1. Classification of the transported goods

advertisement

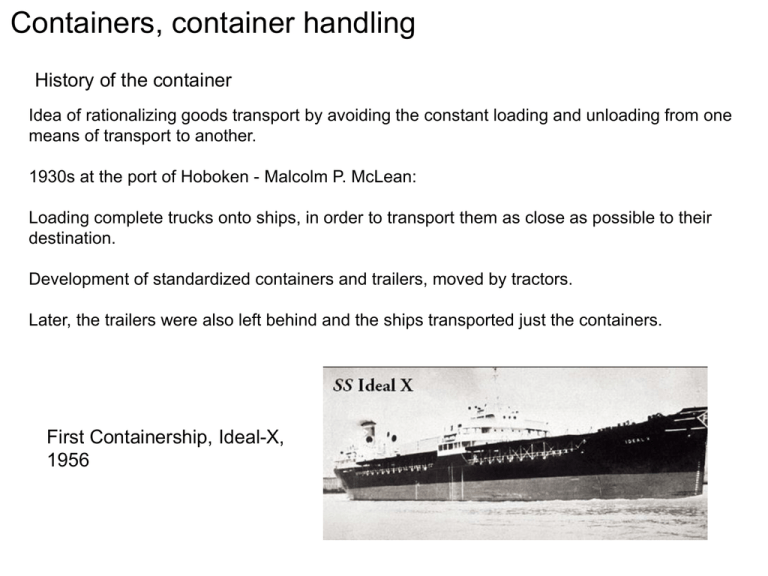

Containers, container handling History of the container Idea of rationalizing goods transport by avoiding the constant loading and unloading from one means of transport to another. 1930s at the port of Hoboken - Malcolm P. McLean: Loading complete trucks onto ships, in order to transport them as close as possible to their destination. Development of standardized containers and trailers, moved by tractors. Later, the trailers were also left behind and the ships transported just the containers. First Containership, Ideal-X, 1956 Container design and types ISO containers Basic dimensions and masses of freight containers ISO 1 Container design and types ISO containers Basic dimensions and masses of freight containers ISO 2 Advantage: worldwide utilized Disadvantage: inner dimensions don’t fit EURO-pallets Container design and types Unit 45’ Container design and types Swap bodies Advantages: Disadvantages: dimensions compatible with EURO-pallets, lower tara weight, multiple handling possibilities cannot be (or max. 4 layers) stacked lower strength Container design and types Comparison of swap bodies and semi-trailers Swap bodies: - Multimodal - Low tara weight Semi trailers: - Monomodal - Greater inner height Container design and types General purpose containers, dry cargo containers or box containers. Features: Closed steel construction End / side doors No ventilation Corner fittings Forklift pockets Container design and types Open-sided containers Open-top containers Container design and types Open-sided, open-top containers Platforms, flatracks (collapsible end or fixed) Container design and types Bulk containers Container liners Standard containers -> bulk containers Loading: Pneumatic Belt conveyors Unloading: Tilting Filling domes Container design and types Bulk containers Unloading by tilting max 30” Unloading through side openings Container design and types Tank containers Light weight structure Swap-tank Container design and types Flexitanks Non-hazardous liquids in standard container Container design and types Refrigerated containers There are two basic types of refrigerated container (reefer) which have each developed differently over the course of time: Porthole refrigerated containers, also called insulated or Conair containers, do not have their own refrigeration unit. They are thus reliant on an external supply of cold air. Refrigeration units of various types, permanently installed on the ship, permanently installed in the terminal or clip-on units for individual containers, are used for this. Container design and types Refrigerated containers There are two basic types of refrigerated container (reefer) which have each developed differently over the course of time: Porthole refrigerated containers, also called insulated or Conair containers, do not have their own refrigeration unit. They are thus reliant on an external supply of cold air. Refrigeration units of various types, permanently installed on the ship, permanently installed in the terminal or clip-on units for individual containers, are used for this. (see below) Integral refrigerated containers, on the other hand, have an integrated refrigeration unit, which is generally powered nowadays using a 3-phase electric power supply Container design and types – container handling Roll-off containers (ARC) Max. length: ca. 6 m Max. height: ca. 2,3 m Application: - Bulk material - Special containerized equipment - Door-to-door transport Handling with specialized lifting truck Chain-system Rope-system Hook-system Rail – road possible (ACTS) Container handling Lifting at the top corner fitting Spreader Twistlock Ship to shore container gantry cranes Container handling Lifting at the top corner fitting Automatic stacking crane systems Rubber tyred gantry crane Container handling Lifting at the top corner fitting Reachstacker Lifting at the forklift pockets Straddle carriers Container handling lift trucks Container handling Side loaders Container handling Grapple arm lift The spreader can adjust its length to lift containers from 20’ to 40’ using ISO floating twistlocks. It also features grapple arms to lift trailers, swap bodies (C715, C745) and bottom lifting containers. Powered Pile Slope (PPS), tilt (optional), rotation and side shift features enable easy location onto containers or near pick-up points achieved with smooth control technology. Folding legs Special truck required Limited load on the legs Requires great accuracy Container handling Rail to road systems (special truck+carriage) Mobiler ACTS Container handling Rail to road systems (special railway carriage) Cargobeamer