Malcolm Meats A SYSCO Specialty Meat Company

advertisement

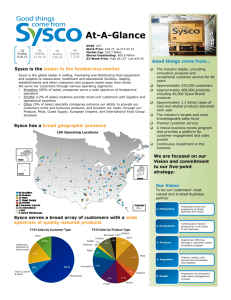

Welcome to Malcolm Meats A SYSCO Specialty Meat Company Malcolm Meats first opened it’s doors in May of 1982. Over the years we’ve made it our mission to provide the highest standard of customer service and to present to our customers the very finest cuts of beef, lamb, pork, and veal quality unmatched. In 1999 we became part of the SYSCO family. Today, under the guidance of our senior staff who have 87 years of combined experience, we continue to expand our facility, our knowledge, and our level of commitment to our customers. We never stop striving to be better. We welcome you to our Ohio or Illinois facility at any time for a personally guided tour, but until then – here is a quick look at what we are about………. Our staff make it their business to understand every aspect of the market and they put that knowledge to work to ensure our customers get the best product. We also host training sessions and conduct plant tours so our customers are well informed and can see first hand how we put it all together for them. When a delivery arrives to our dock or shipments are made from our dock, both the product and truck are temperature checked. If either do not meet our strict criteria – the delivery is not accepted. All temperatures are recorded on our daily log for further review and compliance with HACCP’s cold chain requirements. We have 35,000 square feet of production facility, aging cooler and freezer storage. We have a well trained Customer Service department who know what personal service is all about. We know your time is valuable so when you call us you get to speak to us. You aren’t left on hold, you aren’t put through a confusing series of button options and you will never get voice mail. A real person answers your call the first time, every time. Our Production Supervisor monitors the flow of orders going to the cutting floor. He reviews and maintains control of each order to ensure accuracy and timely processing of each cut ticket. Product is brought in to our opening room direct from the aging cooler. This helps in bleeding out the product prior to entering the cutting room. A cut ticket follows each item processed and provides every department with all the information they need to carry this order from telephone to truck. Cut tickets are color coded to represent each Opco we work for. It has the SUPC, a complete item description including special instructions, case count, weight, processor and order number with shipping date. An example of our cut ticket, showing the date and time of the order, delivery date, order number, customer number, quantity, product description and any special instructions. Trained employees work at prepping stations to trim product and prepare it for the cut tables for further processing by our top rate cutters. One of our skilled cutters processing an Export Rib into a Frenched Rib Steaks (Cowboy). Our experienced cutters work independently at their stations and take personal ownership and great pride in every steak they process. An Export Rib is being processed into a Frenched Rib Steak (Split Bone Cowboy). Notice the steak on the scale at his station. Every single steak hits a scale in our cutting facility. Due to the fact we are a portion control company every steak must be precise to our customers specifications. We use a skinner to remove silver from tenderloins and teres major muscle. This gives us a better yield, which results in better pricing. And the meat does not have grooves or high spots from normal knife work. We have three Beef Saws managed by very talented people. We consistently put out beautifully trimmed product. Our facility is equipped with high tech slicing machines that are computer programmed to meet any required specification. . We have check points in place to guarantee our customers’ specifications are met. We needle tenderize both bone-in and boneless beef products. This process helps ensure your customer gets a tender product, every time. In our vacuum tumblers we create marinated items for National Accounts as well as stock products for the Sysco Operating Companies. In our Pork Room we use only red lugs to easily identify pork products and to avoid cross contamination with beef. We provide all processed pork items. Our packaging room has the finest equipment available. This state of the art packaging equipment ensures a longer shelf life for the end user. All product is stamped with an easy to read freeze by date. 21 days from pack date for beef and 14 days for pork. The number “11” indicates which packer the product came from. The letter tells us which packaging machine it went through. We have equipment to provide not only individual vaccuum packaging, but we also offer bulk vaccuum packaging for those large parties and or catering events. . After going through the vac machine product passes through our Metal Detector. Metal detection is a SYSCO requirement and not a USDA mandate. Product drops into totes to be taken to the boxing area. In our boxing area each box is weighed and labeled on each end panel. We also tape all boxes for a tamper evident product which is a SYSCO requirement. Labeling is a very important part of our operation. Each label will have the SUPC code, pieces per case, product identification, weight and USDA grade. We can also tell the pack date, who packed the product and even who the raw material came from. You will never see any handwriting on our boxes. While Malcolm Meats strives to produce the highest quality, safest product available in the industry, we also realize the importance of retaining traceability of our products in case of a problem. We have detailed steps in place for tracing raw material, work in progress, re-worked product, finished product and by-products. And it’s not just instructions in a book. We conduct a minimum of 2 mock recalls per year to make sure steps are understood and followed properly by our staff. Time is of the essence during a recall and part of our testing and training is in making sure every item is accounted for and verified in as little time as possible. All product shipped is logged and files are maintained for not less than one year. Logs contain truck identification, route, and fresh and frozen truck temperature with product identification. In addition a visual inspection of the trailer must be performed and any deficiencies and corrective actions noted. This log is reviewed by the QA Mgr. While all SYSCO Specialty Meat Companies are USDA inspected, there is also a team of Quality Assurance professionals at the corporate level who are responsible for ensuring the SSMC’s meet the SYSCO quality and food safety standards. SYSCO’s QA department is the largest in the industry. With over 180 professionals located around the world, this team is dedicated to only one mission: to deliver products that meet the most exacting standards in terms of quality, safety and consistency. They especially focus on inspection of key product lines that may be subject to greatest variations, such as fresh and processed meat products. SYSCO specifications meet or exceed all applicable government grading standards and inspection requirements. Following are some of the regulatory and corporate mandated programs that Malcolm Meats has implemented to ensure their customers are receiving the safest products available. Hazard Analysis and Critical Control Point (HACCP) Sanitation Standard Operating Procedures (SSOP) ATP and Environmental Testing Metal Detection Approved Supplier Program Blind Cuttings Food Security Not only does Malcolm Meats require their suppliers to undergo third party sanitation and food safety audits, we are also required to undergo a yearly third party audit. SYSCO requires that all SSMC’s score at least a 92% (920/1000) a high mark by any standard. Malcolm Meats has exceeded that score every year. AIB Food Safety Audit – 2002 – Superior rating of 97.0% AIB Food Safety Audit – 2003 – Superior rating of 96.0% AIB Food Safety Audit – 2004 – Superior rating of 94.5% AIB Food Safety Audit – 2005 – Superior rating of 95.0% AIB Food Safety Audit - 2006 – Superior rating of 98.9% There is a new trend developing in the meat industry, and SYSCO and Malcolm Meats are leading the way in the Foodservice Sector, not only in quality and food safety, but in all areas of the business, from finance to ethics. No other foodservice company can compare to the interactive support and resources provided to the SYSCO companies by its corporate office and the wide exchange of knowledge exhibited by the SSMC’s themselves. SYSCO and Malcolm Meats have achieved superiority through hard work, dedication, and innovation ….. And that is the SYSCO difference.