (__________) Part Test & Certification System Engineering Fielding CSA CAD & PDM System (InSync) CLS System (__________) As-designed (Parts & BOM) CAE Schedule System CAD-E System (________) (__________) As-designed (Electrical) As-committed (Schedules) Plans Orders (__________) As-supported (Parts/Locations) Program Mgmt. System (________) As-authorized (Contract & Changes) CSA Reports Legend: CAPP - Computer-aided Process Planning BOM - Bill of Material SFC - Shop Floor Control NCM - Number Control Machine CA - Corrective Action CAD-E - Computer-aided Design Electrical CAD - Computer-aided Design PDM – Product Data Management Computer-aided Engineering CLS - Contractor Logistic Support Parts List Final Reconciled Reports CVAI: Configuration Verification Action Item 24 Product’s Life Cycle Management (Basic Confirmation Process) As-Authorized (_________) As-Committed (_________) As-Designed (_________) As-Planned (_________) Engineering Design (Perform engineering design) In Work Completed Approved Released Commitment Scheduling (Commitment to schedule) In Work Completed Approved Released Authoring Engineering (Authorizing parts design) In Work Completed Approved Released CSA Reports 1 2 4 5 3 DD 250 Reporting Audit Trail Was the installation right? Was the purchase right? Was the fabrication right? Was the design right? Was the commitment right? Was the authorization right? As-Built (_________) Installation Plan (IP) (Planning for final assembly) In Work Completed Approved Inspected Delivered Make Parts – Fabrication/Assembly (Planning for Fabrication/Assembly) In Work Completed Approved Inspected Stocked to Inventory Buy Parts - Purchase (Planning for Buy) Purchase Request Purchase Order Received Inspected Stocked to Inventory All’s Right Not Right Waivers Deviations 25 DD Form 250 Product’s Life Cycle Management (Basic Reconciliation Process) As-Authorized As-Committed (_________) (_________) As-Designed (_________) As-Planned (_________) As-Built (_________) As-Maintained (_________) As-Disposed (_________) Marketing Contracts EBOM Structure MBOM Structure OBOM Structure RBOM Structure DBOM Structure Engineering Material Catalog Processes Manufacturing Material Catalog Processes Routings Resources Tooling Operational Processes Routings Resources Tooling Serial Number Lot Code QA/MRB Service Records Retrofit Processes Routings Resources Tooling Serial Number Lot Code QA/MRB As-Built History Repair/Refurbish Records Disposed Processes Resources Serial Number Lot Code As-Was/Is History Storage, Salvage Disposal Records Recycling WBS Budgets Sales Orders Computer-Aided Engineering Engineering Release Configuration Reconciliation (InSync) DD250 26 STEP Data Exchange (The Back Story – SI/BCA) Enterprise Supplier 27 Type Design Data/Process Flow Type Design Data PDM Output STEP Files PS Files PKG Files ERP or other Systems Other Files * InSync/SI Processing Translated Files * Interface / Integration with other data systems may be implemented as a “push or pull” transaction process or as a “web service.” Vista Reporting Imported Files InSync Generated XML* Files Formatted PDF* Files InSync Screens OS Vaults - Reports (XML, PDF) - STP - PS - PKG Browser View - “Generated XML” - “Formatted PDF” - Formatted HTML - Multi-Level - XML File Compare Non-Vaulted “Work” 28 ISS’s Integrated Support System Supplier Integration (SI/BCA) Enterprise Engineering / Procurement Data Collection and Outsourcing System Product Information (PDM System) Supplier www Supplier Integration Software View Product Unzip and/or Information, Email Notification decrypt TDP and related files of TDP Ready Content Collection Supplier PDM System PDM Database Vault FTP/HTTP Geometry Geometry Documents •Generate STEP File •Zip and/or encrypt TDP Email Notification of TDP Received TDP Archive Documents 29 As-Authorized (ECCM) Product’s Life Cycle Management Cost Estimating Capacity Planning & Assessment Specifications As-Committed (DM2000) (Boeing MMA P-8A) Master Schedule Work Breakdown Structure Budgets Sales Orders Cost Accounts Effectivity As-Designed (DCAC) Baseline Release Document Control Product Definition EBOM Bill of Routings Effectivity (Eng.) MBOM Effectivity (Manf.) Bill of Routings/Resources Master Production Schedule Proposed Capacity Planning MRP/CRP/Procurement Work Order Release As-Planned (MES) As-Built (MES) As-Tested (ALRMS) As-Delivered (InSync) Receiving/Inspection Receiving Instructions Dock-to-Stock Inventory (WIP) Lot Code / Serial Numbering Shop Floor Control Labor Collection Work Measurements Process Instructions Test Procedures Test Results Part and System Restrictions CM Status Accounting As-Built Snapshot CM Reconciliation CM Status Accounting Lot Code / Serial Numbering Deviations / Waivers As-Maintained (OOMA) Field Return / Retrofit Field Service CM Reconciliation Lot Code / Serial No. CM Status Accounting As-Built History As-Disposed (????) Storage, Salvage To-Become (Recycle) CM Reconciliation Lot Code / Serial No. CM Status Accounting As-Was/Is History 30 Product’s Life Cycle Management (Boeing MMA P-8A Reconciliation Process) As-Authorized As-Committed (ECCM) (DM2000) As-Designed (DCAC) As-Planned (MES) As-Built (MES) As-Maintained (OOMA) As-Disposed (????) Marketing Contracts EBOM Structure MBOM Structure OBOM Structure RBOM Structure DBOM Structure Engineering Material Catalog Processes Manufacturing Material Catalog Processes Routings Resources Tooling Operational Processes Routings Resources Tooling Serial Number Lot Code QA/MRB Service Records Retrofit Processes Routings Resources Tooling Serial Number Lot Code QA/MRB As-Built History Repair/Refurbish Records Disposed Processes Resources Serial Number Lot Code As-Was/Is History Storage, Salvage Disposal Records Recycling WBS Budgets Sales Orders Computer-Aided Engineering Engineering Release Configuration Reconciliation (InSync) 31 Life Cycle Baseline Reconciliation A System Overview and Description of the Basic Configuration Verification System (BCVS) Questions & Comments ACDM 15th Annual Technical Conference 21-22 March 2010 Ram White, Integrated Support Systems, Inc. 32 Life Cycle Baseline Reconciliation A System Overview and Description of the Basic Configuration Verification System (BCVS) ACDM 15th Annual Technical Conference 21-22 March 2010 Ram White, Integrated Support Systems, Inc. 33