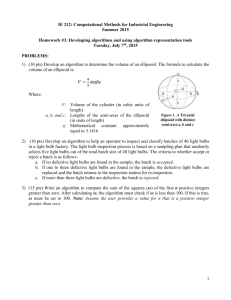

Sampling Plan Table for =

advertisement

R. Saltzman Acceptance Sampling Problems Operations Single Sampling Plan Table for Attributes when = .05 and = .10 (1) (2) (3) c LTPD/AQL AQL*n 0 45.10 0.051 Steps to using the Table: 1 10.96 0.355 2 6.50 0.818 1. Calculate LTPD/AQL ratio 3 4.89 1.366 4 4.06 1.970 2. Find nearest entry in col. (2) to ratio 5 3.55 2.613 -- this entry's row gives c 6 3.21 3.285 7 2.96 3.981 3. Staying in this row, set the col. (3) 8 2.77 4.695 value = AQL*n, and solve for n. 9 2.62 5.425 10 2.50 6.169 : : : 1. Larry, a secretary, makes 500 photocopies of Professor Curly’s exam. Since the photocopying machine sometimes prints a blank page, Larry must inspect the quality of the batch of exams. An exam with a blank page is considered to be defective. An acceptable quality level is 1% defective, but Professor Curly will tolerate no more than 6% defective. Assuming = 5% and = 10%, what single sampling plan should Larry use, i.e., 1a) How many exams should Larry randomly sample from the batch of 500? 1b) What is the largest number of exams that can be defective in the sample without causing Larry to reject the batch? 1c) What decision is made when a random sample contains 3 defectives? 2. A satellite telecommunications firm produces a special piece of spy equipment that uses the latest microprocessor chips, which it receives in large batches from the supplier. Because of the sensitive nature of the application, the firm wants a 5% probability of rejecting batches with 0.1% defective and a 10% probability of accepting batches with 0.3% defective. 2a) What is the sampling plan they must use to achieve this? 2b) Suppose one particular sample contains 4 defectives. What should be done with the batch? 3. PennSylvania, Inc. produces light bulbs and claims they will last for 1,300 hours on average. Assume that their manufacturing process produces light bulbs that have a lifetime that is normally distributed with a standard deviation of 200 hours. 3a) Design a sampling plan that has a 5% chance of accepting a batch whose average lifetime is only 1,200 hours and a 2.5% chance of rejecting a batch with an average lifetime of 1,300 hours. 3b) Suppose a particular sample gives a sample mean of 1251.3 hours. What decision is made about the batch of light bulbs from which the sample was drawn? 4. A candy store receives large boxes of candy canes from a manufacturer who claims that the average length of their candy canes is 20 cm. Assume that the manufacturer actually produces candy canes whose length is normally distributed with a standard deviation of 1.28 cm. 4a) Design a sampling plan that has a 2% chance of rejecting a box of candy canes whose average length really is 20 cm, and a 4% chance of accepting a batch whose average length is just 18 cm. 4b) Suppose a random sample of candy canes from a box yields a mean length of 18.7 cm. What decision should be made about the box of candy canes from which the sample was drawn? Answers. 1a) n=82 exams; 1b) c=2 defectives; 1c) Reject batch. 2a) n=3981 chips, c=7 defectives; 2b) Accept batch. 3a) n=52 light bulbs, c=1245.6 hrs. 3b) Accept batch. 4a) n=6 candy canes, c=18.93 cm; 4b) Reject box.