Confined Space Entry

Confined Space

Entry

Agenda

• Introduction and Objectives

• Corporate Policy

• Requirements - WorkSafeBC

Regulations

• Classification of Confined Spaces

• Hazard Identification & Risk

Assessment

Agenda

• Confined Space Hazards

• Atmospheric Testing

• Ventilation

• Isolation & Lockout

• Rescue

• General Procedures

Training Objectives

• Upon completion of this course attendees will:

• Be familiar with the WorkSafeBC requirements and regulation

• Know their duties and responsibilities

• Understand the types of confined space hazards

Training Objectives

• Objectives

- continued

• Know the types of control measures used to ensure a space is safe

• Be able to conduct a pre-entry assessment

• Understand procedures for working inside a confined space

Training Objectives

• Objectives – continued

• Be familiar with the operation of gas detectors

• Be able to conduct atmospheric testing

• Know what to do in the event of an emergency

Corporate Policy

• Insert your corporate confined space policy information here

Regulatory Requirements

WorkSafeBC Regulations

WorkSafeBC Regulations

• Confined Space Entry - Part 9

• 9.2 - 9.5 - General Requirements

• 9.6 - 9.8 - Responsibilities

• 9.9 – 9.11 - Hazard Assessment and Work

Procedures

WorkSafeBC Regulations

• 9.12 - 9.16 - Identification and Entry

Permits

• 9.17 - 9.23 - Lockout & Isolation

• 9.24 - 9.26 - Verification and Testing

• 9.27 - 9.29 - Cleaning, Purging, Venting,

Inerting

WorkSafeBC Regulations

• 9.30 - 9.33 - Ventilation

• 9.34 - 9.36 - Standby Persons

• 9.37 - 9.41 - Rescue

• 9.42 - 9.45 - Lifelines, Harnesses & Lifting

Equipment

• 9.46 - 9.51 - Personal Protective Eqpt &

Other Precautions

Responsibilities

• The employer

• must have a written confined space entry program

• must assign overall responsibility for administration of the confined space entry program to a qualified person or persons

Responsibilities

• Supervisors

• Ensure that:

• pre-entry testing and inspections are conducted

• precautions are followed

• only authorized workers enter a confined space

Responsibilities

• Workers

must be instructed and trained in:

• the hazards of confined spaces

• the precautions identified in written procedures

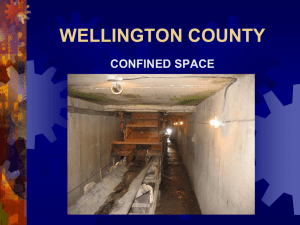

What Is a Confined Space

What Is A Confined Space

• A confined space is an area, other than an underground working, that:

1.

Is enclosed or partially enclosed,

2.

Is not designed or intended for continuous human occupancy,

What Is A Confined Space

• A confined space

- continued

3.

Has limited or restricted means for entry or exit that may complicate the provision of first aid evacuation, rescue or other emergency response service, and

4.

Is large enough and so configured that a worker could enter to perform assigned work.

What Is An Enclosed Space

• Has many of the characteristics of a confined space but does not meet the complete definition.

• may be as hazardous as a confined space and may require written procedures for entry.

What Is A Confined Space

• Review Confined Space Identification

Chart

Identification and Hazard

Assessments

Regulation 9.9 – 9.16

Identification and Hazard

Assessments

• Initial hazard assessments:

• identify confined spaces

• provide an initial classification of the spaces

• aid in maintaining the confined space inventory

• must be completed by a qualified person

Identification and Hazard

Assessments

• Classification is based on atmospheric hazards

• There are three classifications:

• Low Hazard Atmosphere

• Moderate Hazard Atmosphere

• High Hazard Atmosphere

Identification and Hazard

Assessments

• Low Hazard Atmosphere

• Contains clean respirable air (same as outside air) according to immediate preentry testing

• Air quality is not likely to change during the work activity, and

• Work will not generate contaminants

Identification and Hazard

Assessments

• Moderate Hazard Atmosphere

• Does not contain clean respirable air, but

• Any contaminants in the air are not likely to impair the ability of the worker to escape unaided from the space in the event of a failure of the ventilation system or respirator

