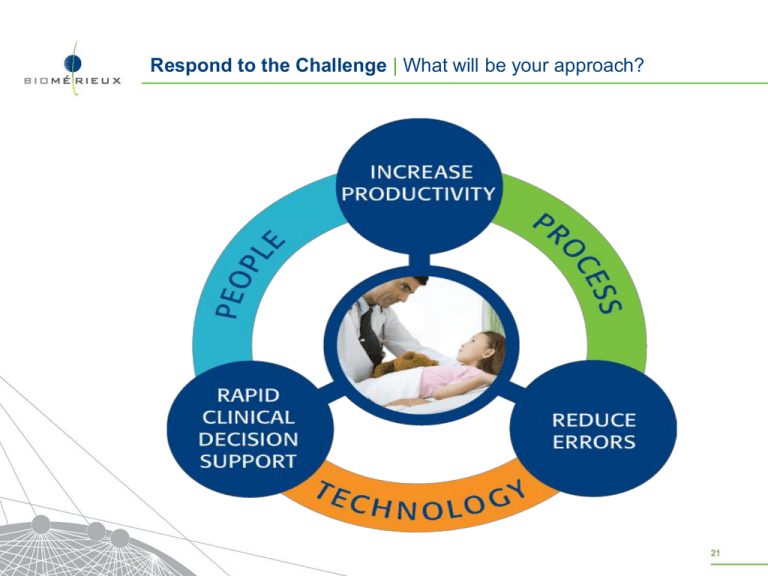

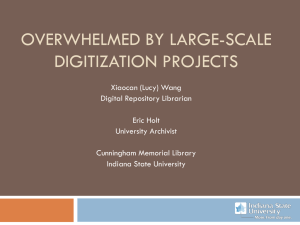

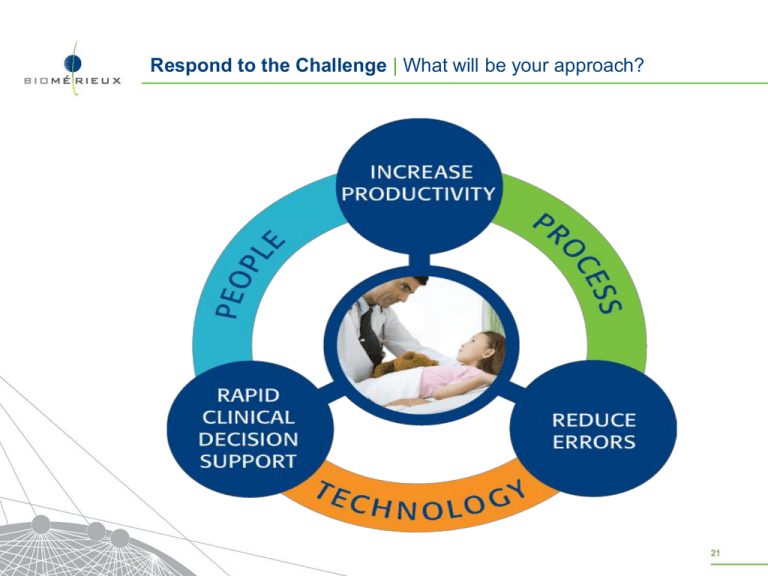

RespondOptimization

to the Challenge

| What willapproach

be your approach?

Workflow

| Our assessment

1

People: The rate limiting factor of Change

Resistance to change is a significant barrier to realizing results and savings

When pursuing transformations, organizations rarely realize the benefits or retain the value they

anticipated. While there are many reasons for this, the following survey of CEO’s shows that 5 out

of the top 10 business transformation showstoppers are ‘people and organizational’ issues.

Top

Resistance

Case

Sponsorship

Unrealistic

Expectations

72%

65%

54%

Project Management

for Change not Compelling

Project

Scope

No

82%

to Change

Inadequate

Poor

10 Barriers to Success

46%

Team Lacked Skills

44%

Expansion / Uncertainty

44%

Change Management Program

Not

IT

43%

Horizontal Process View

41%

Perspective not Integrated

36%

PERCENT

“Source:

“Soft skills”?

Hard Impact.

OF FIRMS

Deloitte & Touché Survey of CEO's regarding Business Transformation: Top 10 Barriers to Success, 2004.”.

