Journal bearings

Chapter Outline

5.1 Introduction 169

5.2 Sliding bearings 171

5.2.1 Lubricants 175

5.3 Design of boundary-lubricated bearings 176

5.4 Design of full film hydrodynamic bearings 179

5.4.1 Reynolds equation derivation 184

5.4.2 Design charts for full-film hydrodynamic bearings 199

5.4.3 Alternative method for the design of full film hydrodynamic bearings 219

5.5 Conclusions 227

References 227

Websites 228

Standards 228

Further reading 230

Nomenclature

Generally, preferred SI units have been stated.

a

radius (m)

b

outer radius (m)

bo

characteristic length (m)

c

radial clearance (m)

D

journal diameter (m)

e

eccentricity

Eu

Euler number (dimensionless)

f

coefficient of friction

Fg

geometrical factor

Fr

Froude number (dimensionless)

Fx

body force component in the x direction (N/m3)

body force component in the y direction (N/m3)

Fy

Fz

body force component in the z direction (N/m3)

g

acceleration due to gravity (m/s2)

h

film thickness (m)

minimum film thickness (m)

ho

Ic

cosine load integral

Is

sine load integral

L

characteristic length, length (m), bearing length (m)

characteristic length (m)

lo

N

speed (normally in rpm)

Mechanical Design Engineering Handbook. https://doi.org/10.1016/B978-0-08-102367-9.00005-6

© 2019 Elsevier Ltd. All rights reserved.

5

168

Ns

p

pmax

P

qx

qy

Q

Qπ

Qs

r

rm

R

Re

Rex

Rey

Rez

S

SAE

t

to

t*

T

Tav

T1

T2

Ta

Tam

Tam,cr

ur

ux

ux,o

uy

uy,o

uz

uz,o

uϕ

u

Uo

V

W

x

x*

y*

z

z*

α

ε

ϕpmax

ϕho

Mechanical Design Engineering Handbook

journal speed (revolutions per second)

static pressure (Pa)

maximum annulus static pressure (N/m2)

load capacity (N/m2), load (N)

volumetric flow rate per unit width in the x direction (m2/s)

volumetric flow rate per unit width in the y direction (m2/s)

lubricant flow rate (m3/s)

flow through the minimum film thickness (m3/s)

side flow rate (m3/s)

radius (m)

mean radius (m)

specific gas constant (J/kg K)

Reynolds number (dimensionless)

Reynolds number based on x component of velocity (dimensionless)

Reynolds number based on y component of velocity (dimensionless)

Reynolds number based on z component of velocity (dimensionless)

geometrical factor, bearing characteristic number

Society of Automotive Engineers

time (s)

characteristic time scale (s)

dimensionless time ratio (dimensionless)

temperature (°C, K)

average temperature (°C)

temperature of the lubricant supply (°C)

temperature of the lubricant leaving the bearing (°C)

Taylor number (dimensionless)

Taylor number based on mean radius (dimensionless)

critical Taylor number based on mean annulus radius (dimensionless)

velocity component in the r direction (m/s)

velocity component in the x direction (m/s)

characteristic velocity component in the x direction (m/s)

velocity component in the y direction (m/s)

characteristic velocity component in the y direction (m/s)

velocity component in the z direction (m/s)

characteristic velocity component in the z direction (m/s)

velocity component in the tangential direction (m/s)

average velocity (m/s)

characteristic velocity (m/s), reference velocity (m/s)

journal velocity (m/s); velocity (m/s)

applied load (N)

distance along the x axis (m),

dimensionless location (dimensionless)

dimensionless location (dimensionless)

distance along the z axis (m)

dimensionless axial location (dimensionless)

angle (degree or rad)

eccentricity ratio

angular position of maximum pressure (degree)

angular position of minimum film thickness (degree)

Journal bearings

ϕpo

ϕ

169

ω

Ω

film termination angle (degree)

position of the minimum film thickness (degree), attitude angle (degree),

azimuth angle (rad)

relative azimuth angle (rad)

nondimensional circumferential location (dimensionless)

viscosity (Pa s)

reference viscosity (Pa s)

dimensionless viscosity (dimensionless)

kinematic viscosity (m2/s)

density (kg/m3)

dimensionless density (dimensionless)

reference density (kg/m3)

squeeze number (dimensionless)

viscous shear stress acting in the x direction, on a plane normal to the z direction

(N/m2)

viscous shear stress acting in the y direction, on a plane normal to the z direction

