Humidification in Healthcare Facilities

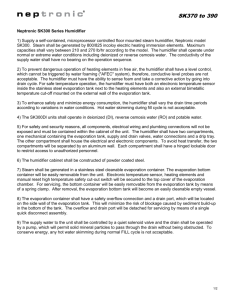

advertisement

Established in 1976 in Montreal Canada Design and manufacture innovative HVAC products HQ and manufacturing facility (80,000 sq ft) located in Montreal Worldwide distribution network; present in every continent WELCOME │ BIENVENIDO │ BIENVENUE HUMIDIFICATION Presentation 1. 2. 3. 4. 5. 6. 7. 8. Introduction to Humidification Why Humidity is so Important Why Should We Humidify Typical Applications Calculation Parameters Existing Local Variables Hardness of Water Types of humidifiers • Isothermal / Adiabatic 9. Isothermal • Electric Humidifier • • • • • Gas-Fired Humidifier Steam to Steam Humidifier Direct Steam Injection Humidifier • • 10. Resistive Electrode Multi-Steam Distribution Jacketed Tube Distribution Adiabatic • Atomizing Humidifier • • • • Air/Water Fogger High pressure Water Ultrasonic Humidifier Evaporative Humidifier Humidity: Water that is in gaseous form, vapour. Relative humidity (% RH): The amount of vapour in air at a specific temperature with respect to the maximum quantity of steam that can absorb without condensation. Humidification: This process occurs when the water has absorbed enough heat to evaporate. It requires about 1,000 Btu to evaporate one pound of water (2.326 kJ / kg). 70% of the planet is covered by water. The human body is composed of roughly 60% water by volume. The gaseous form of water is vapor and the measure of water vapor in the air we breathe is relative humidity. The amount of vapor the air can hold is dependent upon the temperature of the air. The warmer the air the more vapor it can hold. The reverse is true for cooler air. We function best at temperatures between 70 and 80 degrees and relative humidity of 40% to 60%. If the air is dry and hot we lose body water by evaporation very quickly and thus our skin and sinuses are dry and we are always in need of replenishing the lost water. Indoor environments in the winter are generally very dry in northern countries and so there is a need to add vapor so that we feel and function better. All land based animals have similar problems with the relative humidity around them. In fact just about all material both living and inanimate is affected by the amount of vapor in the air. Paint, plastics, silicone, paper, textiles etc.; Many manufacturing processes require close humidity and temperature control in order to maintain product quality. Indoor air quality (Health, Comfort and Productivity) - Material protection and storage - museums, archives, libraries, wood/paper, textiles, food processing Environments for specific processes - schools, health care facilities, offices, living space Printing, clean rooms, pharmaceuticals, laboratories, semiconductors Animal rooms/research, Zoological facilities Static electricity - computer rooms, data processing areas, hazardous environments, munitions, aerospace, paint spray booths 2008 ASHRAE, HVAC Systems & Equipment, Chapter 21 By E.M. Sterling, A. Arundel, and T.D. Sterling, Ph.D. Museums / Libraries 35-50%RH Offices / Hotels / Schools 35-40% RH Clean rooms / Data Centers Pharmaceuticals / Labs 35-60% RH 40-50% RH Hospitals / Health Care Printing Industry Tobacco Industry 35-50% RH 40-50% RH 60-70% RH Design Conditions - Outside temperature/RH(%) and desired indoor conditions Load calculation (lbs/hr) for ventilation system - Natural: Space/Room Size/Number of air changes Mechanical: Total Air Flow and % of outside air Economizer: Total Air Flow and Mixed Air Temperature Distribution - Airflow direction, AHU/Duct size and Absorption Distance Self contained • Supply water quality – City or well, softened, reverse osmosis or de-ionized • Energy source – Electricity, natural or LP gas, boiler steam or chemical-free boiler steam, High temperature hot water, Evaporative/atomizing OTHER PARAMETERS TO CONSIDER – – – – – – Initial investment Energy cost comparison Space available Steam distribution configurations Maintenance requirements Vapor barriers Description: Water is considered a universal solvent. In drinking water there are several minerals that are dissolved. Hardness is determined by the concentration of calcium and magnesium dissolved in water (ppm). Montreal city water 116ppm Precipitate: When water evaporates, the minerals create deposits. Water Treatment: water softeners, reverse osmosis or de-ionized systems Isothermal • Electric Humidifier • • • • • Adiabatic: • • Resistive Electrode Gas-Fired Humidifier Steam to Steam Humidifier Direct Steam Injection Humidifier • Multi-Steam Distribution • Jacketed Tube Distribution Atomizing Humidifier • • • Air/Water Fogger High pressure Water Ultrasonic Humidifier Evaporative Humidifier Isothermal Humidifiers Pros Cons Clean sterile steam Cost of energy Compact size Creates a certain cooling load Low installed cost Limited capacity Close humidity control If electric generation is close, very efficient Resistive type Pros Electrode type Pros Permanent cleanable chamber Works in all water qualities Output can be held very close Cons Required tank cleaning can be difficult Bottle change out is easy and fast Cons Replacement bottles are expensive Complicated control system wastes too much water Capacity loss as electrodes becomes coated, unit will stop Water quality affects operation and operating cost Bottles are not enviromentally friendly Pros Cons Clean sterile steam Large foot print Large capacity available Low energy cost Installation requirements (flue /combustion air) Close control Creates a cooling load 80-85% efficient Must have gas supply Not good for small loads Pros Cons Clean sterile steam Must have a central steam supply Large capacity Large foot print Closes boiler loop Creates a cooling load Can be difficult to maintain Pros Cons Large capacity Must have a central steam supply Low initial installation cost Home run steam / condensate Close control Chemical carry over / dirty Open loop for boiler Must keep the steam jacket hot Creates a cooling load Configurations Multi-Steam Distribution Consists of vertical tubes connected to a header Short non-wetting distance Jacketed Tube Steam Distribution Jacket preheats the steam distributor tubes Horizontal distributor installation only Steam nozzles facing the airstream Adiabatic Humidifiers Adding moisture to air can be accomplished with no addition of energy from external source. The air evaporates the water by itself, using a part of its sensible heat to accomplish the task, cooling the air as it absorbs moisture. Isothermal Humidification Adiabatic Humidification As the air absorb moisture and moves up the wet bulb line, the RH and the air temperature are both changing, but the total heat content (enthalpy) remains unchanged. This natural phenomenon is used to save energy costs by augmenting mechanical refrigeration in warm, arid climates. Buildings are cooled and humidified simultaneously using this principle. It is also used in cold climate when humidification is needed in buildings that have surplus internal heat from equipment or electronic gear. Pros Cons • • • • • • • • • • • • • • Evaporative cooling Small droplet size Very large capacity Can be put directly in space Long nozzle life Low maintenance Fully modulating Requires high inlet temp Long absorption distance Wetting of duct/standing water Potential for bacteria growth Particulate deposits/dust Pure water preferred Air compressor cost/kWh cost Pros • No air compressor Cons • • • • • Large droplet size Very long absorption distance Short nozzle life High maintenance On/Off or staged control only Pros • Compact size • Small water droplet size Cons • High initial cost • Must have ultrapure water supply Pros Very low power consumption Potable or pure water Low initial cost Cleanable, low maintenance No standing water in duct Cons Duct pressure drop On/Off or staged control Not good for close humidity control