MD - Parksite

advertisement

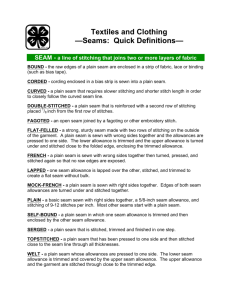

DuPont™ Corian® Private Collection Series Fabrication Considerations 2010 2 Private Collection Series Characteristics The Private Collection Series has characteristics that requires some specific fabrication methods • Directional veining that ranges from subtle to bold • The edge of the sheet has a different appearance than the top • The shade may change slightly through the thickness • Some colors have abrasive content that shortens tool life • Sheet yield may be lower – need to consider when quoting jobs It is important to understand these characteristics and be able to set customer expectations • Physical samples help in setting expectations 3 Veining Directional • Need to consider sheet orientation when seaming Random • Unless you have two consecutive sheets there will be a break in the pattern when seaming Edge appears different • Have side view of vein Veins vary through thickness • Cutting into sheet (rebating, coving) will reveal a different vein pattern Vein influence on background color stronger on the surface • Interior of sheet may have slightly different shade 4 Directionality Definitions • MD – Machine Direction (along length) • TD – Traverse Direction (along width) The veins generally run along the length (MD) Most uniform appearance is when all sections run the same direction Avoid MD-TD (90°) Butt Seams TD MD 5 Seaming Recommended 1 TD TD MD • (1) End to End (MD-MD) MD • Side to Side with same orientation • (2) MD-MD • TD-TD (not shown) TD 2 MD • (3) Miter Seam TD Not Recommended MD • (4) MD-TD Butt Seam 3 TD MD MD TD TD MD 4 MD TD 6 Mockup Contains: Mitered Seam MD-TD Seam MD-MD Seam Coved Backsplash Drop Edge Stack Edge V-Groove Edge 7 Mockup Contains: Mitered Seam MD-TD Seam MD-MD Seam Coved Backsplash Drop Edge Stack Edge V-Groove Edge 8 Mockup – Sorrel (Stronger Pattern) Contains: Mitered Seam MD-TD Seam MD-MD Seam Coved Backsplash Drop Edge Stack Edge V-Groove Edge 9 Edge Buildups top (1) V-groove Edge • “top” of sheet visible on both surfaces • Pattern can “flow” over edge • Good with minimal radius 1 edge (2) Stacked Edge • Edge of sheet visible, see edge of veins • Not identical to top of sheet, but “flows” • Works well with many profiles • May see “layers” (3) Drop Edge • • Side view has edge of top sheet, “top” of dropped edge Visible pattern difference for most Private Collection colors top 2 edge top 3 edge 10 Edge Buildups (1) V-groove Edge • “top” of sheet visible on both surfaces • Pattern can “flow” over edge • Good with minimal radius 1 (2) Stacked Edge • Edge of sheet visible, see edge of veins • Not identical to top of sheet, but “flows” • Works well with many profiles • May see “layers” 2 (3) Drop Edge • Side view has edge of top sheet, “top” of dropped edge • Visible pattern difference for many Private Collection colors 3 11 Coved Backsplashes Coves have two transitions in a short distance (deck-cove-backsplash) • There is a visual break in pattern • Some colors may appear a different shade in the cove • Veins may be more prominent in cove • Some colors with more subtle patterns may work • Best practice is to show customers physical samples to set expectations. 12 Alternate Corner Designs • Variations of Mitre corners • Stepped • Swooped • Fan • Alternatives to straight mitre • Must have proper seam support strip • Seam support strip must be supported properly • Seam support must be filled completely with adhesive • Higher cost to consumer helps to blend the pattern for better appearance 13 Alternate Corner Designs Stepped 14 Alternate Corner Designs Swoop 15 Alternate Corner Designs Fan 16 Other Considerations Some colors have ingredients that increase tool wear • Ecru, Cirrus White, & Natural Gray (Camel – Library Color) Private Collection colors can appear to be “softer” when finishing • Use care to get the proper finish Thermoforming • Heat to the lower end of the recommended range (150-160°C / 300-320°F) 17 Summary Private Collection colors have large scale patterns that require some extra considerations • Design and price with directionality in mind • Don’t base pricing on area and sheet price, yield may be lower to keep segments in the right orientation • Not all fabrication methods are suitable, those that work with subtle patterns may not work with bolder patterns • Some colors have abrasive content that shortens tool life Avoid surprises • It is important to understand these characteristics and be able to set customer expectations • Physical samples help in setting expectations 18 The information contained in this presentation is given by the E. I. du Pont de Nemours and Company free of charge. It is based on technical data which DuPont believes to be reliable and is intended for use by persons having knowledge of this technical area at their own discretion and risk. Seller assumes no responsibility for results obtained or damage incurred from the use of this presentation either in whole or in part by a buyer of DuPont™ Corian® solid surfaces. Copyright 2010 E.I. du Pont de Nemours and Company. DuPont™ Corian® is a registered trademark of E.I. du Pont de Nemours and Company