ADI

advertisement

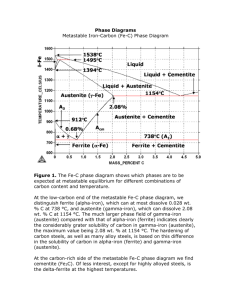

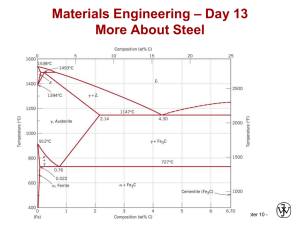

Foundry-Institut Basics of ADI (Heat treatment, structures, properties) Dr.-Ing. Claudia Dommaschk TU Bergakademie Freiberg, Germany 1 Introduction Definition according to ASTM A 644-92: „A ductile cast iron that has been produced by a controlled thermal process which consists of predominantly acicular ferrite and high carbon austenite“ Matrix: (Residual) Austenite Ferrite no carbides ADI and Bainite is not identic!!! The properties of ADI depend on the matrix and the nodule count and nodule shape. 2 Definitions Bainite = mainly acicular structure of Austenite, Ferrite and e-Carbides Ausferrite = mainly acicular ferrite and high-carbon austenite 5000:1 5000:1 Ausferrite Bainite α γ 3 Definitions Heat treatment between pearlite- and martensitic range Austenite Ausferrite Martensite Temperature Temperature Pearlite Bainite Time TTT-diagram for isothermal treatment of unalloyed cast steel Time 4 Heat treatment Aim: Transformation of the perlitic matrix into the austenitic-ferritic structur Base: Time-Temperature-Transformation diagram Austenite Temperature Pearlite Ausferrite Bainite Martensite Time 5 Influence parameter: Chemical composition Change of TTTdiagram caused by alloying with Cu and Ni 6 Heat treatment Austenitizing Heating up to a temperature range from 840 to 950 °C, holding for some hours for dissolving of perlitic matrix and C-saturation of austenite Austenite Attention! Holding time to low: Temperature Pearlite Residue pearlite degrades the material properties Ausferrite Bainite Martensite Time 7 Heat treatment Cooling: fast cooling to a temperature range from 230 to 450°C (in front of the pearlitic nose) Austenitic structure Austenite Attention! Cooling to low: Formation of Pearlite Temperature Pearlite Cooling to deep Formation of Martensite Ausferrite Bainite Martensite Time 8 Heat treatment Isothermal holding: Holding on constant temperature (230 ..... 450°C) Precipitation of ferrite splits, C-enrichment of austenite Stabilization of austenite Austenite Attention! Holding to long: Formation of Bainite Temperature Pearlite Holding to short: Residual austenite Ausferrite Bainite Martensite Time 9 Heat treatment Cooling to room temperature: Cooling to room temperature with optional cooling rate Austenite is stable to room temperature Austenite Temperature Pearlite Ausferrite Bainite Martensite Time 10 Effect of alloying elements: Example Molybdenum: Displacement of the Alloying up to 0.5 % Molybdenum offer a Temperature Pearlite- nose to the right lower cooling rate before isothermic holding Time 11 Stability of the structure: The ausferritic structure is thermodynamic instable - that means, it can disintegrate ! Thermal durability to appr. 300°C – above transformation into pearlite Limitation of using temperature of components Welding of components not possible Mechanical stability – stress introduced transformation into martensite (SITRAM) Attention during machining of castings 12 Structures ADI GJS-1000-5 orange = Austenite light = Austenite blue = Ferrite dark = Ferrite 13 Structures Carbides ADI GJS-800-8 Compound of austenite and ferrite 14 Properties of ADI Specific adjustment of properties High-strength and ductile material Very high-strength and wear resistant material but low ductility Temperature (°C) Using of a suitable heat treatment Time (h) 15 Comparison of ADI with GJL and GJS EN-GJL ADI EN-GJS 100 bis 350 800 bis 1400 320 bis 700* 98 bis 285 500 bis 1100 200 bis 400* (0,2%) 0,8 bis 0,3 8 bis 1 18 bis 1* Young´s Modulus kN/mm2 78 bis 143 165 bis 170 169 bis 176 Damping capacity very good good good Thermal conductivity W/(m.K) 43 bis 50 21 bis 22 31 bis 36 (300°C) N/mm2 Tensile strength min. Yield stress min. N/mm2 (0,1%) Elongation min. % (300°C) Machinability very good difficult good Castability very good very good very good 16 Tensile strength (Mpa) Properties of grey iron, ductile iron and ADI Elongation A5 (%) 17 Properties of ADI Hardness and abrasion resistant ... are determined by the ausferritic matrix High brinell hardness High tensile strength high abrasion resistant 18 Standardisation DIN EN 1564 Tensile Strength min. N/mm2 0.2 % yield stress min. N/mm2 Elongation % EN-GJS-800-8 800 500 6 bis 15 EN-GJS-1000-5 900 600 5 bis 12 EN-GJS-1200-2 1200 950 2 bis 5 EN-GJS-1400-1 1500 --- --- 19 Fields of application High strength components for the automotive engineering 304.8 m 3 0 4 .8 m m (1 2 in ) Crankshaft of steel (34,0 kg) Crankshaft for a sports car: ADI substitute steel 3 0 4 .8 m m (1 2 in ) Crankshaft of ADI (29,9 kg) 20 Fields of application 10-cylinderdiesel engine 1010 Carrier Plate, EN-GJS-800-8 21 Fields of application Horse shoe of ADI (source: ADI Treatments) 22 23 24