Maximo for Unit Facilities Organizations

advertisement

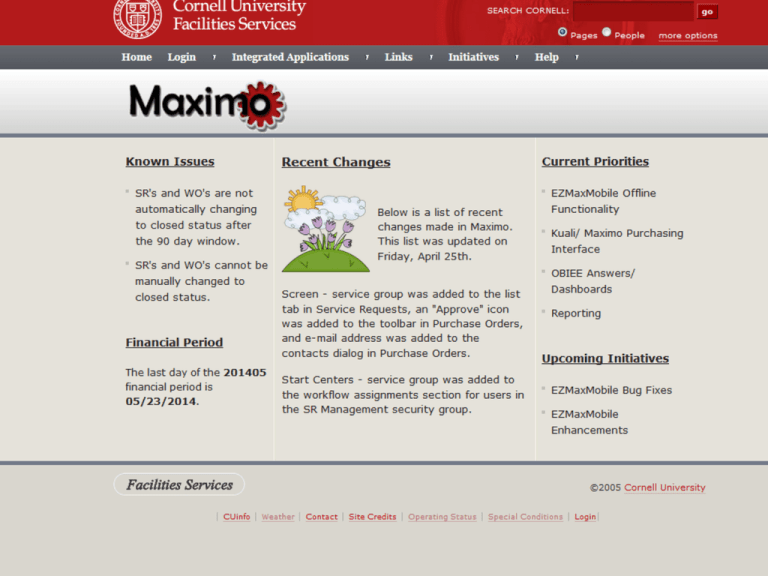

Summary Maximo is an Enterprise Asset Management System used by Cornell University Facilities Services. Many of Cornell's physical assets found across campus are tracked in Maximo, as well as scheduled and completed work, employee information, and costing information. - For certain assets, preventative maintenance work can be scheduled in Maximo. Work orders are generated at the time that it is scheduled. The work order describes the work to be done, and people are then assigned to the work order, depending on the craft that is needed to get the work done. - Work orders for corrective maintenance can also be scheduled in the Maximo system by creating a service request. Facilities Services also uses Maximo to track projects, project estimates, and jobs. - When material is needed for work, purchase requisitions requesting material can be created in Maximo. Purchase order(s) are then created and associated with the work order, in which information about the material, including the material cost(s), are added. The system also provides inventory management for those materials that are kept in stock at Cornell. - When work is completed, employees log the hours worked and a description of the work completed on the work order. Transactional data from Maximo is gathered during the monthly billing process and sent to Kuali processing. The next seven slides will describe in more detail the individual groups in the Facilities family that use Maximo directly and/or indirectly. They are: • • • • • • • Individual College Facilities units Grounds Contracts Capital Projects and Planning Utilities Maintenance Management Contract College Facilities You may proceed directly to the group that best describes your current area or review as many as you would like. Individual College Facilities Unit When the need for service or repair is requested by a specific unit, a service request is issued. This can be done via phone or electronically. In the latter case, information is entered via a website which interfaces with Maximo to create the service request. The service request process is designed to handle the routine/corrective maintenance and other daily facility needs of our campus community. The service request system provides a quick and easy mechanism to request work from Facilities Services, and works in conjunction with our Maximo System to handle customer billing and material procurement. This mechanism provides a trackable document with applicable information to accomplish needed work. Grounds receive Service Requests in Maximo on a daily basis. Work Orders are then assigned to the appropriate person, who then does the work. Charges are entered daily against the Work Orders, which includes labor and material. When the job is complete, the Work Order status is changed from “In Progress” to “Complete”. When material is needed from outside vendors, Purchase Orders are created against the Work Orders in Maximo. Facilities Contracts Facilities Contracts receive Work Orders to facilitate payments associated with contract related services. Work Orders created are a foundation for Maximo Purchase Order creation to bill customers for contract payment, printing and other related charges. When all payments are complete, the Purchase Order status is changed to "Closed" and the Work Order status is changed to “Complete”. Capital Projects & Planning (CP&P) enters Jobs and issues Work Orders to other units for project support services. CP&P provides Project Management services and utilizes the Jobs function in Maximo for project billing and budget oversight. Work orders created from the Jobs are used by CP&P staff to enter labor and provide a tracking mechanism for project budgets. Within CP&P, a specified user with access rights approves all labor. Labor transactions can be run as a report and reviewed. Utilities Work Orders are generated either automatically depending on the time or condition (Preventative Maintenance) or from someone in our department requesting work (Work Order module). For internal work, no Service Request is created (Shops work is created via Service Requests.) External service work (outside Cornell) is created via Purchase Orders in Maximo where applicable (non-contract). Some of the contract work is also captured for costing information. Internal labor is not “billed” so the system is used for reliability, efficiency, and later reference only. When Work Orders are received, they are first reviewed for accuracy/ content and categorized (mechanical/ technical/ operations/ engineering) by the maintenance planner. Internal Work Orders are assigned to the mechanical/ technical staff by the Maintenance Manager, depending on the craft that is needed. There is some overlap and mechanical staff can work on technical work orders and vice versa. Maintenance staff handles all their own work management electronically via Syclo, which is a mobile interface for Maximo. This includes entering hours, comments, retrieving attached documents, viewing LOTO info, completing assignments, etc. As needed, maintenance staff will create Purchase Requisitions for materials in Syclo. These can either be chosen from inventory records or free text descriptions. Materials are then ordered by the Maintenance Planner, and the entire record trail, which includes scanned packing slips and invoices, is kept in Maximo. Reminders and data analysis is handled via reporting in Maximo. Monthly, Weekly or daily automated reports are generated and emails are sent to necessary recipients. Some of these reports are: -Weekly labor details reports that shows us each person’s total hours per work order with the description of the work order and totals for the week -Work orders completed in the last 7 days (separate for each shop) -New work requests for the last 3 days by operations -Daily operations logs -Shops work orders work charged labor in the last 7 days Maintenance Management uses Maximo to track jobs that are requested by Maintenance Management. They track project costs versus allocated funds. Some jobs are entered into Maximo by Maintenance Management, in which case necessary Work Orders are also created. Data is pulled from Maximo to track Corrective, Preventive and Planned Maintenance costs by Facility, College or whatever breakdown is being looked at. When a destructive event such as a fire or flood occurs, details are pulled from Maximo and sent to Risk Management. Risk management uses this information to reimburse the University for any costs incurred by such an event. Maintenance Management also pulls data for many other reason as questions are asked. Contract Colleges Facilities (CCF) uses Maximo to create project Job Orders for small maintenance projects that are generally $150,000 or less and to create project Job Orders for project support costs associated with larger Capital Projects. It is also used to request work and to monitor and “control’ project budgets. On small maintenance project Job Orders, one Work Order is issued to the CCF work group to serve as a budget place holder only – this is usually the only Work Order that contains an “estimate.” Then, Work Orders are issued for various enterprises/services to charge time, materials, testing fees, contract fees, etc. On the larger capital project Job Orders, both the “Is Project” flag and the “Allow SR” flag are checked. One Work Order is issued to the CCF work group to serve as a budget place holder only. Then CCF issues planned, “scope specific” Work Orders for the various enterprise/service groups on an as needed basis as directed by the Project Manager to provide various support to the project. By allowing Service Requests; however, the project manager also has the ability to contact Customer Service to have Service Requests issued when the work requested will require multiple trades and/or when deployment is more urgent than a planned “Work Order” would allow. CCF is not an enterprise group; therefore, it is not used for the billing of CCF staff’s time to projects.