File

advertisement

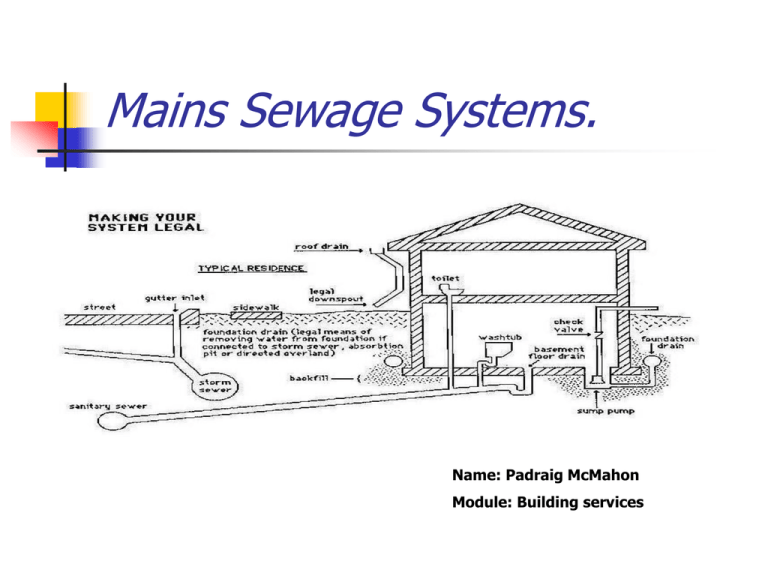

Mains Sewage Systems. Name: Padraig McMahon Module: Building services Definitions. Surface water Run-off of rain water from roofs and any paved surfaces around the building. Soil water Water containing excreted material i.e from W.C. pans Waste water Used water from waste appliances i.e sink, bath etc. This includes washing machines and dish washers. Foul water Any water contaminated by soil water or waste water Definitions. Ventilation To prevent the water seal from being broken by pressures or suction and to allow the release of gases Sewage Mixture of foul and surface water which needs to be removed from the building Sewer Form of drain which collects foul water/sewage from a number of drains. Definitions. Traps All points of discharge into a drainage system should be fitted with a water seal to prevent foul air leaking into the building all traps not part of a removable appliance should be removable or fitted with a cleaning eye. Drain A below ground pipe or closed channel where water flows by gravity Sewerage A network of sewers that disposes of sewage from a community, town or city. Effluent/sewage disposal. Domestic sewage consists of human wastes, paper and vegetable matter. This is organic waste because it is made of compounds of carbon and can be broken down by micro organisms. Sewerage is a system of under ground pipes used to collect and carry sewage either to a treatment unit i.e. septic tank or a a public/ main sewer. The concept of sewage is to pipe waste mater both solid and liquid away from the building, to allow for safe treatment and return to the water table. Types of Waste disposal. Main types of waste disposal There are two main types of waste disposal available in Ireland, septic tanks and sewage systems which under EU law must now incorporate a treatment works. Septic tanks Septic tanks are mainly used in one off housing in rural areas. this is the typical system used in the country side. Sewerage Sewage systems are used mainly in built up areas such as villages, towns and cities and is necessary to have a large number of houses to make such a system viable. Public Drainage Schemes. Types of drainage systems. There are 2 main types of Public drainage schemes, separate drainage system or combined drainage system. Separate drainage system. Surface water is kept separate from foul water by means of two separate pipe lines. Surface water remains clean and needs no treatment. Higher cost to install but cheaper to run as their is less material entering the treatment works. Combined drainage system Foul and surface water are mixed and the system uses one large pipe. their is a danger especially with heavy rain fall the treatment plant can get over loaded, plus the previously clean water needs to be cleaned again at extra cost. Sewage treatment Plants. Typical Treatment Processes. The following are the typical processes involved in sewage treatment. Preliminary treatment (1) This is done to remove large solids and grit to prevent blockages further down the line. A system of sedimentation, mesh filters or equipment such as vortex separators can be used to do this. Primary treatment (2) This uses a system of sedimentation tanks, were the water is stagnant enough to allow fine sediments to fall out of suspension by gravity. Treatment Processes. Other materials such as oil and grease can form a scum on the surface of the water and this can be scraped off. These forms of treatment the bod measurement by up to 40% and suspended solids by 70%. Secondary treatment This involves exposing the settled sewage to bio chemical reactions under aerobic conditions. Purified water is then moved to secondary settlement tanks. The most common methods used for this are biological filtration and activated sludge. Treatment Processes. Biological filtration the waste water is trickled through a bed of inert material on which a bio mass of micro organisms develops and aeration occurs naturally. Activated Sludge Mechanical agitators are used to aerate the mixture and to encourage the growth of new biomass. In both cases the bacteria created are able to grow multiply and purify the sewage, and are later removed in sediment tanks. Treatment Processes. Tertiary treatment This third stage is used if the effluent has still not reached a suitable quality. Their are three main methods used to resolve this 1. Lagoon settlement 2. Irrigation on to land 3. Filtration using sand or gravel. Sludge treatment Sludge has two main components, liquid effluent and sludge solids. Effluent is easily treated but the sludge can cost up to 50% of overall costs to dispose of. It can be incinerated, spread on the land or placed in land fill. Natural Rain Water cycle. The natural rain water cycle will also further purify the water and remove any remaining waste material. Pipe Laying and Connections to Sewer Lines. Typical aboveground System. This is an example of above ground typical drainage pipes showing waste and foul water pipes. Note the vent and the gradient on the pipes. These are all linked to the sewer system. Underground Pipe Work. Layout 1) The lay out should be kept a s simple as possible with changes in gradient and direction kept to a minimum. 