Slide 1

advertisement

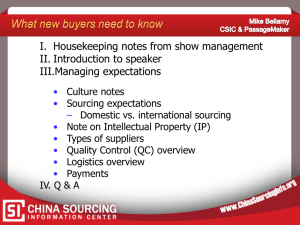

Chapter Global Sourcing Strategy Key Points International Product Cycle Theory Trends in Global Sourcing Strategy Potential Pitfalls in Global Sourcing The Value Chain Functional Interfaces Logistics of Sourcing Strategy Long-term Consequences 5 International Product Cycle Theory Global competition suggests a drastically shortened life cycle for most products, and no longer permits companies a polycentric, country-by-country approach to international business. A frequently used framework to describe cross-national business practices is the international product cycle theory. International Product Cycle Theory According to the theory, changes in inputs and product characteristics toward standardization over time determine an optimal production location at any particular phase of the product’s life cycle. International Product Cycle Theory (cont.) However, three major limitations of the international product cycle theory have to be borne in mind: 1.Increased pace of new product introduction and reduction in innovational lead time, which deprive companies of the age-old polycentric approach to global markets Innovations can make the “global market” perspective wrong International Product Cycle Theory (cont.) However, three major limitations of the international product cycle theory have to be borne in mind: 2.Predictable sourcing development during the product cycle, which permits a shrewd company to outmaneuver competition Stable inputs may allow for cost savings International Product Cycle Theory (cont.) However, three major limitations of the international product cycle theory have to be borne in mind: 3.More active management of locational and corporate resources on a global basis, which gives a company a preemptive first-mover advantage over competition. Assumes management matters International Product Cycle Theory (cont.) Emphasis on logistical management of the interfaces of R&D, manufacturing, and marketing activities on a global basis – global sourcing strategy Balance between drive for cost savings (standardization) and customization needed The reality of global business is that the product life-cycle is not as predictable and stable as it once was Trends in Global Sourcing Strategy Trend 1: The Decline of the Exchange Rate Determinism of Sourcing Foreign sourcing occurs for non-cost reasons – i.e. access to technology Difficulty of dropping overseas suppliers Domestic suppliers may increase prices when they know their customers don’t have a choice Long-term relationships tend to survive exchange rate fluctuations Portfolio perspective of foreign operations Trends in Global Sourcing Strategy Trend 2: New Competitive Environment Caused by Excess Worldwide Capacity Price, quantity and delivery now not so uncommon or important as are quality and uniqueness which lead to higher price expectations weakening FX concerns Trends in Global Sourcing Strategy Trend 3: Innovations in and Restructuring of International Trade Infrastructure More experienced purchasing managers Improvements in transportation and communication Finance availability and options Global diffusion of manufacturing Neighbouring country sourcing opportunities Trends in Global Sourcing Strategy Trend 4: Enhanced Role of Purchasing Managers Purchasing now considered strategic more of a role and resources to do their job better will still get lowest cost/highest quality regardless of FX fluctuations JIT production so ingrained into production processes that stores of inventory no longer held requires constant influx of raw materials to keep business operating Trends in Global Sourcing Strategy Trend 5: Trend toward Global Manufacturing Globally dispersed facilities mean firms have no choice but to continue with global sourcing regardless of FX fluctuations Potential Pitfalls in Global Sourcing Conflict between unification and fragmentation - a close-knit operational strategy with similar foreign units versus a loosely related, highly variegated family of activities. Diverse activities are still inhibitors rather than facilitators of cost savings Potential Pitfalls in Global Sourcing Dilemma revisited in such terms as: “standardization versus adaptation” (1960s) “globalization versus localization” (1970s) “global integration versus local responsiveness” (1980s) “scale versus sensitivity” (1990s) However, ability and willingness of companies to integrate have changed due to competitive urgency. The Value Chain The collection of activities that are performed by a company to design, manufacture, market, deliver, and support its product is called the value chain. The Value Chain The value chain can be divided into two major activities performed by a company: (1) primary activities consisting of inbound logistics (procurement of raw materials and components), manufacturing operations, outbound logistics (distribution), sales, and after-sale service, and (2) support activities consisting of human resource management, technology development, and other activities that help promote primary activities. The Value Chain (cont.) Five continuous and interactive steps are involved in developing such a global sourcing strategy along the value chain. 1. Identify the separable links (R&D, manufacturing, and marketing) in the company’s value chain 2. In the context of those links, determine the location of the company’s competitive advantages, considering both economies of scale and scope The Value Chain (cont.) 3. Ascertain the level of transaction costs between links in the value chain, both internal and external, and selecting the lowest cost mode 4. Determine the comparative advantages of countries (including the company’s home country) relative to each link in the value chain and to the relevant transaction costs 5. Develop adequate flexibility in corporate decision making and organizational design so as to permit the company to respond to changes in both its competitive advantages and the comparative advantages of countries. Functional Interfaces Management of the interfaces, or linkages, among these value-adding activities is a crucial determinant of a company’s competitive advantage. Functional Interfaces Global sourcing strategy encompasses management of The interfaces among R&D, manufacturing, and marketing on a global basis and Logistics identifying which production units will serve which particular markets and how components will be supplied for production. R&D/Manufacturing Interface Manufacturing/Marketing Interface Marketing/R&D Interface Logistics of Sourcing Strategy “Sourcing” is used to describe the management by multinational companies of the flow of components and finished products in serving foreign markets. Intrafirm Sourcing. Multinational companies procure their components in-house within their corporate system around the world. Domestic in-house sourcing. Offshore subsidiary sourcing. Logistics of Sourcing Strategy Outsourcing. Component procurement from overseas (offshore subsidiary sourcing and offshore outsourcing) has been a serious social and economic issue as it affects domestic employment and economic structure. Long-term Consequences Two opposing views of the consequences of offshore outsourcing: Strategic Alliances Maximizes specialized competences Dependence Creates uncertain environment for independent suppliers, increasing production and material costs.