BbtB-LEGO-Track

advertisement

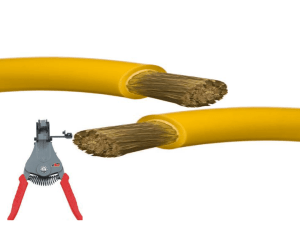

Hacking with LEGO Bricks NOT for the LEGO Purist! Graphic images involved! Turn back now! ( LEGO is a trademark of the LEGO companies) ( I am NOT affiliated with the LEGO companies ) Confessing my sins (and tips) I have used… • Cyanoacrylate (“Super-glue”) • Hot Glue • Xacto Micro-saw • Dremel moto-tool • SOLDER! • Use Non-LEGO elements!! Graphic Image Desktop Got non-LEGO scrap parts? • A use for non-LEGO bricks and plates! • Hold your precious LEGO while you cut, saw, glue and solder them! • You don’t want to waste your LEGO • You don’t care if you damage the non-LEGO bits! Start simple, and practice • Cutting my first green 2x2 tiles into a pair of 1x2 tiles for a roof project was tough, but I learned from it; • Practice on non-LEGO parts first! • Use non-LEGO parts as a saw guide • Hide the “cut side” under other parts • Use a micro-saw to minimize loss/gaps Making Adapter Tracks • Have you ever needed a 1/2 straight? • When you are nesting loops of track, that 5-inch straight track is a big shift, when you need 8 studs Two straights, two adapters • Sacrifice two regular straight tracks, and you get a 1/2-track and a 1-1/2 track – Cut the tracks at the 1/4 to 3/4 point – This puts the junction on a 2x8 “tie” – The split tie is how you align the parts • You can do this with curves and switch track as well, but you need to be careful Align your track parts! • There will be a gap from the saw to fill • Use non-LEGO to align the parts • Now solder the railhead parts • Short, quick soldering! • Copper foil? Add some Copper Foil Tape • Cut and lift the railhead • • • • Align the track Carefully add foil Anchor the railhead Hot-glue rail in place Stiffen your track joints • LEGO braces the joints of their track • You should also brace your joints! • AFTER soldering. • If you don’t, your joints may bend under pressure while assembling them… Smooth out the solder joint • Trains and cars bumping over a bad joint will derail a train and stop your fun • You can either sand it, or cut it flat! • Inside the gauge, and top of rail, get the work Was it worth it? • I have these parts on my shelf railroad • I think my club benefited from this effort on some of our public displays. For me, it was. Track Power Extensions • You cannot get sufficient power across a long distance using the normal LEGOsupplied power extension cables. – Wire gauge is too small for long haul… – Adding train motors adds more load… – Adding more cars, (or causing a motor to “stall”) adds more load. • LEGO designed this for safety! Why I made my decisions • PNLTC Guinness 2000 layout • Hard to get LEGO 1-meter power cords – They didn’t perform well daisy-chained • The Far End of our layout was 30’ off! – Trains slowed as they got to the far end – Trains sped up as they came back… • We wanted consistent train speed Debugging a big display… • Hot days/rooms will aggravate the thermal safety devices in Track Power Controllers and in Train Motors! • Thin wires loose more power over a given distance than larger wires. – This holds true for the railhead! You lose more power as you go farther from the power feed points! You need more power! To splice, or not to splice? • Splicing thicker wire is less work, but is also less efficient. – But, how much power do you need? • Soldering to the rail is easy enough • Soldering to the 2x2 power brick will require some grinding as well! – But it will be WORTH THE EFFORT! • Try 18-gauge wire. Maybe speaker wire? Opening the 2x2 Power Brick • Use two fine, flat screwdrivers – Two tabs near the cord – Two more on the other end • Approach from the bottom • Be very slow and gentle… • You should wind up with two pieces in the end… ---> Preparing the power brick • I use a small router bit in my Dremel tool,to widen the trough that supports the wire. – Be careful to preserve the tabs – You can dig down a bit… • Finally, carefully solder in between the studs like this – Polarity is going to matter… Soldering to the Railhead • Pick an area near a wire pass-through gap on the bottom edge of the track • Prepare your wire (cut and strip it) – Only one wire goes under the track… • Rough the area on the “outside”edge – Scratch with a scribe, or light steel wool • “Tin” the spot first, before you add wires – Only heat the outside edge, not the top Railhead Clues • Find the wire pass-through – Wires solder to the “outside edge”, below the top of the railhead so trains won’t derail – A dab of hot glue holds the wire • Only one wire needs to cross for a track power connection • (Only the white wire here…) What else can I hack? • Why tie up Track Power Controllers to power many models? • Make an adjustablevoltage power brick! – Add a 2x2 power brick (now you’ve done it!) – Stack a few models on this same power What about Mindstorms Stuff? • I’ve only hacked with the RCX bricks. – I’ve seen some interesting sensors. – I wanted to trigger train