"Skill Charts` Compilation" (WP 2)

advertisement

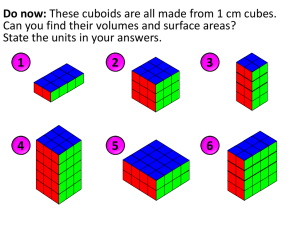

NOMET II IN Integrated human resources development and monitoring system for adding innovation capacity of labour force and entrepreneurs of the metal engineering, machinery and apparatus sector SKILL CHARTS’ COMPILATION Dr. Jüri Riives Human Resources (HM) In most industries, it is now possible to buy on the international marketplace machinery and equipment that is comparable to that in place at the leading global firms. Access to machinery and equipment is not the differentiating factor. Ability to use it effectively is. A company that lost all of its equipment but kept the skills and know-how of its workforce could be back in business relatively quickly. A company that losts its workforce, while keeping its equipment, would never recover. / Robert McLean, Performance Measures in the New Economy (The Premier's Council of Ontario, Ontario, Canada, 1995)/ Financial Return of capital employed Customer loyality Customer On-time delivery Internal/business processes Learning and growth /Robert S. Kaplan, David P. Norton/ Process quality Process cycle time Employee skills and knowledge HR and Strategy Implementation HR Strategic Management Balanced Performance Measurement Employee Strategic Focus Strategy Implementation Company Performance Knowledge Management System Which strategic goals / objectives / outcomes are critical? What are performance drivers for each goal? How would we measure progress towards those goals? What are the barriers to the achievement for each goal? Is the HR function providing the company with the employee competencies and behaviours necessary to achieve these objectives? What needs to change? Goals, objectives People Culture Structure Processes The culture of an organisation can be defined as a set of everyday values, beliefs, principles, attitudes of the people in an organisation. Skill chart composition Description of the list of skills and knowledge Country level Skill chart List of skills and knowledge Neede level Existing level Professional standards Profession Company level Process Structure Business chain & Key processes 1 Marketing 2 3 4 R&D Process Planning Purchasing D epartm ents B oard F inanc e Innovation M ark eting P urc has ing P roduc tion Q uality Logis tic s S elling S ervic ing 1 2 3 6 5 Production P roc es s es 4 5 7 Logistics 6 Selling 7 8 8 Servicing Two approaches Criteria-centered approach Flexibility Innovativity Profitability Service Output of skill charts Productivity Customerbased approach Quality Manufacturing cost Person-centered approach Teamwork Manpower development Feedback Motivation of empoyees Staff evaluation objectives Specification of need for training Brainstorming Improvement of labor efiiicienty Obtaining goals Skill chart Estimation of existing level EVALUATION Skill chart List of skills and knowledge Needed level Existing level 5 3 During the evaluation a guess value will be assigned onto management of the organisation and its departments, and in another hand onto work places and performance of the people working there. During job evaluation will be estimated its complexity, specifity and relevance to organisation in terms of its objectives and task performing. At evaluation of staff members will be estimated their performance appraisal, enabling to find correlation in terms of specific norms at completing tasks. Assessment chain (from target to appraisal) Established general targets Productivity => Quality => Established specific targets To manufacture 20 shafts/h Criteria covering specific targets General knowledge of industrial 0% of defective engineering products Machining Max 2% of total knowledge quantity are Knowledge of reworked operational defective technology products Evaluation in terms of skills and knowledge Evaluation Based on communicated information Based on work performanceon Staff member to be evaluated 1 Immediate boss Colleague Selfassessment 2 Personnel manager 3 External audit Examination Skill chart composition Estimations of needed level General skills Work safety rules Language skills D L Basic skills Knowledge of materials Skills of reading technical drawings Skills of use lifting equipment Staff member to be evaluated IT IT d Ra l I Skill chart Area of competence Needed level l II Specific skills Knowledge of selection inserts Knowledge of manufacturing technology Skills of measurement technology Existing level I 3 3 II 3 3 3 3 4 4 2 3 4 5 3 4 5 2 4 3 2 3 3 2 3 3 Marketing Situation description Marketing is not existing or it is existing very passive Active marketing. Exist marketing objectices for different products and regions Exists marketing strategy and/or marketing policies 1-2 3-4 5 Purchasing Situation description Experience-based purchase 1 Random purchase 2 1-2 Small nomenclature of materials 3-4 Average nomenclature of materials 5 Large nomenclature of materials 1-2 No subcontracting 3-4 Average subcontracting 5 Amount of subcontracting is significant 4 1-2 Semimanufactured articles are not purchased 3-4 Purchase of semimanufactured articles is average 5 Purchase of semimanufactured articles is significant 5 1-2 Supply chain is not optimised 3-4 Inventories are minimised 5 JIT (Just-In-Time) Management 1-2 3-4 5 3 Purchase according approved database register Product Development (PD) Situation description Inactive PD 1 Missing PD 2 1-2 PAD 3-4 2D and 2.5D CAD 5 3D CAD, FEM 3 1-2 Simple products 3-4 Products of average complexity 5 Sophisticated products 4 5 Professional PD 1-2 3-4 5 Not based on Average conventional Complicated engineering calculations engineering calculations engineering calculations 1-2 No dimension chain calculations 3-4 Dimension chain calculations are used randomly 5 Dimension chain calculations are significant 1-2 3-4 5 Production Planning Situation description 1 1-2 1-2 2 1-2 1-2 3 >50 1-2 4 >4 1-2 5 >10 1-2 6 1-2 1-2 7 Not at all 1-2 Number of main production processes 2-5 3-4 Number of manufacturing departments 2-5 3-4 Number of workers 51-150 3-4 Number of manufacturing technologies 4-8 3-4 Number of different products per year 11-50 3-4 Annual turnover (mill.EUR) 3-4 3-4 Use of ERP Random 3-4 Over 5 5 Over 5 5 Over 150 5 Over 8 5 Over 50 5 Over 5 5 Systematic 5 Production Situation description Batch production 1 Mass production Customised tailor-made production 2 1-2 Automated machine tools 3-4 CNC 5 Conventional machine tools 3 1-2 Simple products 3-4 Products of average complexity 5 Sophisticated products 4 1-2 Nonprecision products 3-4 Precision products 5 High-precision products 1-2 3-4 5