OSHA/C-DAC Requirements for Riggers & Signal Persons

advertisement

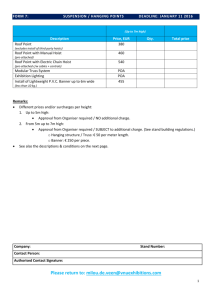

OSHA/C-DAC Requirements for Riggers & Signal Persons What you need to do to be in compliance with the new rules “Qualified Riggers” A qualified rigger is required during hoisting activities & whenever workers are in the fall zone. A qualified rigger must “possess a recognized degree, certificate, or professional standing, or has extensive knowledge, training,& experience, and can successfully demonstrate the ability to solve problems related to rigging loads.” Who determines if a rigger is “qualified”? OSHA says that the EMPLOYER has the responsibility to determine if a rigger is qualified. “Employers must determine whether a person is qualified to perform specific rigging tasks.” Qualification is limited to the individuals experience, knowledge and training. For example, a person who is qualified to rig structural steel, may not be qualified to rig mechanical equipment. What steps can you take to achieve compliance? Do an assessment of your employees to determine who has a rigging background, and to what degree are they qualified. Determine who in each work group you are comfortable with as one of YOUR “qualified riggers”. If that person/those people have not received formal rigging training, or cannot certify that training, arrange for a class. What do you look for when arranging a rigging training class? Always look for a trainer who will sit down and discuss your company & what you do. Discuss your concerns based on your experiences. Tell the trainer about any situations/problems that have occurred in the past. Be sure to make the trainer aware of all company policies that relate to rigging. For example, some companies do not use synthetic slings, while others may not use chains. How long is a training class, & where should they be done? A good rigging training class should last 4-5 hours. Asking a reputable trainer to cut that down to 2 hours is like telling your doctor to speed up that by-pass surgery. Classes should be done in a “classroom like” environment. Job trailers with telephones ringing & people coming in and out are not the best situation for training. Signal Person qualification requirement A signal person is required when “the point of operation is not in full view of the operator, &/or the operators view is obstructed in the direction the equipment is traveling , &/or either the operator or the person handling the load determines that a signal person is needed.” The employer must take steps to ensure that the signal person is qualified. What must a “qualified signal person” know? The person must know the standard hand & voice signals. The person must demonstrate their competence in using the standard hand & voice signals. They must understand the characteristics and limitations of the hoisting equipment. They must understand the newest standards for working with hoisting equipment near power lines. The person must pass either an oral or written test & a practical test. What is required for qualification as a “signal person”? Employers must use a “Third Party qualified evaluator” or they may use their own “qualified evaluator”. An “in house” evaluation is acceptable to OSHA, but may not be accepted by other employers. The person must receive training, be tested on the material, & be tested in the practical application of the material. OSHA says that the EMPLOYER has the responsibility to determine if a signal person is qualified. Requirement of proof for the qualified signal person “Employers must make the documentation of the signal person’s qualifications available at the worksite.” Each qualified signal person should carry a card that acts as proof of their qualifications. Persons who cannot supply proof of their qualification as a signal person, cannot perform signaling and are subject to fines if they do attempt to signal.