(N/m2)

angular velocity (rad/s)

angular velocity magnitude (rad/s)

5.1

Introduction

ϕ0

ϕ*

μ

μo

μ*

ν

ρ

ρ*

ρo

σs

τ zx

τ zy

The purpose of a bearing is to support a load, typically applied to a shaft, whilst allowing relative motion between two elements of a machine. The two general classes of

bearings are journal bearings, also known as sliding or plain surface bearings, and

rolling element bearings, sometimes also called ball-bearings. The aims of this chapter

are to describe the range of bearing technology, to outline the identification of which

type of bearing to use for a given application, and to introduce journal bearing design

with specific attention to boundary lubricated bearings and full film hydrodynamic

bearings. The selection and use of rolling element bearings is considered in Chapter 6.

The term ‘bearing’ typically refers to contacting surfaces through which a load is

transmitted. Bearings may roll or slide or do both simultaneously. The range of bearing types available is extensive, although they can be broadly split into two categories:

sliding bearings also known as journal or plain surface bearings, where the motion is

facilitated by a thin layer or film of lubricant, and rolling element bearings, where the

motion is aided by a combination of rolling motion and lubrication. Lubrication is

often required in a bearing to reduce friction between surfaces and to remove heat.

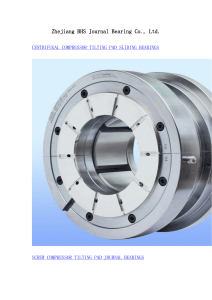

Fig. 5.1 illustrates two of the more commonly known bearings: a journal bearing

and a deep groove ball bearing. A general classification scheme for the distinction

of bearing types is given in Fig. 5.2.

As can be seen from Fig. 5.2 the scope of choice for a bearing is extensive. For a

given application it may be possible to use different bearing types. For example in a

small gas turbine engine rotating as say 50,000 rpm, either rolling bearings or journal

bearings could typically be used although the optimal choice will depend on a number

of factors such as life, cost and size. Fig. 5.3 can be used to give guidance for which

kind of bearing has the maximum load capacity at a given speed and shaft size and

170

Mechanical Design Engineering Handbook

Journal

bearing

Deep groove

ball bearing

Fig. 5.1 A journal bearing and a deep grove ball bearing.

Bearings for rotary motion

Sliding or journal bearings

Rolling bearings

Rolling element

Sliding bearings

Ball

Metallic

deep groove

spherical

self-aligning

Nonmetallic

Roller

Needle

Cylindrical

Taper

(Loading)

Axial

Boundary lubricated

(Lubrication)

(or support)

Radial

(Configuration)

Solid bushing

Mixed film

Barrel

Split bushing

Hydrodynamic

Hydrostatic

Magnetic

Fig. 5.2 Bearing classification.

Based on a taxonomy originally developed by Hindhede, U., Zimmerman, J.R., Hopkins, R.B.,

Erisman, R.J, Hull, W.C., Lang, J.D. Machine Design Fundamentals. A Practical Approach.

Wiley, 1983.

Table 5.1 gives an indication of the performance of the various bearing types for some

criteria other than load capacity.

This and the following chapter provide an introduction to bearings. Lubricant

film sliding bearings are introduced in Section 5.2, the design of boundary lubricated

Journal bearings

171

10,000,000

=5

00

D

mm

x

pro

Ap

D = 250

1,000,000

Hyd

r

bea odynam

ring

ic

s

D = 25

0 mm

m

m

Rolling

elem

bearing ent

s

D = 500

mm

xs

ma

D = 10

0m

m

co

D = 50

erc

50

ial

Approximate

maximum speed

of gas turbine

special ball

bearings

D

D=

10

mm

eel

mm

d st

D = 5 mm

m

soli

0 mm

ate

s

ng

ari

D=1

D=5

=2

5m

be

D = 10 mm

mm

xim

g

lin

rol

5 mm

ro

App

D=2

10,000

D=

mm

mm

D = 25 mm

1000

10

of

Typical maximum load (N)

D = 50 mm

ed

100,000

D=

pe

0 mm

=5

m

m

mit

rst li

Rubbing

plain

bearings

ft bu

sha

D

100

Plain bearings

10

0.01

0.1

1

10

100

1000

10,000

100,000

Speed (Revolutions per second)

Fig. 5.3 Bearing type selection by load capacity and speed.

