Class 2b

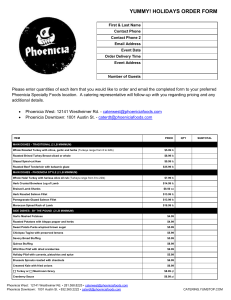

advertisement

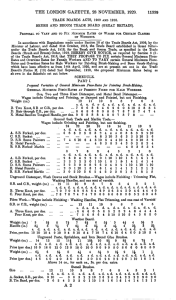

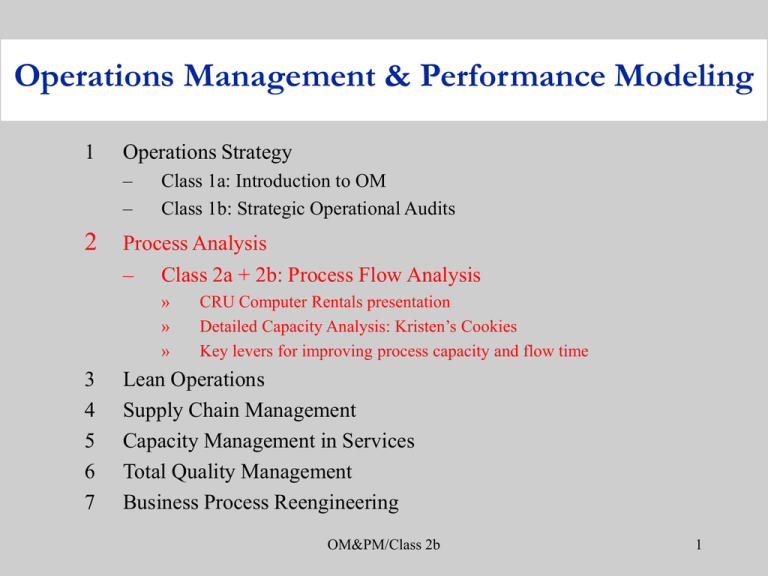

Operations Management & Performance Modeling 1 Operations Strategy – – Class 1a: Introduction to OM Class 1b: Strategic Operational Audits 2 Process Analysis – Class 2a + 2b: Process Flow Analysis » » » 3 4 5 6 7 CRU Computer Rentals presentation Detailed Capacity Analysis: Kristen’s Cookies Key levers for improving process capacity and flow time Lean Operations Supply Chain Management Capacity Management in Services Total Quality Management Business Process Reengineering OM&PM/Class 2b 1 CRU Computer Rentals: Revenue and Cost Drivers Status 40 Ship Receiving 30% Repairs 70% R Status 24 Customer Ic 15% Status 41 Pre-Config R2 R1 Parts places order Receives from Supplier Status 32 Ship Config Repairs Status 20 OM&PM/Class 2b Status 42 2 Kristen’s Cookies: Flow Chart Take Order Order Ready Wash & Mix Spoon Load & Set Timer You You Roommate, Oven 6min / 1-3doz 2min / doz 1 min / doz Pay Pack Cool Unload Roommate 1 min / order Roommate 2 min /doz --- Roommate OM&PM/Class 2b Bake Oven 9 min/doz 5 min 3 Process Architecture is defined and represented by a process flow chart: Process = network of activities performed by resources 1. Process Boundaries: – input – output 2. Flow unit: the unit of analysis 3. Network of Activities & Storage/Buffers – activities with activity times – routes: precedence relationships (solid lines) 4. Resources & Allocation 5. Information Structure & flow (dashed lines) OM&PM/Class 2b 4 Operational Measure: Flow Time Driver: Activity Times (Theoretical) Flow Time Critical Activity Flow Time efficiency OM&PM/Class 2b 5 Levers for Reducing Flow Time Decrease the work content of critical activities – work smarter – work faster – do it right the first time – change product mix Move work content from critical to non-critical activities – to non-critical path or to ``outer loop’’ Reduce waiting time. OM&PM/Class 2b 6 Most time inefficiency comes from waiting: E.g.: Flow Times in White Collar Processes Industry Process Average Flow Time Theoretical Flow Time Flow Time Efficiency Life Insurance New Policy Application 72 hrs. 7 min. 0.16% Consumer Packaging New Graphic Design 18 days 2 hrs. 0.14% Commercial Bank Consumer Loan 24 hrs. 34 min. 2.36% Hospital Patient Billing 10 days 3 hrs. 3.75% Automobile Manufacture Financial Closing 11 days 5 hrs 5.60% OM&PM/Class 2b 7 Operational Measure: Capacity Drivers: Resource Loads (Theoretical) Capacity of a Resource Bottleneck Resource (Theoretical) Capacity of the Process Capacity Utilization of a Resource/Process = throughput [units/hr] capacity [units/hr] OM&PM/Class 2b 8 A Recipe for Capacity Measurements Resource Unit Load Resource Capacity (time/job) Unit Capacity # of units Total Process Resource Capacity Utilization* * assuming system is processing at full capacity OM&PM/Class 2b 9 Cost Capacity Profile Demand Capacity [units/time] Process Capacity Resource x NCX-10 Furnaces OM&PM/Class 2b Marginal Investment Cost [$/unit/time] 10 Levers for Increasing Process Capacity Decrease the work content of bottleneck activities – – – – work smarter work faster do it right the first time change product mix Move work content from bottlenecks to non-bottlenecks – to non-critical resource or to third party Increase Net Availability – – – – work longer increase scale (invest) increase size of load batches eliminate availability waste OM&PM/Class 2b 11 Increasing Process Capacity in The Goal “is to increase the capacity of only the bottlenecks” – “ensure the bottlenecks’ time is not wasted” » increase availability of bottleneck resources » eliminate non-value added work from bottlenecks reduce/eliminate setups and changeovers » synchronize flows to & from bottleneck – “ reduce starvation & blockage the load of the bottlenecks (give it to non-bottlenecks)” » move work from bottlenecks to non-bottlenecks » need resource flexibility – unit capacity and/or » invest #of units. OM&PM/Class 2b 12 Pricing and Capacity Investment: Trays + Rent another oven at $10/hr? Resource cost = Material cost = Minimum sale price = Contribution margin if sale price is $5 / dozen = OM&PM/Class 2b 13 Other factors affecting Process Capacity Batch (Order) Sizes Product Mix other managerial policies ... OM&PM/Class 2b 14 Chocolate Chip and Peanut Butter Data Flavor Clean Spoon on Load and Bake Bowl and Tray Set Oven Mix Cool Pack Into Box Receive Payment Chocolate 6 min Chip 2 min / doz 1 min 9 min 5 min 2 min / doz 1 min Peanut Butter 2 min / doz 1 min 7 min 3 min 2 min / doz 1 min 9 min OM&PM/Class 2b 15 Class 2b Learning Objectives CRU: manage better with the three key operational measures and an inter-functional macro process view of the organization Process measures: – Flow time manage critical activities – Capacity manage bottleneck resources Levers for improving – Flow time manage critical activities – Capacity & Throughput Process capacity depends on a zillion things OM&PM/Class 2b 16