automation. • I tried optical sensors, but they are bulky, take up space Hide-A-Train Idea • I originally heard this at the set-up session for a Vancouver LTC display • Mix a Hogwarts train with freight train • Paced to leave the platform after the freight, and follow around the loop • Diverted to a hidden siding, to wait a random number of freight-loops & return What would you need? • Automated switch points (2) – Only divert from the main line to the siding! – Switches allow re-entry from the siding! • • • • • Isolated track power Gradual power to start the train Some type of sensors to say it is safe Sensors to say Hogwarts is parked A random-loop counter (Mindstorms) Magnetic Reed Switches • Two contacts enter the reed from opposite sides, meeting in the middle. • The reed works when opposites attract. – One contact must be North, one South • Where are the poles on your magnets? – Test your idea with a reed switch! – Which axis works the best? Testing the magnet axis issue • When trains are coupled the reed switch should be in-line with the track • But, the first and last couplers usually pivot 90 degrees! (The reed cannot sense them!) What is the best way? • I built a fixture to try all three axis’ – Adjustable positioning – Lights if the switch is tripped • Here’s the best axis to sense train couplers Building a Reed Switch sensor • All it takes to build a basic switch – LEGO 2x2 brick power connector (cut a cable?) – a pair of wires – small reed switch (no polarity) – A housing to keep the reed safe Solder the reed switch • Don’t clip the leads of the switch until you are done • Keep the cable leads short, and solder them close to the reed body • Test the switch with a meter, or an RCX – If it works, THEN you can clip the leads Build a safe enclosure • The switch will fit in between the studs • You need to trim 2 studs for the wires! • I use a thin router bit in the Dremel, but I’ve also used an Xacto hobby knife too. – Test-fit the switch before you proceed! Make the tiles to cover it… – Left: remove one edge of the tile, and part of the inside surface – Right: remove one edge, the center stud, part of the inside surface, and notch other edge Uses for the Reed Switches • Robot cows -> • Level crossing • Train pacing (block control) • Use a few in parallel, if it works • Use a resistor plate to save inputs Test-fit the tile covers • First try the tile that protects the cable and the reed. – Make adjustments as may be needed • Check the fit of the second tile – The reed it just a little taller than the space under the tiles, so you may need to grind the inside-edge of the tiles for a good fit – Seal with hot glue, or CA Track Power Isolation • Useful for “Block Control” of tracks • Controlled by hand or by Mindstorms! – Original train pacing project developed by Tony Pratkanis, using all-LEGO part for a BayLUG public display How Block Isolation works • Start with a normal loop of track, powered by a speed controller. – Now, electrically isolate one section of track from the loop (the red track) – When the train motor gets here, it stops because there is no power. – Add a switch, so you can apply the loop power when you want it to go… Step 1: Miniaturization! • I replaced the LEGO switch and track power connectors with a pair of Reed Relays • I would drive them with an RCX, or a 9-volt battery box – The reed relay is a reed switch with a wire coil wrapped around the reed switch. I built it onto a straight track • I used the micro-saw to make a gap • Hot glue to tack down the railhead • Set the relays back from the track, and kept the profile low, below the trains… Step 2: Make it simple! • Short structure • Self contained – To isolate the block, just add power. • Fail-Safe – No power? No isolation! Step 3: Make it reliable! • I soldered to the outside of the railhead (away from the flanges of the rail wheels) • I made sure the railhead was smooth and flat, so trains would not derail • I used a reed switch sensor to detect the passing trains instead of optical… Why is there only one cut? • I made one block power switch track. (The isolated section is to the right) • The other track simply has a micro-gap But how big is a Block? • The white building hides the RCX • The red tiles indicate the block limits Track Cleaning Tools • Even a Kleenex is a light abrasive… • You will eventually wear off the metal on the railhead if you clean your track • But track should be cleaned once in a while to preserve it’s service lifetime! L-Gauge Track Cleaning Cars • Centerline was first, Aztec was second. • Aztec bought Centerline, retired both! RCX Level Crossing Program • Basic flow is waiting for a passing train to get near the crossing – Start lights – Lower gate – Wait for train • Two of the process flows are pretty busy, moving the gates! • Two others do nothing! Thank you for attending! • I’ve very glad that you came to BbtB • Thanks for attending my talk • You can reach me at ; zonker@baylug.org