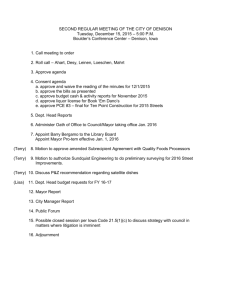

ENVIRONMENTAL_MONITORING_SYSTEM_NOVATEK_INT

advertisement

User requirements of a comprehensive ENVIRONMENTAL MONITORING software system Susan B. Cleary Current Practices Legacy systems – pre 1997 Spread sheets – non-compliant In-house systems – Maintenance / upgrade / Regulatory changes Benefits of a Comprehensive System All data is managed and contained in one system. (for all sites) All data can be easily analyzed expediting problem detection Data integrity and security Regulatory compliance User Requirements Specific (easily understood) Attainable (realistic) Prioritized Traceable – (requirement ~ design ~ validation) Compliant to 21 CFR part 11 What are the requirements in a Comprehensive EM Software System? Define the Workflow Utilities and Controlled Environment Manage users Register and schedule tests Generate summaries Distribute worksheets Enter results Statistical analysis Reporting Manage System Users Multiple security levels Limited access Concurrency – Data integrity Event Notification Set-up Test Protocols Controlled Environment Test type (Rodac, Settle plate, Air sample,…) Viable (Bacteria,Yeast/Mold) Non-Viable (Particle counts) Location Location classification Static/Dynamic specifications Static/Dynamic scheduling Prepare/Review/Approve Set-up Test Protocols Utilities Utility type – Clean steam – Water (Source,Lab, Purified,WFI, …) – Gas (CO2, Compressed Air, Nitrogen, …) Valve/Port and Loop Test type (TOC, Bio-burden, Heavy metal (EP)) Specifications (alert, action, control) Scheduling Prepare/Review/Approve Recurrence patterns Set-up Test Protocols Personnel Monitoring Test type (Gowning, Finger dabs, …) Location Specifications Scheduling Prepare/Review/Approve Personnel Monitoring Mapping Room template Personnel template Adding test locations Multiple rooms Secure file storage Audit trail Mapping Import from other file formats Floor plan Test location definition Bar-coding Sample tracking Labels Fonts (code 128, code 39) Self contained Configure with existing labeling Generating Summary Sheets Creating only what is required Based on protocol scheduling Static or dynamic specs Distribution of Worksheets Scheduled testing lists Printed maps Bar code labels Sample status Data entry Data organization and the effect on data entry Detail data entry – Incubators – Exposure times – Personnel contact –Equipment –Product lot number –Media lot number Data entry using bar-codes Complete/Review/Approve Handling Excursions Designating excursion values – Pathogenic – Alert/Action/Control levels Visual cue Differentiation between spec levels Email notification Investigation initiation prompt Microbial Identification Multiple Identifications File attachments Prepare/Review/ Approve Investigations Action Follow-up Final decision Completion and approval Visual cue Master list 21 CFR part 11 Electronic signatures Time stamps User logs Change controls Audit trails Record retention (Back up and Archiving) Statistical Output Trend basis – User – Location – Test type and location – Microorganism Statistical Output Graphic display – Scatter plots – Bar charts – Pie charts – Regression analysis Reports Default reports – Protocols – Summaries – Worksheets Company specific requirements – Logos – Custom formatting Free Format Query Dynamic field selection Alpha or numeric field detection Graphic display Printed report Archiving Free-up current database space Access the data on demand Storage of past data – Audit trail – Version control EM Software Implementation Define lab requirements – Current state – Future improved state User requirements/Design specification – Gap – Configuration EM Software Implementation Training by user type – Power users (system administrators) – Standard users Three phase training – Demonstration – Hands on – Question and Answer Evaluation and sign off EM Software Implementation Validation – Installation Qualification – Operational Qualification – Performance Qualification Traceability matrix Standard Operating procedures (back up/recovery) EM Software Implementation Gap Analysis – Defending the system – Meets with internal SOPs Measure performance – Increased lab productivity Additional Information To request additional information about Novatek’s EM Software Application, you may contact: Aty Heidari Manager of Technical Sales E-mail: Aty.Heidari@ntint.com Tel.: (514)336-6809