Yukon Wind Energy

advertisement

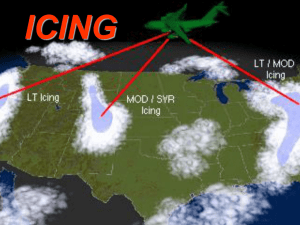

Yukon Wind Energy Wind Energy Research, Development and Operation in Harsh Arctic Environments For: International Wind-Diesel Workshop March 8-11, 2011 Girdwood, Alaska By John Maissan, P.Eng. and JP Pinard, PhD, P.Eng. 1 Introduction • • • • History of wind in Yukon Wind in mountainous terrain Icing and measurements Wind turbine operations in Yukon – The Bonus 150 kW – The Vestas V47 660 kW • Wind turbines in the north 2 History of Wind in Yukon • First wind measurements were made in 1980’s, results were negative. • Serious research began in the early 1990’s focused on mountaintops. • 1993 the Bonus 150 kW was installed with blade heating. • Wind program expanded to cover almost every community. • The Vestas V47 660kW was installed in 2000 • The wind research is ongoing... 3 Short Lesson on Wind in Mountainous Terrain • Inversions are a mainstay affecting wind with respect to height. • Winds in valleys are different from winds on mountaintops (geostrophic). • Winds are commercially better on mtn tops, however... icing 4 Northern Wind Climate: Stratification • The atmosphere is stability stratified • Air tends to flow in layers • Cold air sits at the valley bottom and is difficult to push along by air above • Air in valleys flow like rivers 5 Wind and Temperature profiles in a Yukon Valley Profiles from Whitehorse weather balloon station Haeckel Hill 6 JP Pinard photo JP Pinard photo JP Pinard photo 7 Northern Wind Climate: Seasonal variation • In winter larger temperature difference from equator to North pole • Means larger pressure difference -> windier. • Winds on the mountaintops tend to increase in the winter • However, Winds in the valleys tend to decrease in the winter: due to temperature inversion. 8 2400 m ASL: above the mountaintops When observing upper winds from this direction only 900 m ASL: within the valley Valley winds are like this Inversion in effect here From Pinard, 2007 7.9 m/s mean wind speed from this sector 9 Northern Wind Climate: wind pattern changes with height • Winds above mountaintops are typically geostrophic: they follow the pressure contours, high pressure to the right when facing downwind • Winds at mountaintops can be controlled by orography (mtn topography) • Winds within valleys tend to follow the valley axis. • Valley winds move from high pressure to low pressure areas. 10 LOW HIGH HIGH 2400 m ASL: above the mountaintops LOW LOW HIGH LOW HIGH From Pinard, 2007 11 Northern Wind Climate: Mountaintop icing • Icing is caused by supercooled water droplets: liquid water at 0 -> -20C temperatures. • Super-cooled water solidifies onto a solid surface. • Typically when there is a cloud at freezing temperatures, there is icing. • Mountaintops and coasts are prone to icing • Icing is worst in fall when air temperature drops below freezing and lakes still open. 12 John Maissan photo 13 Icing issues with measurements • • • • Icing can destroy met masts/towers Icing contaminates wind sensors Icing has been difficult to prevent Icing has been difficult to detect and measure 14 Icing on Towers • Ice can weight down heavily on the guy lines of a tower • Tower must support the added weight and vibration in high winds • Need tower tubes and guy wires of heavy gauge. • Lattice towers have more surface for ice to cling to. • Booms need to be sturdy 15 JP Pinard photo Yukon Energy photo 16 Icing on Sensors • • • • Ice contaminates sensors Ice throw can be damaging Plastic components of sensors can break Perceived wind speed is reduced under light icing and is hard to detect • Heavy icing is more obvious in data Yukon Energy photo JP Pinard photo 17 Anti-Icing on sensors • Need full body ice prevention • Heated portions of sensors can still be covered by icing stemming from non-heated part of the body • A variety of heated sensors with power requirements ranging from 75 to 1500 watts have been tried. • Power supply is a problem in remote locations: energy efficiency and management is critical • Need smaller sensor with less surface area to heat • To save energy use ice detector to detect icing and then turn on heated sensor. This causes problems with the sensor: eg. bearing issues. 