2) Access should be provided only were necessary and connections should always be made obliquely to the direction of the flow. 3) The system should be ventilated by a flow of air and should be at the end of each main drain and to any branch longer than 6 meters Underground Pipe Work. 4) Pipes should be laid at an even gradient and any change in this should have an access point. 5) Pipes should be laid in a straight line and were small bends occur access should be provided 6) When laying pipes near or under building and in unstable ground special considerations should be made to allow for settlement 7)pipes should be bedded in sand, clay or cement were appropriate. Simple pipe Layout. Two simple systems showing combined and separate systems Combined sewers Separate sewers Pipe Laying. This diagram shows how sight rails in conjunction with a boning rod are used to insure an even gradient while laying out the trenches. Bedding for Rigid Pipes. Bedding for rigid Pipes. key Small stones, sand and clay. 10 mm Aggregate with a compaction factor of 0.2. •This must be well compacted and this type of bedding is necessary when connecting to a mains sewer as it is a rigid pipe. Bedding of Flexible Pipes. Bedding for flexible piping key Small stones sand and clay. Granular fill. 10 mm aggregate with a compaction faction of 0.2 •This type of fill is used mostly around foul water pipes and general drainage. General Pipe Materials. The following are the main types of pipes used in underground gravity feed systems Rigid pipes Fibber cement Vitrified clay Concrete Flexible pipes uPVC uPVC is the most commonly used as it comes in a wide variety of shapes is easily joined and cut and has a wide variety of fittings. Jointing of Pipes. All joints should be appropriate to the material being used. To minimise the effects of differential settlement pipes should have flexible joints and be allowed room for movement were ever possible All joints should remain sealed under test conditions and normal working conditions and their working life. Nothing in the pipes, their fittings e.t.c should obstruct the flow of materials and all joints should run obliquely to the direction of flow. Joining to a Mains Sewer. Note the shape of the saddle. The main sewer is cut to allow the round sleeve to inter and it is then bedded in mortar to insure a good seal. Samples of available Fittings. Samples of Piping. Plain gulley Waste water reducer External gulley Tapered joint with flexible hosing Samples of Piping. Connection to a Toilet. Note the Allowance for settlement around the pipe Man hole junction. Note the cut section pipes. This hole will have a concrete base uPVC junction box. Quick and easy to Install and will be sat on a concrete base Samples of Man Holes. Precast man hole with cut section Pipes. Close up of a similar precast man hole with flexible pipes. Precast man hole used to change gradients. Jointing methods Available. Joining of Piping. Piping must be jointed securely but still allow for flexibility and settlement. Pipe work should be tested before it is back filled, using either smoke, water or air under pressure. Pipe should be knocked together using waste timber to insure no damage to the edges. Different joints are used in different situations but uPVC is the most common, using simple sleeve joints or rubber seals. Pipe jointing. This is an example of a pipe joining to another pipe. Note the way the branched section is running obliquely to the other pipe to insure the continued flow of waste material. Types of Joints. Access Junctions and Man Holes. Clearance of Blockages. There are four main types of access to remove blockages. Roding eyes These provide access to any pipe in accessible from the trap. Access fittings Small chambers on the pipe but do not have an open chamber. Inspection chambers shallow chambers which allow access for working at ground level. Manholes Large chambers with working space at drain level. All covers should be easy to remove and of a suitable strength. They should be air tight were necessary and secure in position. Regulations on Access fittings. Access fittings Depth to invert. 0.6 A.J 0.6 Internal size length & width 150 x 100 300 x 100 300 x300 Shaft 2.7 900 x 840 Man hole 2.7 1200X750 1200 x 840 Inspection chamber 1.0 450 x 450 Connection. Connecting to Main Sewers. When connecting to a mains sewer one must make the necessary applications when applying for planning permission in individual cases. In housing estates the builder is responsible for making the necessary connection. In both cases their is a fee, which varies from county to county and permission must be sought before digging for a sewer and the necessary research should be carried out in relation to under ground wires e.t.c. The end