Manufacturing Skill Standards Council Overview

advertisement

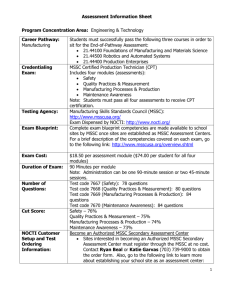

Manufacturing Skill Standards Council (MSSC): Certified Production Technician Presenter: Leo Reddy, CEO 1 About the Manufacturing Skill Standards Council (MSSC) An industry-led standards-based, training, assessment and certification system focused on the core technical skills and knowledge needed by the nation’s front-line production and supply chain logistics workers. The nationwide MSSC system, based upon industrydefined and federally-endorsed national standards, offers both new and incumbent manufacturing workers (entry-level through first-line supervision) the opportunity to credential the skills increasingly needed in the technology-intensive jobs of 21st century advanced manufacturing: the “Industrial Athlete of the Future.” 2 MSSC: What is the Certified Production Technician (CPT) Modules: Safety; Quality Practices & Measurement; Manufacturing Processes & Production; and Maintenance Awareness Green Production (Available Oct. 2011) 3 How it Works MSSC: Certified Production Technician (CPT) Skill standards MSSC National Standards developed 1999-2001 involving 700 companies, 4000 workers, 350 experts at cost of $5 million federal/$4 million industry in-kind. Endorsed by federal National Skill Standards Board in 2001 and used as research basis for USDOL Advanced Mfg. Competencies Model and US Dept. of ED Manufacturing Career Pathway MSSC National Experts Panel reviews and updates standards annually. Curriculum The three types of courses offered by MSSC as follows: Integrated Course: 140 hours, continuous, intensive study covering all four modules, with all 4 assessments preferably given at the end of the course. Recommended primarily for dislocated workers, summer semester students or others who have time for continuous study, such as continuous study throughout one semester or academic year. Modular Courses: 35-40 hours, 3-credit equivalent, one course for each of the four MSSC modules with an assessment given at the end of each course. Recommended primarily for students and others studying in the framework of academic semesters or school years. “Fast Track” Courses: 15-18 hours for each of the four MSSC modules with an assessment given at the end of each course. Recommended primarily for experienced incumbent workers with limited available time for study. Not available to HS students. 4 How it Works MSSC: Certified Production Technician (CPT) Testing Centers/Process Tests must be given at MSSC-authorized Test Center. Fee for test center authorization training: $500 per center, $250 per center for statewide initiatives adding 5+ centers. MSSC issues certificates for success in each Modular CPT test, but full CPT Certification only for success in all four Modules. Cost: Postsecondary Education: One-time registration fee: $60 Test Fee: MSSC Cost - $40 for each of four CPT Modules. Recommended markup for test center cost: $15 for center. Secondary Education: One-time registration fee: $25 Test Fee: MSSC Cost: $19 for each of four CPT Modules 5 Benefits: MSSC - Certified Production Technician (CPT) MSSC benefits both employers and the manufacturing industry as a whole by: Decreasing recruitment costs by providing job candidates with industryrecognized credentials Eliminating time and costs associated with providing remedial education and training Meeting employer and industry needs for workers with the right core skills and knowledge to keep pace with technological change (including math, science, reading, writing, communications, IT, analysis, problem-solving, teamwork, organization, planning, and basic technical skills) all in a manufacturing context. Increasing productivity and innovation through reinforcement of core knowledge and skill sets Enabling employers to use a diagnostic tool to benchmark their workers against high-performance national standards to identify skill gaps and increase their ROI for training by targeting skill enhancements that close the identified gaps Enhancing the ability to attract, motivate, and retain qualified employees 6 NAM-Endorsed Skills Certification System MSSC Program Elements Certified Production Technician (CPT) MSSC Certification System Tools National Standards Curriculum Instructor Training Proctor Training Assessments Credentials Industry Standards Developed and nationally validated with 4000 workers, 700 companies, 350 experts (1999-01) $5 million federal investment / $4 million private in-kind investment Endorsed by National Skill Standards Board in 2001 Expanded in 2009 to include Logistics (CLT) and again in 2011 to include Green Production (CPT) Reviewed and updated annually by MSSC National Experts Panels on manufacturing production and logistics Based on actual work activities performed and skills and knowledge needed to perform the work CPT Key Activities Safety Quality Practices & Measurement Work in a safe an productive manufacturing workplace Perform safety and environmental inspections Perform emergency drills and participate in emergency teams Identify unsafe conditions and take corrective action Provide safety orientation for all employees Train personnel to use equipment safely Suggest process and procedures that support safety of work environment Fulfill safety and health requirements for maintenance, installation and repair Monitor safe equipment and operator performance Utilize effective, safety-enhancing workplace practices Participate in periodic