York Prestige Product Overview Nov 2013

advertisement

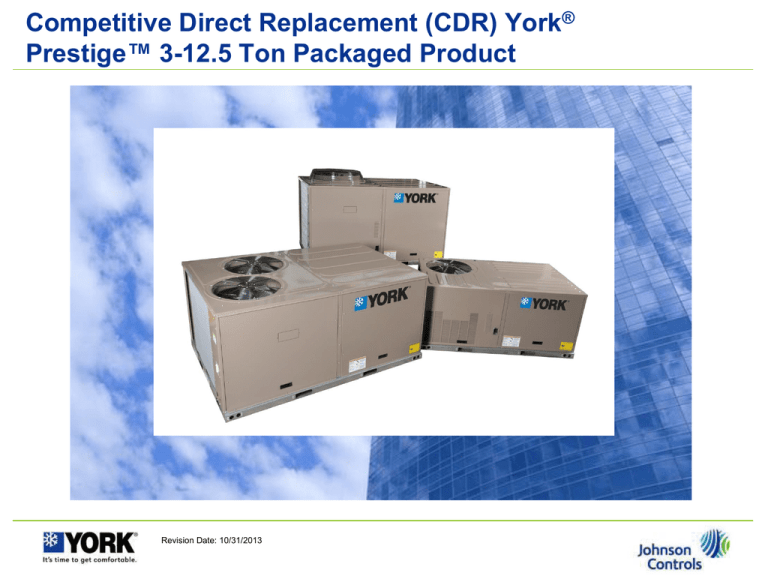

Competitive Direct Replacement (CDR) York® Prestige™ 3-12.5 Ton Packaged Product Revision Date: 10/31/2013 Presentation Agenda • York® PrestigeTM- CDR Rooftop – Competitive Direct Replacement Market Overview – The Replacement Opportunity – Present Situation- York, Carrier, Trane – Carrier Specifications – Product Basic Design Review – York Prestige versus Carrier Weathermaker (TC), Weathermaster (HC) • York PredatorTM 18+ SEER Rooftop (3-5 Ton) – Product Scope – Copeland Scrolls and Sine-Wave Coil – Variable Frequency Drive Market Overview and History Commercial Share of Market Others Lennox The commercial market is primarily replacement driven and requires a transition curb to replace competitors equipment Carrier JCI Trane Carrier & Trane have dominated the commercial market and have the largest installed base New Construction 27% 73% Replacement The Replacement Opportunity is Large & Getting Larger Shipment History 3-12T Packaged AC & HP's 100,000 4.3M Total Units Shipped 80,000 70,000 60,000 50,000 40,000 Replacement Opportunity 2010 75,000 units 2011 78,000 2012 80,000 2013 90,000 2014 95,000 2015Sales Carrier Historical 30,000 Installed base continues to grow 1.7M Units 20,000 10,000 Year 2010 2008 2006 2004 2002 2000 1998 1996 1994 1992 1990 1988 1986 1984 1982 1980 1978 1976 0 YEAR Est AHRI Units Shipped 90,000 Year Replacement peak began in 2010 for units originally installed in 1995 105,000 2016 110,000 2017 120,000 2018 125,000 2019 125,000 Present Situation = Transition Curb Required to replace Carrier/Bryant Product • • 6 -12T Transition Curb ~ $600 plus labor York must avoid a transition curb due to increased cost of materials and labor as well as some height restrictions Thus the requirement for a “direct” replacement in the 3 – 12T range York Prestige- Replacing Carrier Weathermaster-Salt Lake City, Utah May 2013 (5 Ton Gas/Electric Packaged Unit) Removal/Installation Carrier Unit Lift York Unit Lift York Prestige- Replacing Carrier Weathermaster-Salt Lake City, Utah May 2013 Carrier Unit Gas Connect York Unit Gas Connect York Prestige- Replacing Carrier Weathermaster-Salt Lake City, Utah May 2013 Fits perfectly on existing curb Gas, Electric and Drain are a exact alignment • • Goodman does not align as well Lennox is missing higher tonnages and mid tier efficiencies The big opportunity…to replace these with YORK units….coming soon, to markets near you! Notice the extensive corrosion on both the Carrier units louvers and base rails. Carrier’s pre-painted steel is unpainted in areas that are sheared (cut) thus exposing unpainted steel to the elements. Carrier’s units are tested per ASTM B117 salt spray testing to 500 hours. York products utilize a power coating process for paint thus fully coating all exposed surfaces with protective paint or galvanization. York’s units are tested per ASTM B117 salt spray testing to 1000 hours. The big opportunity…to replace these with YORK units….coming soon, to markets near you! • Notice the “New” Carrier units base-rail. Damaged already from transport and rigging. • York’s CDR (Competitive Direct Replacement) unit is equipped with heavier base rails to prevent this type of damage. • Notice the embossment on the York units top panel. Another reason to choose the durability and quality of the York RTU. Competition – Carrier, Bryant (Today) 3 to 12.5 Ton Rooftop Units • Two Tiers of efficiency 13 SEER/15 SEER (11 EER/12 EER) • Cooling & Heat Pump • Gas Heating & Electric Strip Heat (Acc) • Two footprints with two cabinet heights • Electro-mechanical controls with open protocol BAS option • Other options and accessories • Hail guard & Hinged panel options • Economizer & Damper options • Power & unpowered conv outlets • Disconnect switches • Smoke detectors & CO2 detectors • Coil coating options • Power exhaust