Stage 3 Design - Water Environment Association of Ontario

advertisement

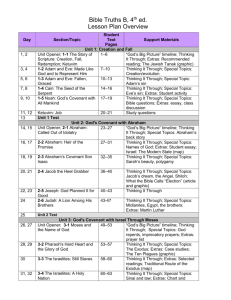

Expansion of the Newcastle Water Pollution Control Plant WEAO Student Design Competition 2013 Contents Introduction Stage 3 Design Stage 3 Extras Stage 4 Layout Conclusions Questions? Introduction Who are we? Bradley Free 5 th Year Water Resource 5 th Kyle Lockwood 5 th Year Environmental Tanzeel Ahmed Year Environmental Robyn Thompson 4 th Year Mechanical Introduction Background An expansion is planned for the Durham Region Newcastle Water Pollution Control Plant (WPCP), in the Municipality of Clarington, Newcastle, Ontario The expansion of the WPCP is planned in four stages, to ultimately increase the capacity to six times that of the current operating capacity University of Guelph The Objectives: 1.Preliminary Design and layout for Newcastle WPCP for Stage 3 expansion including biosolids handling and energy recovery 2.Conceptual layout for Newcastle WPCP expansion for Stage 4 expansion Clarington, Ontario Stage 3 Design Population Analysis Stage 3 Design Population Analysis Selection of Processes Based on previous growth data from the municipality of Clarington Stage 3 to be completed when Stage 2 average day capacity reaches 75% of ADF Peak Flow rates were estimated using the Harmon formula Expected service capacity according to population growth against time The Layout and Design 45000 Secondary Treatment Tertiary Treatment Biosolid Handling and Treatment Average Inflows (m3/d) Receiving Station and Headworks Primary Clarification Average Inflow Rates 40000 Peak Inflow Rates 35000 30000 Stage 3 Completed: 2034 25000 20000 15000 10000 5000 0 2000 2020 2040 Population 2060 2080 Stage 3 Design The Layout 1. Office Building 2. Headworks 3. Primary Clarifiers 5. Secondary Clarifiers 9. Dewatering Units 6. Disinfection 10. Chemical Storage 7. Cloth Filters 11. Anaerobic Digesters 4. Aeration Tanks 8. Digester Gas Flaring 12. CHP System Stage 3 Design Receiving Station and Headworks Mechanically Cleaned bar screen installed Installed parallel to existing systems Increases existing treatment capacity Two additional aerated grit tanks installed Will be able to process Stage 3 flows of 39,300 m3/d Extra unit provided for redundancy and maintenance Stage 3 Design Primary Clarification Circular Primary Clarification tank installed Existing clarifier tank will be modified during stage 3 installation as a circular tank Will eliminate maintenance issues of gross solids buildup in corners of existing square clarifiers Performed during stage 3 installation Will reduce BOD and TSS sufficiently for ADF and PDF Stage 3 Design Secondary Treatment Two aeration tanks will be installed in parallel to existing tanks Aeration will operate as awill staged CAS process to allow Two newtanks secondary clarifiers be installed in parallel to existing operational flexibility clarifiers have First astage fitted withofjet50% aeration and diffuser grid Will recycle ratio Second has diffuser grid installed Clarifiers are stage sized to treat the maximum daily flow of 39,300 m3/d Can perform nitrification-denitrification for alkalinity recovery Will be consistent with existing plant systems Stage 3 of system will have an operational MLSS of 3500 g/m3 Will have an SRT of 12 days to achieve nitrogen removal Stage 3 Design Tertiary Treatment Alum Addition UV system UV3000Plus™) selected as best method eliminating Three Cloth (Trojan Filtration Units (AquaDISK Tertiary Filtration system)installed TSS Will reduce the influent phosphorus by over 85% current chlorine disinfection methods reduced below 5mg/L for ADF Will Added atchlorine thetoaeration tank effluent Current contact tank will act as a bypass be able process Stage 3 flows of 39,300 m3channel /d Extra Chosen because it monthly was most effective treatment for the Achieves desired geometric density of unit provided for the redundancy andmean maintenance lowest cost of Escherichia Coli 150cfu/100mL Low Pressure/ High Intensity (LP/HI) lamps Horizontal Parallel to flow lamp configuration Automatic chemical/mechanical cleaning Weighted Gate Automated Level Controller Stage 3 Design Sludge and Biosolid Treatment TM 2 Single stage highDisposal rate mesophilic anaerobic system digesters installed ROTAMAT (HUBER ) Screw Press dewatering chosen Processed Sludge parallel Stage agricultural 2 Digesters approved 2toDewatering units installed Stage On land site for under the3Durham Digesters will treat the throughout wasted solids from the primary clarifier and Have a total dry solids capacity of 280 kg Dry/h Region Works Department’s Biosolids Management the WAS from secondary clarifier centrifugal dewatering system O/M costs arethe smaller than traditional Program Operates SRT of 20at days <1.5 rpm screw rotation speed Requires External pump recirculation mixing <20 min/d of operator attention Produces Biogas collection for Combined Heat and Power (CHP) energy 18 – 25%tocake solids recovery The Extras CHP Energy Recovery The Extras CHP