MP-I Manual_012110045303_1

advertisement

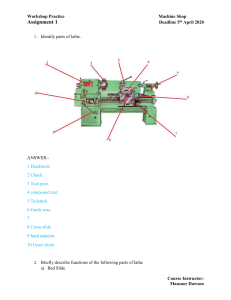

DEPARTMENT OF MECHANICAL ENGINEERING SEMESTER - III WORKSHOP PRACTICLS SESSION- 2009-10 SUBJECT: - MANUFACTURING PROCESSESS- I LIST OF EXPERIMENTS 1. Study of Single Point Cutting Tool. 2. Study of Mechanism in Lathe. 3. Practical on Lathe Machine. 4. Study of Mechanism in Milling Machine. 5. Study of Mechanism in Shaping Machine. 6. Study of Mechanism in Drilling Machine. Experiment No. 01 Aim: - Study of Single Point Cutting Tool 1.1 Introduction 1.2 Designation Of Cutting Tools (I) American Standards Association System (ASA) (II) Orthogonal Rake System (Ors) 1.3 Tool Geometry 1.4 Tool Signature 1.5 Cutting Tool Materials 1.6 Desirable Properties Of Cutting Tool Materials Experiment No. 02 Aim: - Study of Mechanism in Lathe 2.1 Introduction 2.2 Working Principle Of Lathe 2.3 Operations Performed On Lathe 2.4 Specification Of Lathe 2.5 Classification Of Lathe 2.6 Mechanisms In Lathe 2.6.1 Flow Of Power From Motor To Spindle 2.6.2 Methods Of Taper Turning 2.6.3 Thread Cutting On Lathe Experiment No. 03 Aim: - Practical On Lathe Machine (Job Description) Name of Shop Name of Job Raw Material Material Size Job Size Tools Required : - Machine Shop : - Turning, Threading and Knurling (JOB ON LATHE) : - M. S. Round Bar ::: - Single point cutting tool (HSS) , Parting-off tool, Knurling tool, Drill bit, Tap and tap wrench, Vernier caliper, Steel rule, V-threading tool, Threading gauges, marking block. Procedure:Sr. No. 01 Name of Operation Operation Performed Tools Used Holding and Truing Marking block and chuck key 02 Facing 03 Plain Turning 04 Step Turning 05 Drilling and Tapping 06 Threading 07 Grooving or Necking Take a raw material (m.s.round bar) clamp it in three jaw chuck from one end and true it from other end so that it should rotate along the centre of the chuck. Carry out facing operation on the free end of the shaft then reverse the end and carry out facing to maintain the required length with the help of HSS single point cutting tool. Turn the diameter to the maximum final job diameter through out the length. Make the steps of the required dimensions according to the given job sketch Fix drill chuck in tail stock , insert drill bit of required size and drill a hole at the centre of work piece from free end up to the depth given in the sketch and then perform taping operation with required size tap Engage the lead screw with the cross slide by operating lever of split nut, cut an external V- thread of size specified in the job drawing. Necking is done on unthreaded portion according to the job sketch Single point cutting tool Single point cutting tool Single point cutting tool Drill bit, Tap tool and Wrench V-threading tool Parting tool 08 Taper Turning 09 Knurling 10 Chamfering after threading Perform the taper turning operation by turning compound rest through the calculated angle Perform knurling operation on the portion shown in the sketch. The purpose of knurling is to provide effective gripping surface Chamfer the both ends of the job to avoid the handling hazard, in chamfering the sharp edges are beveled by the angle given in the sketch ( generally beveled by 450 ) Formula to be used to set taper angle of Compound Rest Tan θ = D – d / 2 l Where θ = Taper angle in degree D = Bigger diameter of work piece in mm d = Smaller diameter of work piece in mm And l = Length of work piece for taper turning in mm Single point cutting tool Knurling tool Single point cutting tool Experiment No. 04 Aim: - Study of Mechanism In Milling Machine 4.1 Introduction 4.2 Working Principle of Milling Machine 4.3 Types of Milling Machine 4.4 Specification of Milling Machines 4.5 Tool Geometry of Simple Milling Cutter 4.6 Operations Performed On Milling Machines Experiment No. 05 Aim: - Study of Mechanism In Shaping Machine 5.1 Introduction 5.2 Applications of Shaper 5.3 Working Principle of Shaper 5.4 Specification of Shaper 5.5 Types of Shaper 5.6 Quick Return Mechanisms In Shaper 5.6.1 Crank and Slotted Link Mechanism 5.6.2 Withworth Quick Return Mechanism 5.6.3 Hydraulic Mechanism Experiment No. 06 Aim: - Study Of Mechanism In Drilling Machine 6.1 Introduction 6.2 Types of Drilling Machine 6.3 Specification of Drilling Machine 6.4 Operations Performed On Drilling Machine 6.5 Tool Geometry of Simple Twist Drill References for All Experiments 1. Workshop Technology Vol. I & II - S. K. Hajara Choudhury - A. K. Hajara Choudhury & - Nirjhar Roy 2. Manufacturing Technology - R. K. Rajput 3. Production Technology - R. K. Rajput 4. Workshop Technology Vol. I & II -Raghuwanshi 5. Production Technology – HMT Precautions Precaution to be taken by the students while performing operations on the Lathe Machine Every student should follow all safety rules displayed separately in Machine Shop 1. Use of apron is compulsory 2. Sleeves should be rolled up and ring wrist watch, jewelry and neck tie etc. should be removed 3. The tools should never be placed over lathe ways or carriage 4. The chips should never be removed by hand, wire brush should be use for this purpose 5. The key should always be removed from the chuck before starting the machine