accessory • Energy recovery vent accessory • Hot gas reheat option York Prestige to Carrier Conversion Table- No Curb Adapter Required!! York Prestige to Bryant Conversion Table- No Curb Adapter Required!! York Prestige to ICP Conversion Table- No Curb Adapter Required!! York Prestige Packaged Unit Product Offering – ASHRAE 90.1 Compliant Standard Efficiency Level Cooling W/Gas heat Nominal COOLING Tons 3 4 5 Performance Target STAGES Net MBH 1 Cooling W/Electric Heat 34.6 45.0 59.0 SEER EER Tons 13.0 13.0 13.0 11.0 11.0 10.75 3 Cooling W/Gas heat Nominal COOLING Tons 6 1 7.5 8.5 10 12.5 Performance Target STAGES Net MBH 2 Nominal COOLING EER IEER 70.0 11.0 11.2 83.0 11.0 11.2 99.0 11.0 11.2 114.0 11.0 11.2 140.0 10.8 11.0 4 5 Performance Target STAGES Net MBH 1 SEER EER 34.6 13.0 11.0 45.0 13.0 11.0 59.0 13.0 10.75 Cooling W/Electric Heat Nominal COOLING Performance Target Tons STAGES Net MBH EER IEER 1 70.0 11.2 11.4 6 83.0 11.2 11.4 7.5 99.0 11.2 11.4 8.5 2 114.0 11.2 11.4 10 140.0 11.0 11.2 12.5 Prestige Packaged Unit Product Offering – Energy Star Compliant MidTier Efficiency Level Cooling W/Gas heat Nominal COOLING Tons 4 Performance Target STAGES Net MBH 3 1 5 Cooling W/Electric Heat Nominal COOLING SEER EER Tons 36.0 15.0 12.0 3 48.5 15.0 12.0 4 57.5 15.0 12.0 5 Tons 6 1 7.5 8.5 10 Performance Target 2 1 Nominal COOLING EER IEER Tons 73.0 12.0 12.4 6 89.0 12.0 12.4 7.5 97.0 12.0 12.4 8.5 115.0 11.5 11.6 10 STAGES Net MBH STAGES Net MBH SEER EER 36.0 15.0 12.0 48.5 15.0 12.0 57.5 15.0 12.0 Cooling W/Electric Heat Cooling W/Gas heat Nominal COOLING Performance Target Performance Target STAGES Net MBH 1 2 EER IEER 73.0 12.2 12.6 89.0 12.2 12.6 97.0 12.2 12.6 115.0 11.7 11.8 Prestige Packaged Product Offering – Gas Heat Capacities Size (tons) 3 4 5 6 7.5 8.5 10 12.5 Entry Tier, 3-Phase Input Thermal Gas Stage 1 Stage 2 Efficiency Heat (MBH) (MBH) (%) Low 72 80+ Med 82 115 80+ High Low 72 80+ Med 115 80+ High 120* 150* 80+ Low 72 80+ Med 115 80+ High 120* 150* 80+ Low 72 80+ Med 115 80+ High 120* 150* 80+ Low 125 80+ Med 120 180 80+ High 180* 224 80+ Low 125 80+ Med 120 180 80+ High 180* 224 80+ Low 120 180 80+ Med 180 224 80+ High 200* 250* 80+ Low 120 180 80+ Med 180 224 80+ High 200* 250* 80+ Size (tons) 3 4 5 6 7.5 8.5 10 Gas Heat Low Med High Low Med High Low Med High Low Med High Low Med High Low Med High Low Med High Mid Tier, 3-Phase Input Stage 1 Stage 2 (MBH) (MBH) 50 72 82 115 50 72 82 115 120* 150* 50 72 82 115 120* 150* 50 72 90 125 105* 150* 90 125 120 180 180* 224 90 125 120 180 180* 224 120 180 180 224 200* 250* Thermal Efficiency (%) 80+ 80+ 80+ 80+ 80+ 80+ 80+ 80+ 80+ 80+ 80+ 80+ 80+ 80+ 80+ 80+ 80+ 80+ 80+ 80+ *Will not be available at initial production Prestige Product Brochure Prestige Product Details Key Advantages and Product Details Unit top panel and other cabinet panels are embossed to provide robust structural support Powder-coat paint finish will meet 1000 hour salt spray rating per ASTM B-117 Key Advantages and Product Details Base rails are thicker gauge to increase rigidity and reduce handling damage All units will be seismically rated to the highest levels per CBC 2010, IBC 2009, ICC-ES AC-156 2010, ASCE 7-05 Key Advantages and Product Details Condenser coils utilize Micro-Channel “allaluminum” condensers for improved heat transfer capabilities and reduced charge volumes. Evaporator coils utilize copper tube/aluminum fin design for proven reliability and performance. All units tested to 125°F ambient cooling operation ElectroFin® E-coat Coil coating option is available to protect against corrosion Key Advantages and Product Details Unit is shipped with 2 inch filters but can be field converted to 4 inch filters with no tools required Lower filter clips are rotated to expand filter rack to hold 4 inch filter Key Advantages and Product Details Simplicity® SE Controls (Smart Equipment Controls) – The next generation of unit based control of equipment FDD (Fault Detection and Diagnostics) Auto-Configuration Factory Configured/Tested Self Test and Startup Report Data Logging to Removable Memory (USB) Multi-Protocol Capability Energy Base-lining SMART Device Tools (MultiTouch) Plug and Play Feature Additions in the Field On board LCD Wireless Multi-Touch Device Prestige Packaged Unit’s Key Improvements over Carrier’s Product 1. SES1 Controls – Units will come with next generation control system standard. Carrier units are electro-mechanical as standard. 