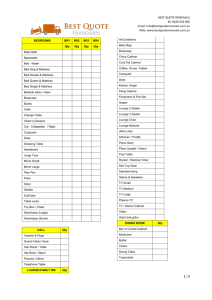

Resources

advertisement

RCA Discussion: RCA’s Focus on Resources Larry R. White, CMA, CFM, CPA, CGFM Executive Director, Resource Consumption Accounting Institute 1 What Causes Costs? Resources (also creates any revenues!) 2 Simple Process Resource Pool Proportional OUTPUT Fixed Organizational Element (Support or Production) Material/Commodity Labor Equipment Operating Budget Another Resource Pool (s) Or Final Product/Service Material Services (Reflecting Resources Applied) Resource Quantities Drive Monetary Quantities 3 More Realistic Resource Flows Resource Pool A Resource Pool E Resource Pool B Final Output 1 Final Output 2 Resource Pool F Final Output 3 Resource Pool C Resource Pool G Final Output 4 Resource Pool D Resource Pool H 4 What Are the Primary Characteristics of Resources? • Capability – Quality or Qualitative Characteristics • Capacity – Quantity They Provide • Consumption/Cost – Consumption/Cost Structure – Consumption/Cost Behavior 5 How Do We Define Capacity? • Productive • Non-Productive • Idle/Excess Questions: • Who is Responsible for Idle & Excess Capacity? • What can Allocations of Idle & Excess Capacity Do to Costs? 6 Connects Operations & Finance Operational View Financial View Resource/Resource Pools Intermediate Outputs Processes/Value Streams Products/Services Real Time Action Oriented Internally Focused FR Time Report Oriented Externally Focused Resource Consumption Accounting Pillar 1: Focus on Resources & their Consumption Understand your Resources & Their Consumption….Understand Cost Provides a Framework for Capacity Management Pillar 2: Quantity Structure for Resource Consumption Operational Quantities Drive Costs Model the Operation & Use of Resources….then Apply Cost Enables Resource Capacity Management Demonstrates Causality of Value Chain Relationships Pillar 3: Recognizing the Inherent and Changing Nature of Costs Resource Pools Start with an Inherent Cost Structure As Resources are Consumed, the Nature of their Costs Change Costs that are Initially Proportional by Nature can Change from Proportional to Fixed Based on Consumption Patterns Allows Value Chain Modeling of Resource Cost Responsiveness 8 Resource Consumption Accounting • RCA Inherits Core Principles from German Cost Management (GPK) – GPK is a Well Developed Standard Costing System – Principles Applied in Practice since the Late 1940’s – Principles Implemented by 3,000+ Companies Capacity Analysis and Management Process Analysis and Management RCA • RCA Integrates – Activity-based Costing and Throughput Concepts • RCA Creates an Integrated Economic Model of Operations for Decision Making – Enterprise Optimization – Principle Based – Superior Marginal Analytics Resource view Advantages GPK CapacityFocused Process view Advantages ABC ActivityFocused 9 www.RCAInstitute.org lwhite@rcainstitute.org 757 288 6082 10 RCA and Interrelationships - Quantity Consumption with Values - Resource Interrelationships - Activities Consumed by the Resources that the Services are Provided for - Activities Consumed by a Cost Objects 4/13/2015 7:05 AM © RCA Institute 2010 11 RCA Storyboard S: Ancillary Production Equipment RP: Dryer (Hours) Capacity: 100 Output Qty: 100 S: Plant Engineering and Maintenance RP: Chiller (Hours) Capacity: 50,000 Output Qty: 50,000 RP: Plant Maintenance (Maint. Labor) Capacity: 30,000 Output Qty: 30,000 S: Administration Human Resources & Accounting Perfor m RP: Admin Labor (Labor hours) Capacity: 17,000 Output Qty: 17,000 HR Legend Perfor m S-Support Accou nting P- Production Perfor m P: Extrusion Line Department S: Quality Assurance Admin Resource Pool Abbreviated RP RP: Extrusion Labor (Labor hours) Capacity; 32,000 Output Qty: 30,000 RP: Extrusion Machine1 (Machine hours) Capacity; 17,520 Output Qty: 10,000 RP: QA Labor (Labor hours) Capacity: 14,000 Output Qty: 14,000 QA Testin g Activ ity Produ ct Retur ns Manufacturing Costs Product Support Cost Budgeted Products Product P & L’s Common Fixed Costs 12 RCA Information Plant Maintenance Resource Pool Output Measure: Maintenance Labor Hour Output Quantity: 20,000 Hours Primary Costs Fixed Proportional Technician Wages $ - $ 600,000 Supervisor Salary $ 80,000 $ General Material $ 12,000 $ Depreciation: Shop Equipment $ 50,000 $ $ 142,000 $ 700,000 $ 6,000 $ 24,000 $ $ 1,100 500 $ $ 10,000 $ 7,600 $ 34,000 $ 149,600 $ 734,000 100,000 - Secondary Costs Resource Pool Output Utilities MW-Hrs Activity/Process Driver HR: Benefits Adjustments Purchase: Gen Materials # Adjusts # PO's Fixed Qty Prop Qty 40 160 Fixed Qty Prop Qty 22 10 0 200 Total Resource Pool Costs Unit Cost Rates (/20,000 Hrs) 7.48 36.70 13