net occupiable floor area - Mechanical Inspectors of Michigan

advertisement

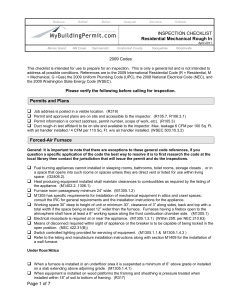

Code changes to 2009 Michigan Mechanical Code Commercial Installations – Not 1 & 2 family residences – unless not covered in MRC Definitions Chapter 2 • BREATHING ZONE. The region within an occupied space between planes 3 and 72 inches (76 and 1829 mm) above the floor and more than 2 feet (610 mm) from the walls of the space or from fixed air-conditioning equipment. • ZONE. One occupiable space or several occupiable spaces with similar occupancy classification (see Table 403.3), occupant density, zone air distribution effectiveness and zone primary airflow rate per unit area. Formerly known as the Occupiable zone. Definitions continued NET OCCUPIABLE FLOOR AREA. The floor area of an occupiable space defined by the inside surfaces of its walls but excluding shafts, column enclosures and other permanently enclosed, inaccessible and unoccupiable areas. Obstructions in the space such as furnishings, display or storage racks and other obstructions, whether temporary or permanent, shall not be deducted from the space area. OCCUPIABLE SPACE. An enclosed space intended for human activities, excluding those spaces intended primarily for other purposes, such as storage rooms and equipment rooms, that are only intended to be occupied occasionally and for short periods of time. A/C Pads • 304.10 Clearances from grade. Equipment and appliances installed at grade level shall be supported on a level concrete slab or other approved material extending not less than 3 inches above adjoining grade or shall be suspended not less than 6 inches above adjoining grade. Such support shall be in accordance with the manufacturer’s installation instructions. Condensate Disposal 307.2.1 Why is tool not being used by certain contractors? • 307.2.1 Condensate disposal. Condensate from all cooling coils and evaporators shall be conveyed from the drain pan • outlet to an approved place of disposal. Such piping shall maintain a minimum horizontal slope in the direction of discharge of not less than one-eighth unit vertical in 12 units horizontal (1-percent slope). • Added for A/C Coils Good Bye ASHRAE Handbook of Fundamentals • HEATING AND COOLING LOAD CALCULATIONS • 312.1 Load calculations. Heating and cooling system design loads for the purpose of sizing systems, appliances and equipment shall be determined in accordance with the procedures described in the ASHRAE/ACCA Standard 183. Alternatively, design loads shall be determined by an approved equivalent computation procedure, using the design parameters specified in Chapter 3 of the International Energy Conservation Code. • Chapter 4 is been completely remodeled to a type of ASHRAE 62 • Section 403 & Table 403.3 Minimum Ventilation rates has been completely revised. • Calculations is 3 -4 Step process depending on application . • Time constraints will not allowed to this to be covered. Intake opening 401.4 506.3.12.3 Termination location • 3. Intake openings shall be located not less than 3 feet below contaminant sources where such sources are • located within 10 feet of the opening. • ( Previous 2 feet) 501.2.1 Location of Exhaust outlets • • • • • • • • • • • • • 5. For specific systems see the following sections: Clothes dryer exhaust, Section 504.4. 5.2. Kitchen hoods and other kitchen exhaust equipment , Sections 506.3.12, 506.4 and 506.5. 5.3. Dust stock and refuse conveying systems, Section 511.2. 5.4. Subslab soil exhaust systems, Section 512.4 5.5. Smoke control systems, Section 513.10.3 5.6. Refrigerant discharge, Section1105.7 Machinery room discharge, Section 1105.6.1 Revised for to facilitate code usage Dryer Vent Penetration through ceiling or wall Fire Caulked. • 501.2.2 Exhaust opening protection. Exhaust openings Exhuast openings was moved to here from chapter 4 • 504.2 Exhaust penetrations. Where a clothes dryer exhaust duct penetrates a wall or ceiling membrane, the annular space shall be sealed with noncombustible material, approved fire caulking or a noncombustible dryer exhaust duct wall receptacle. Make up air required • 505.2 Makeup air required. Exhaust hood systems capable of exhausting in excess of 400 cfm (0.19 m3/s) shall be provided with makeup air at a rate approximately equal to the exhaust air rate. Such makeup air systems shall be equipped with a means of closure and shall be automatically controlled to start and operate simultaneously with the exhaust system. • Mixed Hoods • 507.2.4 Extra-heavy-duty. Type I hoods for use over • extra-heavy-duty cooking appliances shall not cover • heavy-, medium- or lightduty appliances. Such hoods shall • discharge to an exhaust system that is independent of other • exhaust systems. • Bath Fans in plenums. • 601.4 Contamination prevention • Exception: Exhaust systems located in ceiling return air • plenums over spaces that are permitted to have 10 percent • recirculation in accordance with Section 403.2.1, Item 4. The exhaust duct joints, seams and connections shall comply with Section 603.9. Round duct joints • 603.4.1 Minimum fasteners. Round metallic ducts shall be mechanically fastened by means of at least three sheet metal screws or rivets spaced equally around the joint. • Exception: Where a duct connection is made that is partially in accessible, three screws or rivets shall be equally spaced on the exposed portion so as to prevent a hingeeffect. Ducts in a garage • 603.7 Rigid duct penetrations. Ducts in a private garage and ducts penetrating the • walls or ceilings separating a dwelling from a private garage shall be continuous and constructed of a minimum 26 gage • galvanized sheet metal and shall not have openings into the garage. Fire and smoke dampers are not required in such ducts passing through the wall or ceiling • separating a dwelling from a private garage except where required by Chapter 7 of the International Building Code . SEALING DUCT JOINTS • 603.9 Joints , seams, and connections. • Exception: Continuously welded and locking-type longitudinal joints and seams in ducts operating at static pressures less than 2 inches of water column pressure classification shall not require additional closure systems. Chapter 7 abducted by Aliens (NFPA) • 701.1 Scope. Solid fuelburning appliances shall be provided with combustion air in accordance with the appliance manufacturer’s • installation instructions. Oilfired appliances shall be provided with combustion air in accordance with NFPA 31. Refrigeration Piping • 1107.2 Piping location. Refrigerant piping that crosses an open space that affords passageway in any building shall be not less than 7 feet 3 inches • 1107.2.1 Piping in concrete floors. Refrigerant piping installed in concrete floors shall be encased in pipe ducts. The piping shall be isolated and supported to prevent damaging vibration, stress and corrosion. • 1107.2 Piping location. • Refrigerant penetrations. Refrigerant piping shall not penetrate floors, ceilings or roofs. With exceptions…… Hydronic System Drain Down • 1206.2 System drain down. Hydronic piping systems shall be designed and installed to permit the system to be drained. • Exception: The buried portions of systems embedded underground or under floors. Radiant Heating sytems • 1209.5 Thermal barrier required. Radiant floor heating systems shall be provided with a thermal barrier in accordance with Sections 1209.5.1 through 1209.5.4. (R- 5 & Thermal break required) Bubble wrap won’t work either. Other Changes not in the code • NOTES: • Grease Duct • 1. For uninsulated air Enclosures UL ducts and air connectors, standard has changed. disregard references to • Double wrap required. insulation and jacket. • Flexible duct instructions require “beaded fittings” • 2. Use beaded sheet metal fittings and sleeves when using nonmetallic clamps. • 3. Use tapes listed and labeled in accordance with Standard UL 181B and marked “181B-FX”.