2. Cabinet structure – Unit top and side panels are embossed to provide increase structural support. Carrier product top and panels tend to sag and distort. 3. Seismic Testing – Units are specified to be OSP certified to a Sds of 2.5. Carrier’s product has a Sds of 2.0. 4. Units will be field convertible to 4” filters. Carrier is limited to 2”. 5. Microchannel condenser coils and reduced refrigerant charge. 6. Powder paint exterior finish with 1000 hour salt spray standard. Carrier uses pre-painted steel with 500 hour salt spray. 7. Economizers will meet low-leak requirements of ASHRAE 90.12010 and control will be integrated into unit system controls. 8. Units will be manufactured in U.S.A. (Norman, OK). Carrier produces commercial rooftop equipment in Monterrey, Mexico. Prestige Entry Level Efficiency Cabinet SizesENTRY-TIER CABINET SIZES • 2 footprint sizes • Each footprint has a short and tall cabinet • The tall version is 8” taller than the short version • The small footprint tall cabinet will be the same height as the large footprint short cabinet • 12.5 ton unit utilizes a single 30” condenser fan (not shown) Prestige Mid Level Efficiency Cabinet SizesMID-TIER CABINET SIZES • Mid-Tier version 4 & 5 ton moves to the tall cabinet of the small footprint. • The 6 ton moves to the large footprint short cabinet. • The 7.5 ton moves to the tall cabinet of the large footprint. • No 12.5 ton Mid-Tier offering - will not fit in the large footprint tall cabinet. Prestige Factory Options and/or Field Installed Accessories • Economizers – Bring in fresh air, outside air for ventilation; provide cool, outside air to cool the building. • CO2 Sensors – Sensor detect amount of CO2 in building and opens economizer accordingly. • Smoke Detectors (Supply Air and/or Return Air) – Shuts down unit when smoke is detected. • Louvered Hail Guards – Protects unit from Hail Damage, foreign objects, and incidental contact. • Convenience Outlet – 120V outlet for servicing the unit. • Non-fused Disconnect - Safety switch allows a service tech. to locally secure power to the rooftop. • Power Exhaust w/ Barometric Relief - Building pressure control. • Motorized 2-Position Damper - Motorized outdoor air damper admits up to 100% outside air. Prestige Factory Options and/or Field Installed Accessories • Manual Outdoor Air Damper – Economical way to bring in ventilation air (25% and 50% version) • Head Pressure Control/Low Ambient – Low ambient, head pressure controller kit. • Propane Heating – Converts rooftop to run off of propane. • High Altitude Heating – Restores the optimal fuel to air mixture for high altitude applications. • Flue Discharge Deflector – Used when flue gas recirculation is a concern. • Optional Stainless Steel Heat Exchanger – Used to fend against extreme airborne contaminants. • Flue Discharge Heat Shield – Used to keep people from touching hot flue discharge. • Alternate Motors and Drives – For more horsepower and/or airflow. • Thru-the-Base Connections – For piping or wiring up thru base pan (added protection or penetrations). Unitary Products Group 3-5 Ton Ultra High Efficiency Gas/Electric Packaged Product Revision Date: 5/17/13 Product Scope- 3-5 Ton Ultra High SEER Predator Packaged Unit • Offered in 3, 4, & 5 Ton Gas/Electric & Electric/Electric • Voltage 208/230/3 phase, 460/60/3 phase, & 575/60/3 phase – Competitive