2

Process of Change Management

Commitment to change

Change is managed effectively

COMMITMENT

ADOPTION

GO-LIVE

• Project Rework

• Sub-Optimized Delivery

• Lack of Project Team and

Leadership Alignment

• Delay/No Adoption

• Missing Accountability

• Minimized/Missed Benefit

Realization

• Lost Investment Opportunity

UNDERSTANDING

UNAWARE

AWARENESS

CONFUSION

NEGATIVE PERCEPTION

Time

GO-LIVE

SUPPORT WITHDRAWN

ROI PROJECT TERMINATED

Change is not managed

3

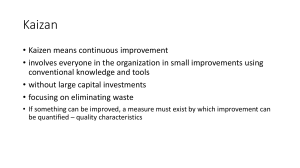

Creating the “LEAN” Microbiology Lab

1. Strategic Assessment

2. Transformation

Unbiased LEANSigma observation

and data analysis of your lab

Collaborative group effort

Kaizen events

Rapid Improvement Workshops

Staff schedules

Staff priorities

Volume patterns

Turnaround time analysis

Specimen physical flow

Value streams

Unnecessary or

over-processing

opportunities

4

Strategic Assessment

Strategic Assessment

Pre-work

• Introductory

visit with site

leadership

• Pre-audit data

request

• Type/volume of

samples

• Segmented

staffing data

• Working hours

• Organization

chart

• Performance

metrics

• Building layout

• Discuss

challenges

Kick-off

• Introductions &

kick-off

• Review schedule

• Walk the process

• Data gathering

• Pareto analysis

• Physical Layout

• "Cycle time

analysis' or

snapshot

observation

• Volume arrival

patterns

• Spaghetti

diagrams

Data

Collection

Future

state

• Current state

value stream

map

• Lead time

analysis

• Interviews

• Data analysis

potential linkages

between

observation and

performance

• Current state

data validation

with site

leadership

• Define

"improvement

roadmap”

• Process

• Layout

• Staffing

• Equipment

• Future state

definition

Report-out

• Prepare final report

• Recommendations

for improvement

• Quantify benefits

• Review

opportunities and

next steps with

stakeholders

5

What is Important to the patient?

Wasted Time & Activity

Core Process Value

Backlog of

requests

Excessive Motion

(Walking to Next Task, etc.)

Defective Process

(Identifying, Handling, Fixing)

OPERATIONAL LEAD TIME

Missing

Information

Waiting

for next Process

Review/QA

Call or Log

information

Key: Improved Processes to Increase “Core Value”

© 2009 Guidon Performance Solutions, LLC. All rights reserved. Guidon Performance Solutions is a licensee of LEAN

Sigma®,

a service mark of TBM Consulting Group.

You must optimize the whole, not just the parts…

7

Transformation

Kaizen Event: Transformation

Pre-work

• Review

opportunities and

next steps with

stakeholders

• Pre-visit

planning

Kick-off

• Collaborative

group engagement

• Lean training

Current

state

• Map the current

state from

specimen receipt

to result

• Review the

process for

improved

turnaround times,

eliminate waste,

reduce errors,

minimize

touches.

Future

state

Follow up

• Standardize the

process

• Develop and map

the new process

• Assign ownership

of key tasks

• Training in change

management

• Recommendations

for improvement

8

• Prepare final report

• Follow up to

measure

improvements

5 S Projects

:| |Organization

Methodology

Workflow

Optimization

Our assessment approach

Before

After

9

Lab Planning | Designing the Future Laboratory

Defining the future laboratory and meeting the needs for growth

Current

and future state analysis

Technology and infrastructure options that facilitate change

Design approaches that facilitates lean and workflow optimization

Lab space planning and design

Approaches to lab automation

Technology assessments

Workflow planning

Lab Relocations

10

Lab Transformation

:| Keys

to Success

Workflow

Optimization | Our assessment

approach

11

Examples of performance improvement – Maximize Quality

Performance Improvement:

• Over 1100 urine were contaminated/month

• 50% were causing re-work and over-processing

• Design new process and monitor improvement

>80%

Reduction in Contamination

We saw improvements quickly (over two months).

Over 6 months, contamination from 18% to < 4%

Reduce cost by $30k per month

12

Examples of performance improvement – Rapid Decision Support

• Identify drivers for this distribution

• Design new process and monitor improvement

6 months later

Median: 87 hour 63 hour

Top 25%: 119 hour 89.1 hours

13

Performance Improvement

24

hours

Example of performance improvement – Patient Centric

“Two years later, the results on workflow, turnaround times (TATS),

and patient outcomes have been dramatic.”

Joseph Campos, Ph.D.

Director of the Microbiology and Molecular Diagnostics Laboratories

Children’s National Medical Center

14

In summary

Clinical microbiology will remain a “growth based” science

Automation will remove “touches” from the manual

process, but will not be effective unless you transform your

workflow to maximize the technology investment

We must focus on efficient delivery of clinically relevant

results in order to accelerate therapeutic decisions and

improved patient outcomes

Performance Assessment and Transformation is a Quality

Initiative

Focus is on processes and systems that serve the Patient

Improve level of service and customer satisfaction

Improve employee satisfaction

Free up resources and be prepared for increasing test volumes

15

16