Using BIM on a real Project - Welcome

advertisement

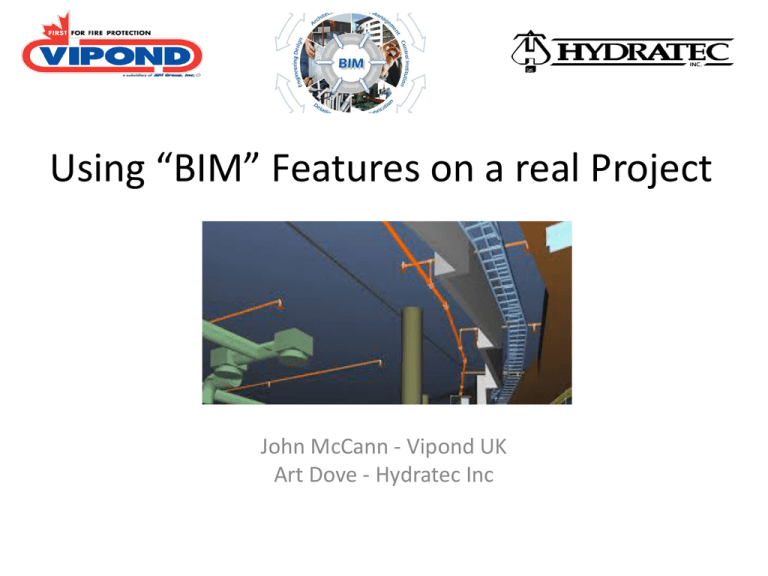

Using “BIM” Features on a real Project John McCann - Vipond UK Art Dove - Hydratec Inc INTRODUCTION: • The Project: • The Scope of Work: • The Process: • Challenges/ Benefits: • Questions The Project: New Asda Store - 40,000 Sq. Ft Scope of Works: • Design and Install New Fire Sprinkler System. • 40,000 Sq. Ft New Store. • The store sits above the Car Parking which is below. • The Store has a Storage Tank and Electric and Diesel Fire Pumps. • Asda required the design to be carried out using “Revit” / Autodesk) software. • There are 4 Levels of “Bim” This project was Level 2. “COBie” was not requested. The Process: 1 • The design process involved the different disciplines • Architectural. • Structural. • Mechanical, Electrical, Plumbing (MEP) • Refrigeration. • Fire Protection. • Uploading their “Revit” models onto “Autodesk Buzzsaw”. • From Buzzsaw we downloaded their models onto our company server. • The Revit models are large files for example the Architectural = 113mb • So you need plenty of hard disc space for this process. • We use an add on software called “Hydracad” that while it uses the Autodesk platform, allows us to design the Fire Sprinkler system more efficiently. The Process: 2 • The conversion of the “ Revit “ files while using “ Hydracad” go to AutoCAD 2D Drawing format. • During the design process, in “Hydracad”, we assign certain attributes to the pipework/fitting/sprinklers etc., • Once this is completed we can then convert the drawing into AutoCAD 3D model and then generate a “ Revit” 3D MEP File. • A New File has to be set up in Revit to link in all the disciplines, including plan views, and sections. • Once the new file is set up, and the Hydracad/Revit 3D content is installed in the file, then adjustments can be made to suit coordination and clash issues. The Coordination/Clash process: • Conducted by the CDM coordinator who used “Navisworks” for clash detection. • Clash detection and Coordination issues are then sent back to us in the form of a Clash Report. We use the interference check in “ Revit” to verify the clash. Clashes Page 1 of 1 Clash Report Sprinklers & CBES Model Image Tolerance Clashes New Active Reviewed Approved Resolved Type Status 1.00mm 2 2 0 0 0 0 Hard OK Item 2 Item Item Item ID Type Name GUID: GUID: CBES 9c050a8aColdroom x:-12546.63, 03180ad2Pipe 2014/3/26 Light Shell 5445-4c7dy:16805.04, 7b8a-4005Types 10:10.48 8fb79a891500 z:602.10 [511776] 351c722ce393 391a36aaecc9 [905964] GUID: GUID: CBES 7348930bColdroom x:-12446.63, 03180ad2Pipe 2014/3/26 Light y:14995.73, 7b8a-4005Types Shell 7494-4a8810:10.48 8fb784751500 z:593.10 [511808] 351c722ce3f3 cb614ceb5122 [906167] Clash Date Status Distance Description Name Found Clash1 New -18.47 Hard Clash2 New -11.60 Hard Clash Point Item ID Item 1 Item Name Item Type Shell Shell Challenges/Benefits: Challenges: • Training in the use of this software and understanding of the process is critical. • A clear and concise plan must be communicated to all stakeholders who are involved in the process, and everybody must be on board. • One break in the link can cause all sorts of delays and errors. • Using BIM adds 30-40% additional cost to the design process. The Benefits: • Better collaboration at the MEP Level. • Reduction in RFI ( Request for information) • Better Sub Contractor efficiency • Less rework and expensive changes • More accurate and timely as installed information. QUESTIONS