Community Development - Southeastern Arizona Contractors

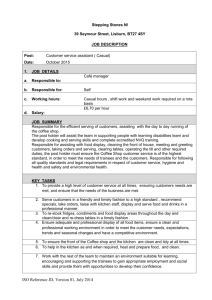

advertisement