Responsible CarE® Codes of Management Practices

advertisement

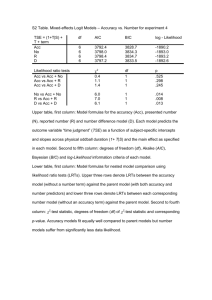

RESPONSIBLE CARE® CODES OF MANAGEMENT PRACTICES OVERVIEW Daniel Roczniak Senior Director, Responsible Care American Chemistry Council June 2010 Presentation Topics • Background on American Chemistry Council. • Responsible Care in the United States. • Responsible Care Codes – Purpose of the Codes – Issues addressed in the Codes – How to use in your organization • Using the Codes as continuous improvement tools. American Chemistry Council Background • Primary trade association representing the chemical industry in the United States. • Members represent approximately 85% of chemical production in the US. • ACC includes both SMEs and multinational companies. • “Owner” of Responsible Care® in US. • Providing support to GPCA as it develops regional Responsible Care program. Responsible Care® in US A Short History • ACC adopted Responsible Care in 1988. • Obligation of membership. • Extended program to companies in the transportation and storage sectors in 1993. • Strong CEO leadership element. • Focus on consensus-building to ensure broad support of the program. • Currently conducting a review, led by external parties, to identify opportunities to improve the program. ACC Responsible Care® Timeline Path to Continuous Improvement Goals and Targets (RC 3.5) Responsible Care 2.0 Aggregate Performance Metrics Peer Verification Process (MSV) Partner Program Enhanced Mutual Assistance 2009 Responsible Care 4.0 2003 1993 1988 Responsible Care 1.0 Guiding Principles Codes & Self-Evaluations Public Advisory Panel Mutual Assistance Responsible Care 3.0 Management Systems Transparent Metrics Reporting Security Code Third-Party Certification Increased Focus on Business Value Responsible Care® Codes of Management Practices The Codes of Management Practices are the tools of Responsible Care. By putting the codes in place, better safety and environmental performance and greater public openness will follow. ACC Report, 1995 Responsible Care® Codes of Management Practices • Initial deliverable was a set of Guiding Principles which identified the industry’s performance goals and expectations. • ACC companies needed a common roadmap with common language to achieve these goals and expectations. • Collectively improve performance in agreedupon key areas. Responsible Care® Codes of Management Practices • Decision was made to follow path established by Canadian industry and develop a set of codes. • Codes identify practices which all companies would implement in their organizations. • Codes are written to give companies flexibility in how to implement. • Companies reported implementation progress annually to ACC. Responsible Care® Codes of Management Practices • Codes address these areas of activity: – Pollution Prevention – Process Safety – Distribution – Employee Health and Safety – Community Awareness and Emergency Response – Product Stewardship – Security Responsible Care® Codes of Management Practices “Inside” the Facility Codes • Pollution Prevention • Process Safety • Employee Health & Safety • Security “Outside” the Facility Codes • Community Awareness & Emergency Response • Distribution • Product Stewardship • Security The scope of the codes is not totally inside or outside the facility. They all have elements that address issues on both sides of the fence line. Responsible Care® Codes of Management Practices • Companies were encouraged to identify a “steward” for each code who had responsibility for code implementation within the organization. • Through code implementation process, stewards would coordinate activities and break down organizational “silos.” • Required management to interact more directly with line workers. • Encouraged cooperation between EHS personnel and business leaders in the organization. Responsible Care® Codes of Management Practices • ACC developed a mandatory, annual self-assessment process to track company code implementation. • ACC used aggregate self-assessment results to determine where to direct resources to assist companies. • ACC also reported aggregate results to the public to demonstrate industry progress. • Within the companies, Responsible Care Coordinators tracked progress at each facility. • Expectation that CEOs were monitoring progress in their companies. Responsible Care® Codes of Management Practices • ACC codes were basis of mutual assistance and sharing activities for more than a decade. – Companies met regularly to benchmark against the codes. – Codes gave companies a common “language” when discussing EHS issues. – Allowed SMEs to interact with multinationals on an even footing. – Allowed ACC to identify “Examples of Excellence” for distribution to all members. – Created mechanism for “peer pressure” between individual companies and regions. – Created opportunities for individuals outside traditional EHS programs to participate in the program. – Served as the basis for workshops, seminars, etc. Responsible Care® Codes of Management Practices • Codes eventually were integrated into ACC Responsible Care management system. • Created a strong EHS and Security foundation for members and Partner companies. • Codes were the glue that bonded the membership in the early days of the program. That bond still exists today. • Codes remain tools in the ACC Responsible Care toolbox. • ACC Codes were adopted by many associations in Asia and South America during the 1990s.