Motor - Bulk Molding Compounds, Inc.

advertisement

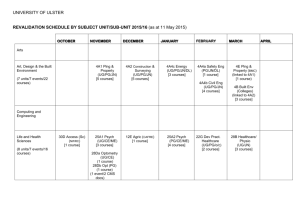

Bulk Molding Compounds, Inc. ‘Complete Composite Solutions’ BMC Injection- Molded Motor Bracket BMC vs. Die Cast Me ADVANTAGES • Reduced Cycle Times / Reduced Manufacturing Cost • Thermal / Dimensional Stability • Noise Reduction • Weight Reduction • Elimination of Costly Secondary Machining Operations • Lower Tooling Costs / Longer Tool Life • Greater Design Freedom = 30-50% Cost Savings over Die-Cast Metal Thermal / Dimensional Stability RIGIDITY AT ELEVATED TEMPERATURES BMC Composites vs. Engineering Thermosets Thermal / Dimensional Stability BMCs offer significant acoustical insulation over metals Automotive valve cover conversion from aluminum to BMC 25% Reduction in Valve-train noise in BMC ! Part Weight Reduction Part Weight Reduction Lower Specific-Gravity with BMC • BMC Polyester : 1.7 – 2.05s.g. • Die-Cast Aluminum : 2.6s.g. • Die-Cast Zinc : 6.9s.g. • Reduction In Assembly / Unit Weight • Lower Raw Material Content $ • Reduction in Shipping Weight / Cost $ No Secondary Machining • BMC Parts molded GATE FREE. No Secondary Gate Removal • No material overflows required for BMC. No secondary trim-die operation required • Critical dimensions / tolerances typically held as-molded. No secondary machining operations required. Package At Press Tooling Friendly BMC Polyesters are very “tooling-friendly” offering the following advantages over metals: • 4-5 Times Longer Mold Life • Higher Cavitations • Significantly lower PM & Repair Costs • Allows for use of more complex moving actions (Slides etc.) • Allows for use of manifold systems for material delivery to cavities Greater Design Freedom The flow characteristics and related moldability of BMCs allows for the formation of more complex part geometries. This gives the part designer increased freedom to: • Incorporate the net-shapes required to optimize the part / assembly design • Reduce the number of components through consolidation of parts Motor Bracket Configurations Commutator End Brackets / End Bells Fan End Brackets Clamshell Motors Motor End Plates “Cup” Style Motor Housings Fan / Diffuser End Caps Brush Plates Brush Cartridge Housings Commutator End Bracket / End Be • Integrated Brush Box Features • As-Molded Bearing Bore, Brush Boxes & Field Pads Fan End Brackets • Integrated Airflow Features • As-Molded Bearing Bore & Field Pads • Mounting Points Suitable for Motor Assembly Clamshell Motor Housings As-Molded Bearing Bore Advantages in Small HandHeld Applications Weight Reduction Noise / Vibration Reduction Ground-Path Insulation Motor End Plates • As-Molded Bearing Bore • Weight Reduction on Large Motor Configurations “Cup” Style Motor Housings • Reduced Number of Components in Assembly • More Consistent Motor Alignment • As-Molded Bearing Bore, Brush Boxes & Field Pads • Integrated Airflow Features Fan / Diffuser End Caps * Accommodates the formation of more complex / efficient airflow geometries Brush Plates / Cartridge Housings Superior Properties over Thermoplastics BMC Motor Bracket Materials BMC Materials currently supplied into motor bracket applications: BMC 400 BMC 620 BMC 1412 T40-(18) T40-(20) T40-(25) MCI can custom-formulate materials as-necessary to meet specific application Case Study #1 Commutator End Bracket Conversion Aluminum BMC Material Cost / Part: $.19 $.14 Molding Cost / Part: $.281 $.225 Secondary Gate Trimming: $.01 - Secondary Machining: $.035 - Scrap @ 3% $.015 $.011 Total Cost / Part: $.531 $.376 30% SAVINGS Case Study #2 Commutator End Bell Conversion/Redesign Brush Boxes incorporated into BMC part as 1-Piece Design Aluminum BMC Material Cost / Part: $.08 $.133 Molding Cost / Part: $.22 $.23 Secondary Gate Trimming: $.01 - Secondary Machining: $.035 - Scrap @ 3% $.001 $.011 Brush Plate (2nd Part): $.217 - Total Cost / Part: $.563 $.374 34% SAVINGS Mounting Hardware for BMCs Self-Tapping Screws Thread-Cutting Never Thread-Forming “BT”-Style or “Type-23” Style recommended High-Low thread preferred Hole diameter +.002” p/s over root-diameter of screw Minimum thread engagement 2 ½ X screw diameter Hole depth 125% to 150% of screw engagement depth Mounting boss diameter minimum 2X major screw diameter Design Considerations for BMC Minimum Recommended Wall Stock .070” Recommended Nominal Wall Stock .100” - .125” Minimum draft 1-degree P/S (Excluding Bores & Brush Boxes) Consistency of Wall stock Core-out Thick Sections Wherever Possible Fillet Radii Wherever Possible “Line-of-Draw Features Wherever Possible The BMC Advantage Faster Cycling Longer Tooling Life No Costly Secondary Machining Weight Reduction Noise Reduction Dimensional Stability Design Versatility BMC offers cost savings without sacrifice.