Product Efficiencies Tonnage Carrier Trane Lennox 3 Ton 17.1 SEER 17.5 SEER 18 SEER 4 Ton 17.5 SEER 17.5 SEER 17.6 SEER 5 Ton 17.2 SEER 17.2 SEER 17.1 SEER • York’s Ultra High SEER Predator Efficiencies Tonnage Efficiency 3 Ton 18.1 SEER/14.15 EER 4 Ton 18 SEER/14.35 EER 5 Ton 17.5 SEER/13.85 EER 31 Direct Drive vs. Belt Drive York’s Performance is Superior! Equipped with belt drive motor while competition has direct drive ECM Advantages: – Better control / Easy adjustment of airflow. – Higher ESP capabilities more than .5”wc ESP over the competition. – Puts the competition at more of an efficiency disadvantage when going to Belt drive – 10 to 17% more efficient than Carrier, 13 to 20% more efficient than Lennox, Trane does not publish belt drive impact. Competitive Efficiencies by Drive Type and Voltage Trane Carrier Tonnage 3 4 5 3 4 SEER (Btuh/Watt) - 208/230V-1-3ph 17.5 17.5 17.2 17.1 17.5 SEER (Btuh/Watt) - 460V-3ph, 575V-3ph Direct Drive EER (Btuh/Watt) - 208/230V-1-3ph 13 13 13 12.8 13.1 EER (Btuh/Watt) - 460V-3ph, 575V-3ph SEER (Btuh/Watt) - All Voltages N/A N/A N/A 15.5 16.4 Belt Drive EER (Btuh/Watt) - All Voltages N/A N/A N/A 12 12.6 5 17.2 12.7 16.2 12.3 3 18 17 12.7 12.5 15 11.6 Lennox 4 17.6 17 12.8 12.8 15 12.5 5 17.1 17 12.7 12.7 15.5 12.5 Compressor Technology used in the Ultra High SEER Predator • Copeland Scroll UltraTech 2.0™ Two-stage Scroll Compressor • The unit is equipped with Copeland’s Ultratech two speed scroll compressor technology that provides energy savings with excellent cooling and humidity control. • 1st stage will be utilized at part load conditions 33 High Efficiency Coils Used in the Ultra High SEER Predator • Sine Wave Evaporator –Sine wave fins improve the heat transfer factor and efficiency to a higher degree than standard corrugated fins. They also have a lower resistance to airflow. • MicroChannel Condenser – All Aluminum Design – Superior heat transfer / reduced size – Improved corrosion resistance – ~40% less refrigerant – Durable surface, resists damage 34 High Efficiency Motors along with VFD Used in the High SEER Predator • Premium Efficiency Indoor Motor – Inverter Rated – On slide-out assembly • ECM outdoor motors – Longer life than PSC – Energy savings • staged with demand 35 Variable Frequency Drive • All High SEER Predators will have a VFD as opposed to an ECM motor which brings with it – A five year warranty that can be redeemed directly from Mitsubishi. The ECM motor that is included with the competition’s high efficiency product will be included in the overall unit’s warranty which will most likely be 1 year. – Ease of Commissioning – Easy to read and program display right at the blower and with the ECM you must have a computer to program any airflow changes – Soft Start which equates to longevity of motor and belt life along with quieter operation and start-up. 36 Simplicity Intelli-Comfort II™ with IntelliSpeed™ used with the Ultra High SEER Predator • Intelli-Comfort II Standard • Econ and PE control • Uses Simplicity software • Modbus protocol or Optional BacNet (SimplicityLINC) • Humidity control • Holiday Scheduling • Minimum Air Monitoring Control 37 Other features and Benefits • Quiet Operation – Combination of outdoor ECM blower motors and swept wing fan is going to enhance the noise situation – VFD’s adjustable carrier frequency • Additional Energy Savings – Example: Annual $ savings at nominal: – A Building that has an average of 2,080 operating hours per year with $.11 cost per KW has the potential to save $150 per year when comparing a 4 ton belt drive Lennox to your new Ultra High Efficiency 4 ton unit 38 Agency/Standard Achievements • ASHRAE 90.1-2010 Compliant – Efficiencies – Single zone VAV requirement • LEED Credit 1 – Critical points could be achieved • EnergyStar – Efficiencies met • ASHRAE 189.1 Compliant 39 Ultra High Efficiency Gas/Electric Packaged Unit Color Brochure THANK YOU