internal quality audit activities Check calibration of gages and other data collection equipment Suggest continuous improvements Inspect materials and product/process at all stages to ensure they meet specifications Document the results of quality problems Communicate quality problems Take corrective actions to restore or maintain quality Record process outcomes and trends Identify fundamentals of blueprint reading Use common measurement systems and precision measurement tools CPT Key Activities cont’d Process & Production Maintenance Awareness Green Production Identify customer needs Determine resources available for the production process Set up equipment for the production process Set team production goals Make job assignments Coordinate work flow with team members and other work groups Communicate production and material requirements and product specifications Preform and monitor the process to make the product Document product and process compliance with customer requirements Prepare final product for shipping or distribution Prepare preventative maintenance and routine repair Monitor indicators to ensure correct operations Perform all housekeeping to maintain production schedule Recognize potential maintenance issues with basic production systems, including knowledge of when to inform maintenance personnel about problems with: • electrical systems; • pneumatic systems • hydraulic systems; • machine automation systems • lubrication systems • bearings and couplings Train workers in environmental issues Implement and promote environmental programs, projects, policies or procedures Conduct environmental incident and hazard investigations Conduct preventive environmental inspections Monitor environmental aspects at each stage of productions Implement continuous improvement in environmental assurance Use advanced materials in production to reduce waste Reprocess materials by recycling and reuse Curriculum Blended learning with online and instructor-led classroom content Fully-online with online instructor E-learning provides interactive learning experience http://www.msscusa.org/publications/mssc_elearning_overview_short.wmv Includes pre- and post-tests to allow students and instructors to gauge progress Textbooks provide compliment to e-learning Curriculum Options 2 course formats Regular Courses: 35-40 hours, 3-credit equivalent, for each module Fast Track: fully-online, 16-18 hours for each module (CPT only, does not include Green); designed for incumbent or dislocated workers with previous manufacturing experience Instructor Training Authorized Instructors or use of Instructors Package required All Fast-track or fully-online courses require online instructor Instructors able to track individual progress through learning management system Instructor Training available at national training centers, or if you have 6 or more instructors, we will send our master trainer to you • CPT Instructor Training – Jeffersonville, IN Certification Individuals who earn a full-CPTAE credential will receive: • A diploma-style credential • Wallet card • Sew-on patch for their uniform Note: “AE” designates ANSI/ISO Edition Certification Qualifying for CPT: Individuals earn a certificate for each module passed Must earn all four certificates (Safety, Quality, Process and Production, and Maintenance Awareness) to earn full-CPT At this time, Green certificate is not required to obtain full-CPT certification How It Works MSSC: CPT Cost (non-profit) Per Site (Set-up Costs) Post-secondary Secondary $500.00 No charge $2200.00 $2200.00 $1500.00 $1500.00 Registration Fee (one-time fee) $60.00 $25.00 Each Regular Course (35-40 hr) $130.00 $65.00 Each Fast-track Course (16-18 hr) $65.00 n/a Each Assessment $40.00 $19.00 $740.00 $361.00 Assessment Center Authorization / Proctor Training 3-day Instructor Training Class Instructor Package only Per Candidate(Ongoing Costs) Avg total per candidate (one registration, one regular course, one assessment) Benefits to Industry Offers a pipeline of highly-skilled knowledge workers Decreases recruitment costs by providing job candidates with industry-recognized credentials Eliminates remedial training costs Serves to attract, motivate and retain qualified employees Provides agile workers capable of keeping pace with technological change Added Benefits to Industry: ISO 17024 MSSC only U.S. certification body accredited under ANSI-ISO 17024 for manufacturing and logistics Can be deployed globally by multinationals to ensure common practice in all plants Reduces costs through economies of scale Standard for use with foreign governments in requiring certified job applicants Can be used with all suppliers to ensure quality of their workforces and seamlessness of workforce training practices Benefits to Workers Document skills and knowledge in short period at low cost Obtain industry-recognized, nationally portable credential Improve career advancement opportunities and earnings Enhances transferable skills applicable to all sectors of manufacturing or logistics Benefits to Educators Increases industry client base through MSSC network and nationally recognized certificationbased training Increases student enrollment through on-demand elearning solutions Provides instructor training to increase skills and opportunities Multiple delivery formats allow flexible scheduling Enables schools to offer certifications as well as degrees Contact Information Neil Reddy Executive Director reddyn@msscusa.org 703.739.9000 x221