Vacuum Truck Operations

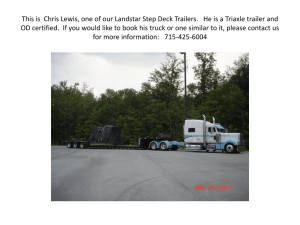

advertisement

VACUUM TRUCK OPERATIONS CAER Safety Summit – June 2012 GULF COAST FATALITY – INCIDENT LEARNINGS 2007 a Vacuum Truck Helper was Exposed to H2S Vapors due to Incompatible Materials Reacting Inside the Vacuum Truck. • The Truck was Drained, but not Cleaned, after Recovering Material from a Previous Chemical Cleaning Job. • Established Procedures Must Be Followed and Reinforced •The Work Permit did not Include Vacuuming Material from the Secondary Containment (Which Contained Acid) • Work Permits Must Be Specific and Must Be Followed • The Vacuum Truck Company added a Second Truck to the Job, without contacting Operations • All Personnel who Sign-on a Permit Must Read and Understand it AND Proposed Changes Must be Approved by Operations. • The Vacuum Truck Operator and Helper did not Properly Respond to the PHM Alarms by Immediately Leaving the Area • All Personnel Must Evacuate the Work Area without Exception VACUUM TRUCK BASIC PRINCIPLES OF OPERATION Training and Awareness Clean Tanks and Vacuum Pumps Product Identification Mixing of Materials – Not Allowed Static Electricity Management Control of Vacuum Pump Vapors Personal H2S Alarm Actions Defined and Controlled Offloading TRAINING AND AWARENESS Contract Vacuum Truck Operators must be trained: • API Recommended Practice 2219 for Safe Operation of Vacuum Trucks in Petroleum Service • Their Company Specific Vacuum Truck Procedures • Loading, Unloading, Venting, Bonding/Grounding, Continuity Checks, Scrubbers, etc • HAZWOPER Certified Workers working with vacuum truck operators (Plant Operators, Mechanics, Supervisors, etc) must have Awareness training in the principles of Safe Vacuum Truck Operations. • Unit Operators must be specifically trained to be familiar with the Vacuum Truck Checklist and the Offloading Matrix. Vacuum Truck Checklist • All Vacuum Trucks Loaded and/or Unloaded must have a completed Refinery Vacuum Truck Checklist. • • • • • Date – Driver - Company Identify Material to be Loaded Verify Clean Tank & Pump Scrubbing System Needed? Loading & Offloading Locations • • • • • Designated Location Operator Signatures Permits Needed Bonding & Grounding Positioning & Venting • Electrical Continuity Verified • Hard Connections < 15 psi CLEAN TANKS AND VACUUM PUMPS To Prevent Possible Harmful Chemical Reactions: The tank and pump must be cleaned after each load, except: 1. When Returning to the Same Location to Load the Same Material, or 2. When Performing a Repetitive Job Order with Known MaterialsCharacteristics (typically Hydrocarbon on Hydrocarbon) e.g. Slops Barrels Pick-up Runs Vacuum Trucks are cleaned at the End of Each Day to Prevent the Possibility of a Dirty Truck being used on an After-Hours Callout. Note: Any Truck Left Dirty Must Have its Keys Locked in a Lock Box that is Only Accessible by a Maintenance Supervisor and a Form Must be Completed Describing the Material Last Loaded. PRODUCT IDENTIFICATION All Materials Loaded onto a Vacuum Truck must be Positively Identified. The Operator or Equipment Owner is Responsible to Positively Identify the Material to be Loaded and the Properties of the Material. •Flammable or Combustible •H2S or Other Toxic Characteristics •Corrosive Material MIXING OF MATERIALS NOT ALLOWED Materials May Not Be Mixed! Exception is Hydrocarbon on Hydrocarbon with a Repetitive Job Order • These Jobs are Done Several Times per week from Designated Pick-up Locations • Materials are Similar and Compatible STATIC ELECTRICITY MANAGEMENT • Vacuum Truck Hoses Undergo Continuity Checks and Scheduled Inspections • Each Time a Vacuum Truck is Loaded the Vacuum Hose and Grounding Wire are Checked for Electrical Continuity • Plastic Containers Are Not Used to Catch Flammable or Combustible Liquids CONTROL OF VACUUM PUMP VAPORS • Gasoline Range Materials Must Be Loaded by Alternative Means: • Butanes and Similar Materials are Not Loaded • Light Hydrocarbons May be Pumped (BY USE OF A POSITIVE DISPLACEMENT PUMP) onto the Truck, or • Prior to Loading a Vacuum Can be Established to Draw the Material onto the Truck without Running the Pump • Caustic Scrubbers are Used to Reduce H2S Emissions • Vacuum Pump Hoses are Extended At Least 50’ to a Safe Location to Prevent Fire or Harmful Exposure to Personnel PERSONAL H2S ALARM ACTIONS • Any Job Requiring Vacuum Truck Operators to Wear Fresh Air Must Have a Specific Procedure • Virtually Never Done - Alternative Means Are Used • All Vacuum Truck Operators / Helpers Must Wear a PHM • All Plant Workers Must Wear PHMs, it is Emphasized for Vacuum Truck Operators • All Vacuum Truck Operators / Helpers Must be Aware of What Actions to Take in the Event of a PHM Alarm • All Personnel Must Be Aware of Actions to Take, it is Emphasized with Vacuum Truck Operators DEFINED AND CONTROLLED OFFLOADING All Materials Loaded onto a Vacuum Truck Must have a Designated Offloading Location Prior to Loading. The Operator or Equipment Owner is Responsible to Designate the Offloading Location According to a PreIdentified Offloading Matrix to Ensure Material Compatibility Questions