HERE

advertisement

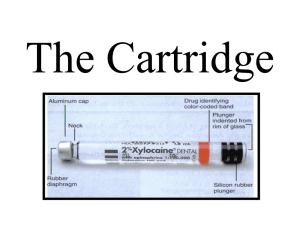

Cartridge Reloading Handgun Ammunition R.Leard January 2015 Disclaimer DISCLAIMER: Reloading and use of reloaded ammunition can be hazardous. Follow best practices and loading manual recommendations with respect to limits. It is not recommended that you experiment with loading ammunition, follow published best practices and guidelines. This course is general introduction, all loads will not function the same in every handgun. Always wear safety equipment such as eye shield and gloves. We do not assume liability for other persons who may use methods or data from this course. Topics Introductions – All Required material for the course Goals & Objectives Cartridge Components Safety Tools Loading - Efficiency through batch processing Why ammunition fails Local Materials/Suppliers/Costs Shoot Required material Handouts, targets, patches, primers, powder & projectiles included Bring Ear Defenders & Eye protection Bring Snacks Time commitment 4-6hrs Goals & Objectives To understand the materials, tools and techniques to reload handgun ammunition that functions consistently To reload handgun ammunition safely To understand best practices for consistent reloading To demonstrate the impact powders, powder volumes and projectiles have on functionality and accuracy An interactive course, please use the tools to reload and share experiences If we don’t know the answer to a question, we’ll get you one What Cartridges Fail (Fail to Load/Discharge) Most Of the Time – Cartridge Overall Length (COL) – Too Long – especially problematic for semi-auto’s, failure to feed. - Squib Loads – very dangerous – projectile lodged in barrel Sometimes – Primer not seated, risk of out of battery discharge for semi’s and failure chamber or rotate for wheel guns. – Primer too hard, failure to ignite – not all primers are equal. – Not enough crimp – failure to chamber – Too much crimp – shaved lead – failure to chamber Rarely – Cartridge Overall Length (COL) – Too Short – especially problematic for semi-auto’s, failure to feed – jams on feed ramp. – Bad Primer - Failure to fire Cartridge Components Primer Case Powder Projectile Cartridge Components - Primers Berdan Soft Vs Hard Revolver Vs Semi-Pistol Crimped primers – Military use CCI, Federal & Winchester Federal are softer, use for revolvers Around 54$ 1000 Cartridge Components - Case Material: Brass Nickel plated brass Aluminum – I do not reload – heard you can Steel – I do not reload – heard you can Common Problems – Cracked, dented Sizing - I have never trimmed a handgun case – not bottle necked – little stretch lengthwise Reusability – reload until case failure, never seen it happen, occasional cracked case. Some people only reload 4 times, then discard Not all brass is the same, I only keep Federal and Winchester 9mm 45 ACP brass harder to find, so not as picky Prefer nickel, just a nicer looking round Marking – Mark your cases with a color so they are easily recovered Cartridge Components - Powders Metering – affected by shape of flakes – issue for light loads Shotgun powders often used for pistols Burn rates – shorter barrels need to generate speed quicker then longer rifle barrels Larger Projectiles, less powder, increased pressure Cost – cheaper to buy 8lbs vs 1lb containers, but be sure you will use it Common Bullseye, Red Dot, Win 231 Less Common Vihtavuori, Clays Cartridge Components - Projectiles Typically Lead or Jacketed Projectile Weights - Follow guidelines Casting your own – need to shoot a lot to make it worth while Common Shape Round Nose Truncated Round Nose Semi-Wad cutter Wad-cutter Solid base or Hollow Base Cartridge Components - Projectiles Lead – Can “lead” your barrel Not all 9 mm barrels are the same size – some like .355, some .357 Not all 9 mm barrels are the same shape Some barrels are not recommended for use with lead - Tanfoglio Weights - Follow guidelines Casting your own Common Shape Round Nose Truncated Round Nose Semi-Wad cutter Wad-cutter Solid base or Hollow Base Case Preparation Cleaning: Tumbling with corn cob or walnut media 2- 4 hrs Inexpensive, perfectly acceptable results Tumbling with stainless steel media - not sure how long it takes Expensive Do not remove primers before tumbling in corn cob/Walnut media – Media will plug primer hole Cleaning Primer Pocket – it’s your time Reloading Tools In the order used Baskets Paper Towels Powder Measure Scales – Balance beams & Electronic Priming Tool – Handheld vs on press Dies – 2, 3 & 4 die sets Press – Single stage, Progressive Manually Indexed& Progressive Auto-Indexed Shell holders Case Lube – spray vs pad Pliers Calipers - electronic Marker Cartridges – Putting it all together Determine objective for ammunition Fun – company ammo – don’t worry as much about projectile tolerances Target shooting IPSC – Power Factor concerns as well as material concerns Not all places allows all types of ammo – Lead Vs Jacketed Vs Steel Core Determine Powder load Check books, trusted websites & Make notes For handgun ammo, once I determined my start load, I vary it my .2grs from my min to my max as determined from reference manuals Determine COAL, based on your handgun and reference material Crimp or not to crimp Cartridges – Putting it all together Cleaned Deprimed Resized - At this point I load test rounds (old primer, no powder usually 3 to test in gun) Reprime Expand Case Mouth Throw Powder Seat Projectile to match desired COAL Crimp Common Mistakes & Recovery Primer Sideways Primer Upside Down Primer in a cracked case Not sure about power load Cartridge disassembly – Demo tools Safe Disposal – WD40 Shaved Lead Crushed Cases Cartridge – Not seating properly in chamber Hardest case to disassemble = Wad-cutters Make Some Ammo Load and shoot ammo: 9mm Jacketed & Lead 38 Special Semiwad cutter & Wad Cutter - Lead Mouse Farts Heavy Loads 45 ACP Semi-wad cutters Local Suppliers Brian Densmore: – Email: m9x57@hotmail.com – Ph: 902.568.2990 – Middle Musquodoboit Jd's Shooting & Fishing Supplies – Email: jdssupplies@eastlink.ca – Ph: 902.852.2551 – Prospect Bay Better Buy Sports – Limited Online