Identification and Hazard

Assessments

• Moderate Hazard Atmosphere

- continued

• Work activity may generate air contaminants

• Contaminants are controlled

• Worker exposure to the contaminant(s) is not likely to impair the ability of the worker to escape unaided from the space in the event of a failure of the ventilation system or respirator

Identification and Hazard

Assessments

• High Hazard Atmosphere

• may expose a worker to risk of death, incapacitation, injury, acute illness or

• otherwise impair the ability of the worker to escape unaided from a confined space, in the event of a failure of the ventilation system or respirator

Identification and Hazard

Assessments

• A space may change between entries due to:

• Varying atmospheric conditions

• Changing hazard status

• Identification of new hazards

• Changes to access and ventilation

Identification and Hazard

Assessments

• Pre-Entry Risk Assessments:

• identify any changes that may have taken place in the confined space since last entry

• act as a permit

• provide procedural information

Identification and Hazard

Assessments

• Therefore, a pre-entry risk assessment

MUST be done prior to every entry

Identification and Hazard

Assessments

• Review the Preliminary Assessment

Flow Chart from the written program.

Confined Space Hazards

Confined Space Hazards

• Two categories of confined space hazards:

1.

Atmospheric hazards

2.

Physical hazards

Confined Space Hazards

• Major Causes of Accidents In Confined

Spaces:

• Entering without testing

• Using air purifying respirators in oxygen deficient atmosphere

• Re-entering the space without testing

Confined Space Hazards

• Major Causes of Accidents in Confined

Spaces

- continued

• Toxic vapours, gases or dust concentrations

• Flammable Gases, Vapours or Dust

• Oxygen Deficiency

• Electric Shock

Confined Space Hazards

• Why Do People Die In Confined

Spaces? They:

• do not recognize a confined space when they see one

• trust their senses

• underestimate the danger

• do not stay alert

• try to rescue other people

Confined Space Hazards

• Atmospheric Hazards

• The most common hazard and the leading cause of fatalities. They include:

• Toxic gases, vapours, dusts, mists

• Oxygen deficient (or enriched)

• Flammable / Combustible / Explosive

Confined Space Hazards

Atmospheric Hazards

Oxygen Deficient or

Enriched Atmosphere

O

2

Enriched

23 %

20 . 9%

Normal O

2 content in air

19 . 5%

O

2

Deficient

Minimum for safe entry

16 % Impaired judgement

& breathing

14 %

8 %

Faulty judgement

Rapid fatigue

Difficult breathing

Death in minutes

Confined Space Hazards

• Air contaminants and/or oxygen deficiency in confined spaces can be produced from:

• Normal processes

• Waste materials

• Work within the confined space

• Sources outside the confined space

Confined Space Hazards

• Hydrogen Sulfide (H

2

S) Gas effects:

• 1 ppm - you can smell it

• 10 ppm - 8 hour TWA

• 15 ppm - 15 minute STEL

• 100 ppm - Loss of smell

• 300 ppm - Loss of consciousness (approx. 30 minutes)

• 1000 ppm - Immediate respiratory arrest, loss of consciousness, followed by death (paralyses the

Phrenic nerve which controls breathing)

Confined Space Hazards

In one third of accidents involving toxic gas or oxygen deficiency, the danger was not present in the confined space at the time of the initial entry.

Confined Space Hazards

• Fire and Explosion Hazards

• The second leading cause of fatalities

• Two primary hazards:

• Flammable vapours – lead to explosions

• Inhalation risks – due to exposure to flammable vapours

Confined Space Hazards

Confined Space Hazards

• Fire and Explosion Hazards

• Flammable or combustible substances that may be found in confined spaces include:

• Flammable Gases

• Flammable Liquids

• Combustible Liquids

• Reactive Flammable Materials

Confined Space Hazards

Upper and Lower Explosive Limits (UEL/LEL)

