Hartley - Business Case for HRO

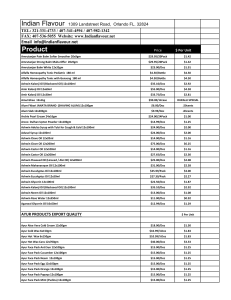

advertisement

HPRCT Workshop June 21-25, 2010 Richard S. Hartley, Ph.D., P.E. This presentation was produced under contract number DE-AC04-00AL66620 with An organization that repeatedly accomplishes its high hazard mission while avoiding catastrophic events, despite significant hazards, dynamic tasks, time constraints, and complex technologies A key attribute of being an HRO is to learn from the organization’s mistakes Aka a learning organization 2 3 SYSTEM ACCIDENT TIMELINE 1979 - Three Mile Island 1984 – Bhopal India 1986 – NASA Challenger 1986 – Chernobyl 1989 – Exxon Valdez 1996 – Millstone 2001 – World Trade Center 2005 – BP Texas City 2007 – Air Force B-52 2008 – Stock Market Crash What is Next? Who is Next? Some types of system failures are so punishing that they must be avoided at almost any cost. These classes of events are seen as so harmful that they disable the organization, radically limiting its capacity to pursue its goal, and could lead to its own destruction. Laporte and Consolini, 1991 5 Is it right for you? 6 DOE TRC and DART Case Rates All DOE TRC Rate All DOE DART Case Rate Cases per 200,000 workhours 4.00 3.50 3.00 2.50 2.00 1.50 1.00 Contractor ISM deployed 0.50 0.00 1993 1994 1995 1996 1997 1998 1999 2000 2001 2002 2003 2004 2005 2006 2007 2008 YEAR Data as of 7/7/2009 DOE injury rates have come down significantly since Integrated Safety Management (ISM) was adopted 7 Cost (¢/kwh) Rx Trips/ Scrams Capacity Factor (% up) Significant Events/Unit Nuclear Energy Institute (NEI) Data 8 Individual Accidents OR Systems Accidents? 9 An accident occurs wherein the worker is not protected from the plant and is injured (e.g. radiation exposure, trips, slips, falls, industrial accident, etc.) Plant (hazard) Human Errors (receptor) Focus: Protect the worker from the plant 10 An accident wherein the system fails allowing a threat (human errors) to release hazard and as a result many people are adversely affected Workers, Enterprise, Surrounding Community, Country Plant (hazard) Human Errors (threat) Focus: Protect the plant from the worker The emphasis on the system accident in no way degrades the importance of individual safety , it is a pre-requisite of an HRO 11 Goal of a High Reliability Organization Strive daily for High Reliability Operations A systems approach Every individual is not going to have a perfect day every day To avoid the catastrophic accident a systems approach is required 12 Reality Engineering Understanding Socio-Technical Systems to Improve Bottom-Line 13 a New Initiative TheNot most important thing, Way to Think is Logical, to keep Defensible the most important thing, Based onimportant Logic & Science the most thing. Logic & Science are Time and New th Steven Covey, 8 Habit Initiative Invariant Focus on what is important Measure what is important 14 Take a physics-based system approach Measure gaps relative to physics-based system Explicitly account for people People are not the problem, they are the solution People are not robots, pounding won’t improve performance People provide safety, quality, security, science etc. Sustain behavior – account for culture Improve long-term safety, security, quality 15 Spectrum of Safety Hard Core Safety Physics • Physics invariant • Prevent flow of unwanted energy • Delta function As Engineers Write Squishy People Part of Safety • Average IQ of the organization • It is a systems approach • Gaussian curve As People Do Spectrum of Safety Hard Core Safety Physics • Physics invariant • Prevent flow of unwanted energy • Delta function Old Mind-Set Compliance-based safety Squishy People Part of Safety • Average IQ of the organization • It is a systems approach • Gaussian curve High Reliability Organization Explicitly consider human error Take into account org. culture Maximize delivery of procedures Improve system safety Step #1: Ensure the operation has a defined and justified safety basis Step #2: Develop and deploy HRO framework to use strengths of organization to maintain safety Step #3: Measure performance of organization to safety basis Step #4: Leverage organizational learning to reduce variability to following safety basis 18 Step #1: Ensure the operation has a defined and justified safety basis Understand physics and chemistry of processes Unsafe Zone Do not Operate Zone (DOZ) 19 Unsafe Zone Violates physics of safety High consequence event In the red part of the unsafe zone and as delineated by the deterministic line, there are some levels of physics beyond which the outcomes (consequences) are certain. 20 Unsafe Zone Violates physics of safety High consequence event DOZ (don’t operate zone signified by orange cloud) The orange cloud signifies the DOZ (don’t operate zone). It extends to the unsafe zone (red circle) and signifies that area which because of uncertainty we try to stay out of by establishing conservative margins of safety. 