Best Practices for Asphalt Paving

advertisement

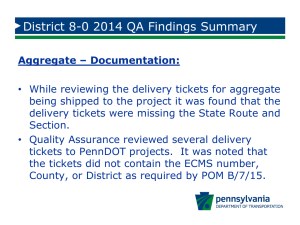

BEST PRACTICES for ASPHALT PAVING FIELD OPERATIONS BEST PRACTICES for ASPHALT PAVING FIELD OPERATIONS “Quality Means doing it right when no one is looking.” – Henry Ford PRE-PAVE PLANNING (Project Engineer / Paving Foreman) Check for availability of plant and material Specialized equipment needs: road widener, road grader, walk behind rollers, automatics, mobile reference, etc… Have plan if inclement weather might be encountered What is the Specified Tack Material Will a Necept certified technician be on site? Is a density gauge required? Have a plan for constructing & compacting the longitudinal joint? MOBILIZATION (Foreman / Equipment Manager) Equipment delivery ○ Proper equipment ○ Clean and serviced ○ Designated delivery area PRE-PAVING DAILY (Project Engineer / Paving Foreman) Daily Scheduling of Materials and Personnel Check existing conditions again of area to be paved that day Are we within surface & air temp requirements? Is surface preparation or cleaning necessary? Tack certification/rate/temp/break Verify application rate TACK APPLICATION (Driver / Paving Foreman) Have a properly calibrated distributer with a copy of certificate inside truck Adjust bars and nozzles to achieve proper width and rate Do not tack a larger area than can be protected Make sure tack is cured before paving over TACK APPLICATION (Driver / Paving Foreman) Do not tack a larger area than can be protected or paved over in the event of breakdown or inclement weather PAVER SETUP (Paving Foreman/MechanicEquipment Dept.) Lead crown Auger height/head of material control Feed speed Paving speed to match production Pre strike Angle of attack Paver Setup: Factors Effecting the Screed’s Performance Paver Speed Depth Crank Tow Point Head of Material Angle of Attack Pivot Point 1. Angle of Attack 2. Paving Speed 3. Head of Material 4. Material Workability PAVER SETUP (Paving Foreman/Mechanic-Equipment Dept.) Lead crown Auger height/head of material control Feed speed Paving speed to match production Pre strike Angle of attack Automatic/manual-depth & slope control Use of mobile reference/joint matcher, etc.. Use of auger extensions Establish a guide line for paver to follow PAVER SETUP PAVER SETUP SCREED WITHOUT VIBRATION 75 - 80% Gmm SCREED WITH VIBRATION 80-85% Gmm FIELD OPERATIONS Segregation: Paver Operation Control the Head of material ± 1” @ ½ auger Never allow material lower than the flow gates Prevent accumulation of material in the corners. No Wings Cycling if Hopper near Empty 4 steps Dumping Procedure 4 Screed hot spots No Spillage. Courtesy Caterpillar FIELD OPERATIONS 4 Potential Areas of Segregation: 1. Center drive 2. Quarter point 3. End Conveyors 4. Tunnel – Edger plates 3 1 2 Courtesy Ingersoll-Rand SEGREGATION CONTROL Possible Areas of Segregation: Elevator Hot Bins Silos Loading Pug Mill Dryer Stockpiles Cold feeds RELEASE AND FIRST LOAD (Paving Foreman) Check first ticket for proper information ○ Job Mix Formula (JMF) ○ Tonnage ○ Date ○ Temperatures Mix Design Asphalt Affidavit MIX DESIGN TRUCKS (Paving Foreman / Dump Foreman) Are they arriving on time and properly tarped? Have a Dump man or other designated ticket exchange person. Insure smooth pickup by paver/MTV Take initial and intermittent temperature checks in the field Have a designated clean out area GOOD NOT ACCEPTABLE FIELD QC on PAVING DAY (Field Technician, Paving Foreman, Operators) ○ Review the placement mix design ○ Review the sampling plan if there are cores/boxes to be taken ○ If a density gauge is required, has it been standardized? ○ Understand depth and width requirements and monitor during placement ○ Who will straightedge any transverse joints? FIELD QC on PAVING DAY (cont) (Paving Foreman Field Technician / Operator) Rolling Train ○ Check water systems on rollers ○ Set roller amplitude and frequency for given placement ○ Special requirements/techniques if rubber tire is in use ○ Set up initial rolling pattern with operators and monitor ○ Monitor density and temperature of mat ○ Monitor density and appearance of joints ○ Check appearance of mat finished product ○ Adjust rolling pattern as needed OPERATIONS: ROLLERS 3. Vibration • Amplitude • Frequency • Impact per Foot • Travel Speed Too Far Apart IPF = 12 Proper Spacing @ 2400 VPM - Travel Speed = VPM/IPF = 200 FPM @ 3600 VPM - Travel Speed = VPM/IPF = 300 FPM OPERATIONS: ROLLERS STATIC COMPACTION 1. Static Loading Pounds per Linear-Inch • Roller Weight • Drum width • Drum diameter 2. Kneading • Roller Weight • Tire Profile • Tire Pressure ROLLING TECHNIQUES (Field Tech / Paving Foreman / Operator) How to stop at end of pass ROLLING TECHNIQUES (Field Tech / Paving Foreman / Operator) How to deal with stoppages MATERIAL SAMPLING LOOSE BOXES (Field Technician) MATERIAL SAMPLING LOOSE BOXES (Field Technician) MATERIAL SAMPLING LOOSE BOXES (Field Technician) MATERIAL SAMPLING LOOSE BOXES (Field Technician) MATERIAL SAMPLING - CORES COMMUNICATIONS (All Responsible Parties) Paving Crew / Plant Within crew ○ Everyone has a responsibility and everyone needs to know what that is! ○ Foreman, Technicians, Mechanic, Operators RECORDKEEPING (All) Required paperwork for agency/owner In House Paperwork: ○ Density readings ○ Ambient and surface temps ○ Material temps ○ roller settings and # of passes, ○ troubleshooting, etc… (Build a solid database of information – know what works for any given situation) ROLLING PATTERN FORM SAFETY EDGE Courtesy of PennDOT LTAP SAFETY EDGE Courtesy of PennDOT LTAP SAFETY EDGE Courtesy of PennDOT LTAP SAFETY EDGE Courtesy of PennDOT LTAP Thank You! Greg Tomon Quality Control Field Manager Lindy Paving gtomon@lindypaving.com Courtesy ODOT