Apa itu Energi Geothermal

advertisement

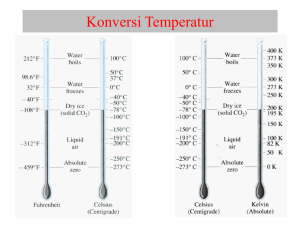

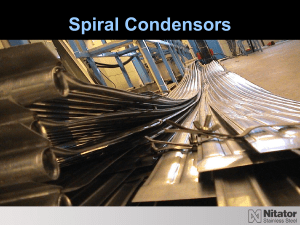

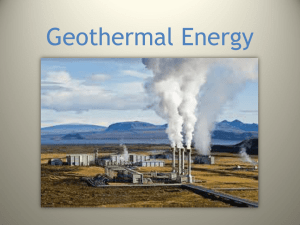

The term geothermal comes from the Greek geo meaning earth and therme meaning heat thus geothermal energy is energy derived from the natural heat of the earth.. The earth’s temperature varies widely, and geothermal energy is usable for a wide range of temperatures from room temperature to well over 300° F. For commercial use, a geothermal reservoir capable of providing hydrothermal (hot water and steam) resources is necessary. Geothermal reservoirs are generally classified as being either low temperature (<150° C) or high temperature (>150° C). Generally speaking, the high temperature reservoirs are the ones suitable for, commercial production of electricity. Geothermal reservoirs are found in “geothermal systems” which are regionally localized geologic settings where the earth’s naturally occurring heat flow is near enough to the earth’s surface to bring steam or hot water to the surface Power plants using dry steam systems were the first type of geothermal power generation plants built. They use the steam from the geothermal reservoir as it comes from wells, and route it directly through turbine/generator units to produce electricity. An example of a dry steam generation operation is at the Geysers in northern California Hot water geothermal reservoirs are the most common type. In a liquiddominated reservoir, the hot water has not vaporized into steam because the reservoir is saturated with water and is under pressure. To generate electricity, the hot water is piped from geothermal wells to one or more separators where the pressure is lowered and the water flashes into steam. The steam then propels a turbine generator to produce electricity. Based on Juli 2004 data: 40 % total geothermal on the word. Range capacity: 3 MW – 90 MW On the same geothermal fluid condition 15 – 20% more power output. A binary cycle power plant is used when the water in a hot water reservoir is not hot enough to flash into steam. Instead, the lower-temperature hot water is used to heat a fluid that expands when warmed. The turbine is powered from the expanded, pressurized fluid. Afterwards, the fluid is cooled and recycled to be heated over and over again. Fluid Formula Mollar mass Relative Exit Area Ammonia NH3 17.03 1.0 Propane C3H8 44.09 1.9 i-Butane i-C4H10 58.12 4.9 n-Butane C4H10 58.12 6.3 i-Pentane i-C5H12 72.15 12.2 n-Pentane C5H12 72.15 14.6 Condition: Turbine inlet temperature 400 K Condensing Temp: 320 K Geothermal energy is a renewable energy source that does little damage to the environment. Geothermal steam and hot water do contain naturally occurring traces of hydrogen sulfide (a gas that smells like rotten eggs) and other gases and chemicals that can be harmful in high concentrations. Geothermal power plants use "scrubber" systems to clean the air of hydrogen sulfide and the other gases. Sometimes the gases are converted into marketable products, such as liquid fertilizer. Newer geothermal power plants can even inject these gases back into the geothermal wells. Geothermal power plants do not burn fuels to generate electricity as do fossil fuel plants. Geothermal power plants release less than one to four percent of the amount of carbon dioxide (C02) emitted by coal plants. Emissions of sulfur compounds from motor vehicles and fossil fuel plants are also major contributors to acid rain. Geothermal power plants, on the other hand, emit only about one to three percent of the sulfur compounds that coal and oilfired power plants do. Well-designed binary cycle power plants have no emissions at all. Geothermal power plants are compatible with many environments. They have been built in deserts, in the middle of crops, and in mountain forests. GEOTHERMAL Relatively smaller unit size (Max. 110MW) makes unit construction cost high (because of (1) availability of geothermal steam; (2) difficulty of transportation to geothermal power plant located in mountainous area; (3) limitation of turbine last blade length.). CONVENTIONAL STEAM POWER PLANT The size can be decided depending on power demand, availability of fuel, etc. Plant size and unit size are big (600 to 1,000MW) makes unit construction cost low. CONVENTIONAL STEAM POWER PLANT GEOTHERMAL Because steam pressure is relatively low (Usually 6 to10 bara, Max. 19 bara), size of the turbine is bigger compared to thermal power plants of the same capacity All stainless steel (316L) or stainless clad steel because of NCGs. High steam pressure (about 90 bara) makes size of steam turbine small Depend on available main cooling water. GEOTHERMAL Because geothermal power plants are usually located in mountainous area where sufficient cooling water is not available, cooling tower is mandatory. CONVENTIONAL STEAM POWER PLANT N/A: Because most of thermal power plants are located at sea side for fuel transportation and cooling (sea) water, cooling tower is not necessary STEAM POWER PLANT Reference Data Steam Flow (ton/Hr) Output (kW) at 145t/h P1 (bara) Turbine Inlet Steam Condition Turbine Outlet Steam Condition Theoretical heat drop 145 34,179 145 (= 40.28 kg/s) 20,000 1.71 times 87.3 8 T1 (deg C) 510 170 h1 (kJ/kg) 3,415 2,767 s1 (J/kg K) 6,709 6,660 0.09 0.11 T2 (deg C) 44 48 s2 (J/kg K) 6,709 6,660 0.80 0.80 h2 (kJ/kg) 2,112 2,120 Δh (kJ/kg) 1,302 647 52,457 26,067 P2 (bara) Theorotical Calculation GEO THERMAL X2 Theoretical output (kW) at 145t/h 2.01 times Equipment / System Thermal Geothermal Fuel System Yes N/A Boiler Yes N/A Turbine Yes Yes Condenser Yes Yes Boiler Feed Water System Yes N/A Cooling Tower N/A Yes Small Big Yes N/A Yes (1) N/A Gas Extraction System Feed Water Treatment System Flue Gas De-sulferization Equipment (2) Depend on Environmental Regulation The main cooling system of the main condenser comprises : the two main circulating pumps 50 %, the cooling tower, the piping and valves. The cooling system of the geothermal plant comprises a cooling tower of natural draught or forced draught type whose function is to discharge to atmosphere the waste heat rejected at the condenser. Considering the flow range of water to be cooled (average 6,500 m3/h for 20 MW unit / 15,900 m3/h for 55 MW unit) a forced draught tower with air directed through the tower by means of a fan, is the most suitable type for this application. The auxiliairy cooling water system shall comprise The primary auxiliary cooling water system, The secondary auxiliary cooling water system. Primary auxiliary cooling water system The primary auxiliary cooling water system is derived from the cooled water of the cooling tower and shall be designed : To ensure steam condensation inside the two ejectors condensers, To ensure the heat dissipation of the secondary auxiliary cooling system. The secondary auxiliary cooling water system is a closed circuit fed from the treated fresh water system ensuring cooling of the turbo-generator coolers through the two water/water exchangers. This system shall mainly include : The two secondary auxiliary cooling pumps, The two water/water exchangers, A make up tank. The turbo-generator air-coolers, The generator air-coolers, The air compressors coolers (if compressed air system water cooled), Various small coolers,