Confined Space Hazards

• Sources of Ignition

• Open flame

• Hot work, e.g. welding

• Flammable and combustible substances

• Discharge of static electricity

Confined Space Hazards

• Eliminate Fuel Sources Prior to Entry

• The LEL must be maintained below 20%

• Clean out flammable residues prior to entry

• Use nonflammable cleaning solvents

Confined Space Hazards

• Keep cylinders outside of the space

• Check hoses and nozzles for leakage before use

• Remove torches & hose assemblies when not in use

Confined Space Hazards

• Static Electricity

• Caused by friction between two moving substances or objects

• Includes the pouring of liquids and powdered solids

• More severe in cold weather

• Can be eliminated by grounding and bonding

Confined Space Hazards

• Physical Hazards may include:

• Toxic Materials

• Falling

• Engulfment

• Falling Objects

• Noise

• Temperature

Extremes

• Slick/Wet Surfaces

• Machinery

• Mechanical

Equipment

• Electric shock

• Poor visibility

Confined Space Hazards

• Control of Physical Ha

zards

• If entry is necessary:

• Inspect the structure through inspection ports where possible

• Use mechanical means to dislodge bridges and hung up material

Confined Space Hazards

• If Entry Is Necessary, ensure that:

• equipment in space is de-energized and locked out prior to entry

• entry workers wear lifeline and harness and are attended by a standby worker

• entry workers are provided with any other necessary protective equipment

Confined Space Entry

Equipment

Entry Equipment

• Entry equipment may include:

• Gas detectors (Atmospheric Testing)

• Personal Protective Equipment (PPE)

• Footwear

• Gloves

• Hardhat

• Coveralls

Entry Equipment

• Entry equipment may include

- continued

• Respiratory protection

• Ventilation equipment

• Lighting

• Entry Forms

• Rescue / Retrieval equipment

Isolation and Lockout

Regulation 9.17 – 9.23

Isolation and Lockout

• Energy Sources include:

• Electrical

• Pressure

• Momentum / Gravity

• Residual / Stored Energy

Isolation and Lockout

• Blanking and Blinding:

• Must be certified

• Other precautions

• Specific written work procedure

Isolation and Lockout

• Lockout Procedure Summary

• All Entrants must have their own locks and the only key to their lock

• Before turning off the power, ensure no one is operating the machinery

• All lines must be bled, drained or cleaned out

Isolation and Lockout

• Lockout Procedure Summary – continued

• All mechanisms under pressure or tension must be released and blocked

• Every person working on the machinery must put his/her own lock on

• All energy sources to machinery must be locked out

Isolation and Lockout

• Lockout Procedure Summary

- continued

• Use safety blocks and pins to support machinery that could fall

• All workers using locks must be trained in lockout procedures.

Verification and Testing

Regulation 9.24 – 9.26

Verification and Testing

• Test all confined spaces prior to initial entry

• Testing must be done no more than 20 minutes prior to any entry

• Record test results at least every 20 minutes

Verification and Testing

• Test at all levels of the space

• Testing prior to re-entry if the space is vacated 20 minutes or more

• Vacate immediately if alarm sounds

Verification and Testing

• The atmosphere must be monitored continuously while workers are in the confined space

Verification and Testing

• Testing order

1.

Test for Oxygen first

2.

Explosive condition

3.

Toxicity levels of contaminants that may be in the space

Verification and Testing

• Air Testing Procedure

1.

Warm up detector

2.

Zero detector

3.

Test air above opening to space

4.

Test air in space before and after ventilating

5.

occupied

Verification and Testing

• Additional air monitoring must be done

• If space is vacated and out of visual site of workers for any length of time

• Any time space is vacated for 20 minutes or more

• After any unusual occurrence such as strange odours

• After any interruption of mechanical ventilation

Ventilation

Regulation 9.30 – 9.33

Ventilation

• Mechanical ventilation

• Mandatory for all entries

• Must be continuous and commence at least 10 minutes prior to entry

• Blows air into the space

• Must provide 50 cfm of fresh air per worker in the space

• Not a substitute for air monitoring

Ventilation

• Replaces contaminated air with clean, breathable air

• Decreases the chance of an explosion

• Eliminates toxicity

• Increases the chance of survival

• Creates cooling effect for both victims and rescuers

Ventilation

• Local Exhaust Ventilation

• Required in some instances

• Natural Ventilation

• Must be sufficient to maintain any contaminants below their exposure limits

Ventilation Precautions

• Minimize bends and kinks in the hose

• Position the blower so it is clear of vehicle exhaust and other sources of pollution

