IS365SAPInventoryWarehouseProcess

advertisement

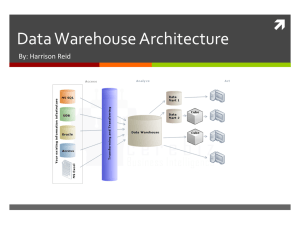

Inventory and Warehouse Processes Introduction Inventory and warehouse management are closely related to the fulfillment and production processes Warehouses often supply raw materials to manufacturing Warehouses store and move finished and semifinished goods Warehouse management is an optional subsystem that must be enabled and configured Processes Process change Picking and return http://www.youtube.com/watch?v=Q20nhhT07f 0 http://vimeo.com/12948899 Automated pharma http://vimeo.com/72337318 Inventory without WMS Inventory With WMS Types of Goods Movement Receipt from production or procurement Goods issue to production or fulfillment Decreases raw material inventory Transfer postings change the status of a good Stock transfers Increases finished goods inventory Move goods from plant to plant or storage location I’ll go through these in sequence Goods Movement Goods can be received in the warehouse as a result of Procurement Production You received purchased goods in the procurement lab Goods leave the warehouse Through shipping Through disposal SteelCase Case 10 plants Small short-term warehouses to store goods for a matter of hours 6 regional distribution centers Goods Status Goods in the warehouse can be Unrestricted Held for a customer or other reason In quality inspection In transit These goods are stored in storage locations Goods Status (Example) MB52 Warehouse stock Search for goods in a plant Restrict by materials types Goods Status (Example) Goods Status (Discussion) We can sell unrestricted stock Transit/Transf stock is stock in motion Restricted use stock includes reservations Blocked stock is stock received “conditionally” pending acceptance A batch is a subset of stock managed separately from the material itself Goods Movement (SAP) Goods Receipt Remember it’s a receipt of goods into inventory from a vendor Goods receipts are triggered by Goods received from vendor from purchase Unplanned receipts Customer returns Logistics / Materials Management / Inventory Management / Goods Movement Goods Receipt (SAP) Again, these are configurable Goods receipt (Other) MB1C Types of Goods Receipts Goods Issue To review, goods are leaving inventory typically sold to a customer Goods issue event is triggered by Planned resulting from a sales order Unplanned Scrap / internal consumption / sampling Goods Issue (Types) Internal Warehouse Processes What happens in the warehouse stays in the warehouse We are just moving goods around. We are not revaluing them, buying them, or selling them We will discuss in 2 parts The organizational units The processes of moving goods WM Organizational Units A warehouse number defines a warehouse complex made up of one or many buildings Within a warehouse we have storage types We can configure as a physical or logical subdivision of the warehouse complex WM Organizational Units WM Organizational Units There will likely be several storage bins having the same storage type Storage bins belong to a section and picking area (other organizational units), and have a capacity (weight, units, or both) WM Config We have transaction codes to create warehouses, storage types and other needed OUs WM Organizational Units WM Bin Reports We can look at bin utilization and time in bin WM Bin Creation We create storage bins based on templates or perhaps manually WM Organization Doors are locations where goods are received or shipped WM Organization (Door) Doors are configured through the IMG WM Processes We add additional steps to move goods from GR loading area to the warehouse (bins) We add additional steps to move goods from warehouse to GI loading area And a bunch of steps within the warehouse itself to do the picking and packing Transfer Postings Change the status of a material in stock Unrestricted use QA / QC Blocked In transit Transfer postings do not always result in the physical movement of goods They might just change the logical status of a good Transfer Postings (Examples) From vendor owned inventory to company owned inventory The vendor stores their materials in our warehouse (consignment stock) Change a material’s characteristics over time Transfer Postings (Movement Types) Selected transfer postings Process Example (GR) We receive goods into an interim storage area We move goods into the warehouse through a stock transfer Process Example (GR) I issued a GR for a purchase order where WM is enabled The goods are received into a holding area with a storage bin corresponding to the PO Process Example (GR) The detail shows ‘interim storage Process Example (GR) We create a transfer order to put away the material Process Example (GR) And finally the transfer order gets processes (here we put away) Process Example (GR) And now my goods show up in the bins Stock Transfers Use to physically move materials from one organizational level to another Plant Storage location Etc. Types of Stock Transfers Storage location to storage location Plant-to-pant transfer Company-code-to-company-code transfer Stock transfers do not take into account Transportation costs Negotiated value or changes in pricing Stock Transport Orders satisfy this need Stock Transfer (SAP) Stock Transfer (Illustration) Stock Transfer (Details) The procedure can be performed two ways 1-step process 2-step process Goods issue and goods receipt happen at the same time Goods go through an in-transit status between goods issue and goods receipt A FI document is generated to record the change in inventory Stock Transport Orders These orders account for delivery and stock in transit Billing can also be performed Valuation can be changed Progress of the transport can be tracked The sending plant is the seller and the receiving plant is the buyer Warehouse Organizational Data First, the warehouse management sub system must be enabled for the following to work Enabling the warehouse management process involves additional steps in the goods issue and goods receipt phase Fulfillment Steps After outbound delivery and before goods issue Warehouse issues transfer orders Create and confirm Goods physically move from storage bins (locations) to interim storage Production (steps) The same confirmations are made When raw materials are issued to production When finished goods are transferred back to the warehouse WH Controlling WH Controlling http://www.tcodesearch.com/transactioncodes/search?module=LE&comp=LEWM&desc=Warehouse%20Management