COPELANDS - Judith Mallon

advertisement

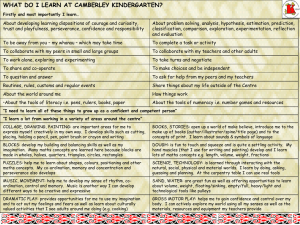

STEM WORK PLACEMENT 1ST June to 4th June 2009 Copeland, Cookstown Judith Mallon- Maths Teacher St Joseph’s College, Coalisland The Company Copeland Ltd is part of an American company called Emerson Climate Technologies. Emerson are the worlds’ leading provider of: – – – – – Heating Ventilation Air Conditioning Refrigeration Oil and Gas Copeland started production in 1997. They make compressors which are used in refrigeration, air conditioning and, more recently, heat pumps. At present they make up to 1500 compressors per day. They started off with 100 per day! The reason for their success in this market is the use of Scrolls inside their compressors. Most other companies use pistons These Scrolls and their production are top secret! They are made behind “the wall” Some employees never get behind the wall and those who work there have to sign a confidentiality agreement. I was lucky enough to get a tour behind the wall! Here is a picture of “the wall”. I wasn’t allowed to take any pictures behind it. In my placement, I shadowed employees on their day-to-day duties. I discovered how they used Maths in their job and where using and applying Maths in the workplace can be linked to my Schemes of Work. I worked with Engineers, Production Supervisors, Business Improvement Facilitators, IT Technicians, Quality Managers and Human Resource Managers. I met lots of interesting people. One employee, Eugene Corr, is a past pupil of St Joseph’s College. He has worked in Copeland Ltd for 11 years. Eugene completed a HND, Degree and is now in his final few weeks of completing a Masters Degree from The University of Ulster, Jordanstown. Copeland Ltd offered him this opportunity to continue his professional development due to his enthusiasm and hard- work. He did all this alongside his fulltime employment. Here is a picture of Eugene. Another employee is Tom McQuaid. Tom is a Business Improvement Facilitator. This means he facilitates and oversees business improvement initiatives. His job resembles a teacher’s job. He is always trying to find ways to make improvements and minimise errors through group work and problem solving. He certainly gave me some ideas that I can bring back to the classroom and implement in my teaching. Here is a picture of Tom. To do this work effectively everyone needs understanding of Maths. a basic For example: mentally add and subtract positive and negative decimal numbers. Target-setting and reporting back are done through bar charts, scatter graphs, box plots, mean and standard deviation. Measurements used include volume, conversion between metric and imperial units and trigonometry. Problem solving is another key aspect that features strongly The employees on the shop floor need to be able to in the day to day running of the company. In terms of softer skills and qualities, an employee needs to be a team player. Every department is linked and someone is always relying on someone else to get the job done successfully. Co-operation, communication, enthusiasm and adaptability feature strongly alongside punctuality, attendance and willingness to take and give direction. I intend to encourage my pupils to achieve these skills and qualities by incorporating them into my lesson plans and classroom activities. I plan to introduce a more practical aspect to some of my lessons e.g finding volumes of boxes. Group work is another method I mean to use more of and is highly relevant to the Maths curriculum. I have seen its benefits in terms of employability through this placement. Everyone wears the same uniform right to the plant manager. This seems to give all employees a sense of equality and importance. Although the type of work was very different to what I do each day, I also found a lot of similarities between the running of this company and that of my school. Everyone works together to maximise production, minimise waste and hence achieve the best possible results, just like a school. The ages of the workforce ranged from 18 to approximately 50, although there were a few employees over 50. There are around 200 employees made up of approximately 70% males and 30% females. I did notice that the Engineers and Production Supervisors were primarily male. Here are a few pictures of people at work, including myself. Catherine and Monica in Final Assembly Part of the manufacturing line Compressors ready to be shipped Packaging More compressors ready to be collected and shipped Barry and Myself in Helium Operation Lisa and Ashleigh in Human Resources The top secret “Scroll” Although I had a brilliant placement, I love my job as a teacher so I wouldn’t change permanently to what I did all week. However it gave me an invaluable insight into the working environment and the employability skills that we, as teachers, need to convey to our pupils. I plan to stress to my pupils the importance of Maths in every aspect of the working day and show them how it is relevant to their future employment. I cannot emphasise enough how showing enthusiasm for your job can result in great rewards and opportunities such as further education and development thus leading to promotion and hence a pay rise!