Reproduced with permission from Neale, M.J. (ed.), 1995. The Tribology Handbook.

Butterworth Heinemann.

bearings which are typically used for low speed applications are considered in

Section 5.3, the design of full-film hydrodynamically lubricated bearings is described

in Section 5.4 and Chapter 6 considers rolling element bearings. For further reading

the texts by Khonsari and Booser (2017), Harris (2001) and Brandlein et al. (1999)

provide an extensive overview of bearing technologies.

5.2

Sliding bearings

The term sliding bearing refers to bearings where two surfaces move relative to each

other without the benefit of rolling contact. The two surfaces slide over each other and

this motion can be facilitated by means of a lubricant which gets squeezed by the

motion of the components and can generate sufficient pressure to separate them,

thereby reducing frictional contact and wear.

A typical application of sliding bearings is to allow rotation of a load-carrying

shaft. The portion of the shaft at the bearing is referred to as the journal and the stationary part, which supports the load, is called the bearing (Fig. 5.4). For this reason,

172

Table 5.1 Comparison of bearing performance for continuous rotation

Combined axial and

radial load

capability

Low starting

torque

capability

Silent

running

Standard

parts

available

Lubrication

simplicity

Rubbing plain

bearings

(nonmetallic)

Porous metal plain

bearings oil

impregnated

Fluid film

hydrodynamic

bearings

Hydrostatic bearings

Poor

Some in most cases

Poor

Fair

Some

Excellent

Good

Some

Good

Excellent

Yes

Excellent

Fair

No; separate thrust

bearing needed

Good

Excellent

Some

Excellent

Excellent

Excellent

No

Rolling bearings

Good

No; separate thrust

bearing needed

Yes in most cases

Very good

Usually

satisfactory

Yes

Usually requires a

recirculation

system

Poor special

system needed

Good when grease

lubricated

Bearing type

Reproduced with permission from Neale, M.J. (ed.), 1995. The Tribology Handbook. Butterworth Heinemann.

Mechanical Design Engineering Handbook

Accurate

radial

location

Journal bearings

173

Shaft

Journal

diameter

Bearing

diameter

Journal

Journal

Clearance

Bearing

material

Housing block

Fig. 5.4 A plain surface, sliding or journal bearing.

sliding bearings are often collectively referred to as journal bearings, although this

term ignores the existence of sliding bearings that support linear translation of components. Another common term frequently used in practice is plain surface bearings.

This section is principally concerned with bearings for rotary motion and the terms

journal and sliding bearing are used interchangeably.

There are three regimes of lubrication for sliding bearings:

(i) boundary lubrication,

(ii) mixed film lubrication,

(iii) full film lubrication.

Boundary lubrication typically occurs at low relative velocities between the journal

and the bearing surfaces and is characterised by actual physical contact. The surfaces,

even if ground to a low value of surface roughness, will still consist of a series of peaks

and troughs as illustrated schematically in Fig. 5.5. Although some lubricant may

be present, the pressures generated within it will not be significant and the relative

motion of the surfaces will bring the corresponding peaks periodically into contact.

Mixed film lubrication occurs when the relative motion between the surfaces is

Journal surface

Boundary

lubrication

Bearing surface

Journal surface

Mixed-film

lubrication

Bearing surface

Journal surface

Full film hydrodynamic

lubrication

Bearing surface

Fig. 5.5 A schematic representation of the surface roughness for sliding bearings and the

relative position depending on the type of lubrication occurring.

174

Mechanical Design Engineering Handbook

sufficient to generate high enough pressures in the lubricant film, which can partially

separate the surfaces for periods of time. There is still contact in places around the

circumference between the two components. Full film lubrication occurs at higher

relative velocities. Here the motion of the surface generates high pressures in the lubricant, which separate the two components and journal can ‘ride’ on a wedge of fluid.

All of these types of lubrication can be encountered in a bearing without external

pressuring of the bearing. If lubricant under high enough pressure is supplied to

the bearing to separate the two surfaces it is called a hydrostatic bearing (Rowe, 2012).

The performance of a sliding bearing differs markedly depending on which type of

lubrication is physically occurring. This is illustrated in Fig. 5.6, which shows the

variation of the coefficient of friction with a group of variables called the bearing

parameter which is defined by:

μN

P

(5.1)

where:

μ ¼ viscosity of lubricant (Pa s),

N ¼ speed (for this definition normally in rpm),

P ¼ load capacity (N/m2) given by

P¼

W

LD

(5.2)

W ¼ applied load (N),

L ¼ bearing length (m),

D ¼ journal diameter (m).