21 Step #1: Ensure the operation has a defined and justified safety basis Understand physics and chemistry of processes Unsafe Zone Do not Operate Zone (DOZ) Define and justify safety basis relative to Unsafe Zone and DOZ Ensure individual processes are within safety basis Ensure collective processes are within safety basis Determine margin of safety 22 Unsafe Zone The safe zone/safety basis (green oval) represents a physics-based zone bounded with hazard analyses and defined using operating procedures. Violates physics of safety High consequence event DOZ (don’t operate zone signified by orange cloud) Safe Zone - Safety Basis Assured safety based on physics Processes if followed (i.e. stay within safety basis) assures safety 23 Unsafe Zone Violates physics of safety High consequence event DOZ (don’t operate zone signified by orange cloud) Safe Zone - Safety Basis Assured safety based on physics The Margin of Safety represents the gap between the established safety basis and the unsafe zone. Processes if followed (i.e. stay within safety basis) assures safety Margin of Safety (i.e. safety factors) 24 Step #2: Develop and deploy HRO framework to use strengths of organization to maintain safety Compliance-based safety Work-as-imagined equals work-as-done, except Bad apples 25 Unsafe Zone Based on assumption that most people will follow established safety rules. Regulation and oversight ensure compliance with established safety basis. Violates physics of safety High consequence event DOZ Engineer’s Field of Dreams Build it and they will come (don’t operate zone signified by orange cloud) Safe Zone - Safety Basis Assured safety based on physics Processes if followed (i.e. stay within safety basis) assures safety Margin of Safety (i.e. safety factors) work-as-imagined = work-as-done Management assumes workas-imagined equals work-asdone 26 Those that don’t follow established safety systems are just those few bad apples that need to be removed. Why do we remove “bad apples?” Unsafe Zone Violates physics of safety High consequence event They represent the $ M lesson learned! DOZ (don’t operate zone signified by orange cloud) bad-apples bad-apples X Safe Zone - Safety Basis Assured safety based on physics Processes if followed (i.e. stay within safety basis) assures safety Margin of Safety (i.e. safety factors) work-as-imagined = work-as-done 27 Step #2: Develop and deploy HRO framework to use strengths of organization to maintain safety Compliance-based safety Work-as-imagined equals work-as-done, except Bad apples HRO Approach to safety Reality between work-as-imagined vs. work-as-done Socio-technical systems Explicit consideration of the affect of organizations on technical safety 28 Green cloud signifies organizations’ struggles to stay within safety basis. Unsafe Zone Violates physics of safety High consequence event DOZ (don’t operate zone signified by orange cloud) Safe Zone - Safety Basis Assured safety based on physics Processes if followed (i.e. stay within safety basis) assures safety work-as-imagined work-as-done 29 Unsafe Zone Violates physics of safety High consequence event DOZ (don’t operate zone signified by orange cloud) Holes in safety basis because of poor analysis (potentially drops you into the DOZ). Safe Zone - Safety Basis Assured safety based on physics Processes if followed (i.e. stay within safety basis) assures safety work-as-imagined work-as-done 30 Unsafe Zone Violates physics of safety High consequence event DOZ (don’t operate zone signified by orange cloud) Safe Zone - Safety Basis Assured safety based on physics . Every excursion into DOZ decreases margin of safety. Processes if followed (i.e. stay within safety basis) assures safety work-as-imagined Reduced Margin of Safety work-as-done 31 Unsafe Zone Violates physics of safety High consequence event DOZ (don’t operate zone signified by orange cloud) Safe Zone - Safety Basis Assured safety based on physics Processes if followed (i.e. stay within safety basis) assures safety work-as-imagined work-as-done HROs: Explicitly consider how the organizational behavior affects ability to buy-in to the established safety basis. Attempt to leverage this to improve the margin of safety. 32 Builiding a High Reliability Organization 33 • Ensure system provides safety • Manage system, evaluate variability • Foster culture of reliability • Model organizational learning • Generate decisionmaking info • Tiered approach • Refine HRO system HRO Practice #1 HRO Practice #2 Manage the System, Not the Parts Reduce Variability in HRO System HRO Practice #4 HRO Practice #3 Learn & Adapt as an Organization Foster a Strong Culture of Reliability • Deploy system • Evaluate operations – meas. variability • Adjust processes •Provide capability to make conservative decisions •Make judgments based on reality •Openly question & verify system 34 The Limits of Safety, Scott D. Sagan Normal Accidents – Living with High-Risk Technologies, Charles Perrow Managing the Unexpected, Karl E. Weick & Kathleen M. Sutcliffe Managing the Risks of Organizational Accidents, James Reason Organizational Culture and Leadership, 3rd ed., Edgar Schein Field Guide to Human Error Investigations, Sidney Dekker The 8th Habit, From Effectiveness to Greatness, Stephen Covey Pantex High Reliability Operations Guide Pantex Causal Factors Analysis Handbook 35 36