18 Yukon Energy photo Yukon Energy photo Yukon Energy photo Yukon Energy photo Yukon Energy photo 19 Detecting Ice • Two heated anemometers: one is always on; the other is intermittent and comes on when slows. • Ice detector technology from aviation industry like the Goodrich (formerly Rosemount) Ice Detectors: models 0871LH1 (available today) and 0872B12 (better but no longer available) have been tested. • Ice detector technology is still in need of improvement • Need full body heating, however power is premium in remote sites • Need physically smaller instruments with less surface area, so that less power is required to heat and operate. 20 JP Pinard photo Yukon Energy photo Goodrich photo 21 Wind Turbine Operations in Yukon: The Bonus 150 kW installed in 1993 Special Features – low-temperature-tolerant steels (to -30°C) – synthetic lubricants – six-inch wide heaters for the leading edges of the blades – heating systems in the gearbox, generator and electronic cabinets – heated bearings for the wind vane and anemometer – hinged 30-metre tower capable of installation without a large crane Yukon Energy photo Yukon Energy photo Wind Turbine Operations in Yukon: The Bonus 150 kW installed in 1993 Challenges – Blade icing behind the heaters in severe icing conditions – The heated-bearing anemometer iced up – The two-section blades meant that the blade tip heaters often didn’t work, leading to icing and reduced output – Turbine shutdown when discrepancy between anemometer and power output Yukon Energy photo Yukon Energy photo Wind Turbine Operations in Yukon: The Bonus 150 kW installed in 1993 Solutions – Wider heaters were installed on leading edge to extend the ice free blade area – A black-coloured fluorourethane (StaClean) coating was applied to the blades to encourage ice shedding after warranty – Installation of fully heated anemometer and wind vane eliminated rime icing problems with them – Allow turbine to operate when power output below anemometer suggested output – right to nil Yukon Energy photo Wind Turbine Operations in Yukon: The Vestas V47 660kW, installed 2000 Features – Operation rated to -30C (“Arctic” version) – Pitch regulated – StaClean coated black blades – Twelve-inch heating strips for the blade leading edges – heating systems in the gearbox, generator and electronic cabinets – Shorter tower (37m) Yukon Energy photo Wind Turbine Operations in Yukon: The Vestas V47 660kW, installed 2000 Challenges – Still icing downstream of surface heaters – Turbine shutdown when power output below 75% of what it should be Solutions for Future – Full surface blade heating – Ice detector controlled blade heating – Allow turbine to operate at reduced output as long as no imbalance or vibration issues 20 10 0 -10 -20 OutdoorTemp NRG Icing -30 1-Jan-01 31-Jan-01 2-Mar-01 1-Apr-01 1-May-01 31-May-01 30-Jun-01 30-Jul-01 29-Aug-01 28-Sep-01 28-Oct-01 27-Nov-01 27-Dec-01 Icing and WTG Operations • Blade heating properly designed works – need commercial availability • Black surface works – assists in de-icing • Ice-phobic / hydro-phobic coatings appear to work • Rotor balance & vibration needs monitoring • Ice throw not a big issue with rime ice and in remote locations WTG in larger northern locations For northern industry or power grids • Scale is somewhat smaller than mainstream grid-connected systems. • Cranes are very expensive to deploy to remote locations • Wish list: – Optional operation to -40°C – Towers & nacelles that require reduced crane size – More selection in 300kW to 1MW turbines – Optional blade heating when required – Expanded remote operational and maintenance monitoring and control WTG in small remote communities • Scale is smaller than mainstream grid-connected systems • Cranes are very expensive to deploy to remote communities • Wish list: – Optional operation to -40°C & blade heating – Tilt up towers that require no crane – More selection in 50 – 150 kW turbines – Simple generator and blade designs – Cookie cutter foundation and electrical integration designs to reduce costs – Expanded remote operational and maintenance monitoring and control Thank You! This and other related publications can be found at http://www.esc.gov.yk.ca/publications_yukon.html 39