The bearing parameter, μN/P, groups several of the bearing design variables into one

number. Normally, of course, a low coefficient of friction is desirable to ensure that

only a small amount of power is necessary to rotate or drive the component concerned.

Fig. 5.6 Schematic representation of

the variation of bearing performance

with lubrication.

Coefficient of friction, F

II

I

Boundary

lubrication

II

Mixed film

lubrication

III

Hydrodynamic

lubrication

I

III

Bearing

parameter

µN/P

Journal bearings

175

Typical coefficients of friction for a boundary lubricated bearing are between approximately 0.05 and 0.1. By contrast the coefficient of friction for a rolling element bearing is typically of the order of 0.005.

In general, boundary lubrication is used for slow speed applications where the surface speed is less than approximately 1.5 m/s. Mixed-film lubrication is rarely used

because it is difficult to quantify the actual value of the coefficient of friction and

small changes in, for instance, the viscosity will result in large changes in friction

(note the steep gradient in Fig. 5.6 for this zone). The design of boundary-lubricated

bearings is outlined in Section 5.3 and full-film hydrodynamic bearings in Section 5.4.

5.2.1

Lubricants

As can be seen from Fig. 5.6 bearing performance is dependent on the type of lubrication occurring and the viscosity of the lubricant. The viscosity is a measure of a

fluid’s resistance to shear. Lubricants can be solid, liquid or gaseous although the most

commonly known are oils and greases. The principal classes of liquid lubricants are

mineral oils and synthetic oils. Their viscosity is highly dependent on temperature as

illustrated in Fig. 5.7. They are typically solid at –35°C, thin as paraffin at 100°C and

burn above 240°C. Many additives are used to affect their performance. For example

EP (extreme pressure) additives add fatty acids and other compounds to the oil, which

attack the metal surfaces to form ‘contaminant’ layers, which protect the surfaces and

10,000

2000

1000

300

200

Viscosity (mPa s)

100

40

30

SA

E

SA 60

E

5

SA 0

E

4

SA 0

E

30

SA

E

20

20

10

SAE 60, ISO VG 320

SAE 50, ISO VG 220

SAE 40, ISO VG 150

SAE 30, ISO VG 100

SA

7

6

5

E

IS

O

IS

O

4

10

VG

VG

32

SAE 20, ISO VG 68

22

3

SAE 10, ISO VG 46

ISO VG 32

ISO VG 22

2

10

20

30

40

50

60

70

80 90 100

130

Temperature (°C)

Fig. 5.7 Variation of absolute viscosity with temperature for various lubricants.

176

Mechanical Design Engineering Handbook

reduce friction even when the oil film is squeezed out by high contact loads. Greases

are oils mixed with soaps to form a thicker lubricant that can be retained on surfaces.

The viscosity variation with temperature of oils has been standardised and oils are

available with a class number, for example SAE 10, SAE 20, SAE 30, SAE 40, SAE

5 W and SAE 10 W. The origin of this identification system developed by the Society

of Automotive Engineers was to class oils for general-purpose use and winter use, the

‘W’ signifying the latter. The lower the numerical value, the thinner or less viscous the

oil. Multigrade oil (e.g. SAE 10 W/40) is formulated to meet the viscosity requirements of two oils giving some of the benefits of the constituent parts. An equivalent

identification system is also available from the International Organisation for Standardisation (ISO 3448).

5.3

Design of boundary-lubricated bearings

As described in Section 5.2, the journal and bearing surfaces in a boundary lubricated

bearing are in direct contact in places. These bearings are typically used for very low

speed applications such as bushes and linkages where their simplicity and compact

nature are advantageous. Examples include household lawnmower wheels, garden

hand tools such as shears, ratchet wrenches and domestic, automotive door hinges

incorporating the journal as a solid pin riding inside a cylindrical outer member

and even for cardboard wheels (Fig. 5.8). A further example, involving linear motion

is the slider in an ink jet printer.

General considerations in the design of a boundary lubricated bearing are:

l

l

l

l

l

l

the coefficient of friction (both static and dynamic),

the load capacity,

the relative velocity between the stationary and moving components,

the operating temperature,

wear limitations and

the production capability.

Fig. 5.8 The Move-it wheel for box transportation—Courtesy of Move-it.