Energy Recovery Noise and Odour Control Hydraulic Profile Modelling Process Control and Instrumentation Construction Implementation Cost Analysis Captures the biogas produced from the Digesters and generate renewable energy Primary mover of the CHP system is 2 microturbines CHP Economic Feasibility Generate approximately $130,000/year in energy savings 11 Year Payback Period Dependent upon obtaining Electricity Contracts Fuel Gas Conditioning System will reduce H2S, CO2, PM extending the lifespan of the microturbines and reducing greenhouse gases Flare located southwest of the facility in case of CHP system failure The Extras Noise and Odour Control Problem: Development of surrounding residential area of great concern Solution? Adequate buffer areas around the facility Housing facilities with adequate noise depletion technology (for pumps, generators, etc.) All noise and odour sources will maintain the minimum separation distance of 100 meters in agreement to MOE odour and noise guidelines. The Problem Source: Google Maps 111m The Extras Hydraulic Profile E.L. 84.75m Available Head of 4.0m E.L. 80.75m The Extras Modelling STOAT® WRc’s waste water modelling software BOD, TSS and NH3 was modelled within the simulation At an operational temperature of 10oC, the effluent objectives were well below target Parameter BOD5 (10 mg/L) TSS (10 mg/L) (Ammonia + Ammonium) Nitrogen* Proposed Effluent Objectives Simulated Mean Effluent 10 mg/L 10 mg/L 9 mg/L 15 mg/L 4.76 mg/L 6.61 mg/L 0.49 mg/L *The simulated ammonia effluent is assumed to be representative of both ammonia and ammonium * Concentration listed are for summer and winter objective respectively The Extras Process Control and Instrumentation Supervisory Control and Data Acquisition (SCADA) Provides operational ease by reducing monotonous tasks for operators Overall efficiency of the plant improved by maintaining steady state process The Controls Headworks and Clarifiers Monitoring and pumping control Aeration Basin Dissolved oxygen monitoring Aeration efficiency improvements of up to 50% Monitoring and Pumping Tertiary Treatment Flow monitoring and splitting Digesters Monitoring performance Controlling temperature, pressure, recirculation and feed rates CHP Monitoring and controlling flow rates and energy production The Extras Construction And Implementation 2034 Dec Nov Oct Sep Aug Jul Jun May Apr Mar Feb Jan Dec Nov Oct Sep Aug Construction Period Mobilization and Erosion Control Systems Site Preparation Concrete Placing, Formwork and Reinforcing Steel Piping and Mechanical Equipment Installation Support Facilities Electrical Work, Instrumentation and Controls Landscaping and Final Clean-up Commissioning Duration (months) Task Name 2033 15 1 1 4 6 2 6 2 3 Minimizing Environmental Impact The completion date of Stage 3 is accordance with Local Municipalities, by-laws and MOE Standards PlantInDesign: 12 months established as year-end of 2034 Permits and Approvals: 12 months Using current data in the Noise Control Tendering/Awards: 2 months population analysis Dust Control Construction Period: 15 months Recommended that population Commissioning: 2 months Protection of Surface Water growth trends are rechecked every 5 years Erosion Control The Extras Cost Analysis Total Capital Cost: $26,350,000.00 9% 8% 19% 64% The Extras Cost Analysis Annual Operation and Maintenance Cost: $898,000.00 22% 53% 15% 6% 4% The Extras Stage 4 Layout Stage 1&2 Stage 43 Conclusions Conclusion Recommendations Acknowledgements Questions Further investigation should be conducted The proposed processes for Stage 3 includewith respect to the integration of the microturbine CHP Hongde Zhou, Ph.D., P.Eng. – Faculty Advisor Additional headworks improvements system for biogas handling Professor of the School of Engineering – University of Guelph Issues clarification such as the availability of 1 primary tank obtaining contracts from the Advisor Ontario Miles MacCormack , P.Eng. – Consultant 2 Manager two-staged aeration Project – Stantec Inc. Energy Board (OEB)tank and the Local Distribution Company (LDC) are of 1 secondary clarification tank Rafiq Qutub , M.Eng., P.Eng. concern Subcommittee Chair, Student Design Competition – Water 3 cloth filters Green incentive grants should be Environment Association of Ontario to determine possible 1 UVassessed disinfection unit alleviation Kirill Cheiko , EIT. of total capital cost and further Water – Stantec Inc. 2EIT additional anaerobic digesters evaluation of the systems feasibility Questions and… 2 screw press Yashar Esfandi , EIT.dewatering units Population growth trends are rechecked every Inside Sale Representative – SPD Sales Limited 5 years to determine if the completion of Stage 3 Stage 3 is toschedule be completed by year-end of 2034 construction requires Hussein Abdullah, Ph.D., P.Eng. –adjustment Director The School of Engineering – Guelph University present cost of $26.3 Million Obtain additional specific order costing O/M of $0.9 annually information fromMillion manufacturers Conclusions The Credits