• Place compressor upwind of the entrance

Ventilation Precautions

(cont’d)

• Ensure compressor cannot be shut off without knowledge of entry personnel

• Purge blower by directing flow of air at street level, away from the open manhole

Ventilation Precautions

(cont’d)

• Ventilate for several minutes prior to entry

• If ventilation system fails leave the space immediately

• Locate discharge end of hose 2 feet from the bottom of the space

Ventilation Precautions

(cont’d)

• Use explosion-proof fans

• If flammable atmospheres may be present, bond ventilation equipment to confined space structures made of metal

• Do not locate air inlets close to outlets

Ventilation

Ventilation

Standby Persons

Regulation 9.34 – 9.36

Standby Persons

Low Hazard Atmospheres

• Entrants Must:

• have continuous means of summoning the standby person

• The Standby Person Must:

• check on the well-being of entrants at least every 20 minutes

• have means of summoning rescue personnel

Standby Persons

Moderate Hazard Atmospheres

• Entrants must:

• have continuous means of summoning the standby person

Standby Persons

Moderate Hazard Atmosphere

• The Standby Person Must:

• be stationed at or near entrance to space

• visually observe or otherwise check wellbeing of the entrants at least every 20 minutes or more if required

• have means of summoning rescue personnel

Standby Persons

High Hazard Atmospheres

• Entrants must:

• have continuous means of summoning the standby person

Standby Persons

High Hazard Atmosphere

• The Standby Person Must:

• be stationed at the entrance to the space

• continuously monitor the well-being of the entrants

• be equipped and capable of immediately commencing rescue of workers in the space

Rescue and Emergency

Regulation 9.37 – 9.41

Rescue and Emergency

• Emergency rescue procedures and rescue plans must be

• in place before entry

• reviewed at a pre-job planning discussion

Rescue and Emergency

• Rescue equipment must be located on site and users must be trained in its use.

Rescue and Emergency

• Retrieval Systems include:

• Tripod

• Pulley

• Retrieval line

Rescue and Emergency

• Rescue equipment must be:

• Maintained

• Inspected

• Records kept

Rescue and Emergency

• Rescue equipment may include:

• Respiratory equipment (SCBA or SAR)

• First aid equipment

• Communications equipment

• Full body harnesses

Rescue and Emergency

• Rescue equipment

- continued

• Lifelines

• Worker lift device / system

• Fall protection

• SKED or similar equipment

Rescue and Emergency

• Four Safe Rescue Practices

1.

Rescue from outside whenever possible

2.

Enter to rescue only after help arrives

3.

Enter only with use of a safety harness and lifeline

4.

If a harmful atmosphere is possible, assume it is IDLH and enter only with

SCBA or air supplied respirator

Summary

General Requirements

• For All Confined Space Entry

1.

All workers involved must be trained and must know, understand and follow procedures

2.

The Standby Person will remain by the opening whenever a worker is in the space

General Requirements (cont’d)

3.

Wear proper clothing and PPE

4.

Keep the entrance to the space clear

5.

Do not throw anything into the space

6.

Use explosion proof or intrinsic equipment when risk of flammable atmosphere exists

7.

Do not take compressed gas cylinders into the space

General Requirements (cont’d)

8.

Inspect compressed gas hoses prior to use and remove when not in use

9.

Have specific written procedures for hot work

10.

Have an MSDS on site for hazardous materials that are used

General Requirements (cont’d)

11.

Workers will vacate the space whenever:

• A worker notices an unusual odour, taste or sensation

• The gas detector alarm sounds

• The standby person tells entrants to leave the space

• The mechanical ventilation stops working

• Entrant loses communication with standby person

Questions