Journal bearings

177

A useful measure in the design of boundary-lubricated bearings is the PV factor (load

capacity peripheral speed), which indicates the ability of the bearing material to

accommodate the frictional energy generated in the bearing. At the limiting PV value

the temperature will be unstable and failure will occur rapidly. A practical value for

PV is half the limiting PV value. Values for PV for various bearing materials are given

in Table 5.2, and Lancaster (1971), Yamaguchi and Kashiwagi (1982), and Koring

(2012). The preliminary design of a boundary-lubricated bearing essentially consists

of setting the bearing proportions, its length and its diameter, and selecting the bearing

material such that an acceptable PV value is obtained. This approach is set out step-bystep in Table 5.2.

Example 5.1. A bearing is to be designed to carry a radial load of 700 N for a shaft of

diameter 25 mm running at a speed of 75 rpm (Fig. 5.9). Calculate the PV value and by

comparison with the available materials listed in Table 5.3 determine a suitable bearing material.

Solution

The primary data are W ¼ 700 N, D ¼ 25 mm and N ¼ 75 rpm.

Use L/D ¼ 1 as an initial suggestion for the length to diameter ratio for the bearing.

L ¼ 25 mm.

Calculating the load capacity, P

W

700

¼

¼ 1:12 MN=m2

LD 0:025 0:025

2π

D

0:025

N ¼ 0:1047 75

¼ 0:09816 m=s

V ¼ ωr ¼

60

2

2

P¼

PV ¼ 0:11 MN=m2 ðm=sÞ

Multiplying this by a factor of 2 gives PV ¼ 0.22 (MN/m s).

A material with PV value greater than this, such as filled PTFE (limiting PV value

up to 0.35), or PTFE with filler bonded to a steel backing (limiting PV value up to

1.75), would give acceptable performance.

Example 5.2. The paper feed for a photocopier is controlled by two rollers which are

sprung together with a force of approximately 20 N. The rollers each consist of a

20 mm outer diameter plastic cylinder pressed onto a 10 mm diameter steel shaft

(Fig. 5.10). The maximum feed rate for the copier is 30 pages per minute. Select bearings to support the rollers (After IMechE, 1994).

Solution

The light load and low speed, together with the requirement that the bearings should

be cheap, clean and maintenance free suggest that dry rubbing bearings be considered.

The length of A4 paper is 297 mm.

The velocity of the roller surface is given by:

Vroller ¼

30 0:297

¼ 0:1485ms1 :

60

178

Mechanical Design Engineering Handbook

Table 5.2 Step-by-step guideline for boundary lubricated bearing design

Start Selection

Determine rotational speed

Determine the speed of rotation of the

bearing. This information may set by the

designer or defined by the specification.

OK

Determine the load to be supported

OK

No

Select L/D

OK

Determine the load to be supported. This

information may set by the designer or

defined by the specification.

No

Calculate the load capacity, P

Set the bearing proportions. Common

practice is to set the length to diameter

ratio between 0.5 and 1.5. If the diameter

is known as an initial trial set L equal to D

Calculate the load capacity, P=W/LD.

OK

Calculate V

Determine the maximum tangential speed

of the journal, V=w r.

OK

Calculate the PV factor

Calculate PV

OK

Select a factor of safety, SF

OK

Determine a factor of safety (SF) based on

knowledge of certainty of the operating

conditions. For general uncertainty a

factor of safety of 2 is normally adequate.

Multiply the PV factor obtained by the

factor of safety

Calculate SF PV

OK

Select a bearing material

OK

Complete

No

Interrogate manufacturer’s data for

bearing materials to identify an

appropriate bearing material with a value

of PV greater than (SF PV)

Journal bearings

179

Ø25

700 N

Fig. 5.9 Boundary lubricated bearing design example (dimensions in mm).

The angular velocity of the rollers is 0.1485/0.01 ¼ 14.85 rad/s.

The velocity of the bearing surface is therefore.

V ¼ 14:85 0:005 ¼ 0:07425m=s:

An L/D ratio of 0.5 could be suitable giving a bearing length of 5 mm. The load capacity is:

W

20

¼

¼ 0:4 MPa::

LD 0:005 0:01

PV ¼ 0:4 0:07425 ¼ 0:0297 MNm2 ms1 :

P¼

For this low value of PV the cheapest bearing materials, thermoplastics are

adequate.

5.4

Design of full film hydrodynamic bearings

In a full film hydrodynamic bearing, the load on the bearing is supported on a continuous film of lubricant so that no contact between the bearing and the rotating journal

occurs. The motion of the journal inside the bearing creates the necessary pressure to

support the load, as indicated in Fig. 5.11. Hydrodynamic bearings are commonly

found in internal combustion engines for supporting the crankshaft, and in turbocharger applications to support the rotor assembly (Fig. 5.12). Hydrodynamic bearings

can consist of a full circumferential surface or a partial surface around the journal

(Fig. 5.13).

Bearing design can involve so many parameters that it is a challenge to develop an

optimal solution. One route towards this goal would be to assign attribute points to

each aspect of the design and undertake an optimisation exercise using multiobjective

design optimisation or a similar scheme (Hashimoto and Matsumoto, 2001; Hirania

and Suh, 2005). This can however be time consuming if the software was not already

in a developed state and would not necessarily produce an optimum result due to inadequacies in modelling and incorrect assignment of attribute weightings. An alternative

180

Table 5.3 Characteristics of some rubbing materials

Material

Limiting

PV value

(MN/m S)

Maximum

operating

temperature

(°C)

1.4–2

0.11

350–500

3.4

0.145

130–350

70

0.28–0.35

2

Coefficient

of friction

Coefficient

of expansion

(×1026/°C)

Comments

Typical

application

For continuous

dry operation

Food and textile

machinery

0.1–0.25

dry

0.1–0.35

dry

2.5–5.0

350–600

0.1–0.15

dry

12–13

0.35

250

0.13–0.5

dry

3.5–5

35

0.35

200

0.1–0.4 dry

25–80

Roll-neck

bearings

10

0.035

100

0.1–0.45

dry

100

Bushes and

thrust washers

10–14

0.035–0.11

100

0.15–0.4

dry

80–100

Bushes and

thrust washers

4.2–5

Suitable for sea

water operation

Mechanical Design Engineering Handbook

Carbon/

graphite

Carbon/

graphite with

metal

Graphite

impregnated

metal

Graphite/

thermosetting resin

Reinforced

thermosetting

plastics

Thermoplastic

material

without filler

Thermoplastic with

filler or

metal backed

Maximum

load

capacity

P(MN/m2)

140

0.35

105

0.2–0.35

dry

27

With initial

lubrication

only

Filled PTFE

7

Up to 0.35

250

0.05–0.35

dry

60–80

Glass, mica,

bronze,

graphite

PTFE with

filler,

bonded to

steel backing

140

Up to 1.75

280

0.05–0.3

dry

20

Woven

PTFE

reinforced

and bonded

to metal

backing

420

Up to 1.6

250

0.03–0.3

–

Sintered bronze

bonded to steel

backing

impregnated

with PTFE/lead

Reinforcement

may be

interwoven

glass fibre or

rayon

For conditions of

intermittent

operation or

boundary

lubrication (e.g.

ball joints,

suspension,

steering)

For dry

operations where

low friction and

wear required

Aircraft controls,

linkages,

gearbox, clutch,

conveyors,

bridges

Aircraft and

engine controls,

linkages, engine

mountings,

bridge bearings

Journal bearings

Thermoplastic

material with

filler bonded

to metal back

Reproduced with permission from Neale, M.J. (ed.), 1995. The Tribology Handbook. Butterworth Heinemann.

181

182

Mechanical Design Engineering Handbook

Steel shaft

Plastic cylinder

Fig. 5.10 Copier rollers.

Reproduced from Institution of Mechanical Engineers, 1994. Tribological Design Data. Part 1:

Bearings. I. Mech. E.

W

N

e

r

h

Øp

o

Øho

o

Øpmax

Film

pressure, p

pmax

Fig. 5.11 Motion of the journal generates pressure in the lubricant separating the two surfaces.

Beyond ho, the minimum film thickness, the pressure terms go negative and the film is ruptured.

Fig. 5.12 Turbocharger journal.

Journal bearings

183

Fig. 5.13 Partial surface

journal bearings.

approach which is sensible as a starting point and outlined here is to develop one or a

number of feasible designs and use judgement to select the best, or combine the best

features of the proposed designs.

The design procedure for a journal bearing, recommended here as a starting point,

includes specification of the:

l

l

l

l

l

l

journal radius, r;

radial clearance, c;

axial length of the bearing surface, L;

type of lubricant and its viscosity, μ;

journal speed, N;

load, W.

Values for the speed, the load and possibly the journal radius are usually specified by

the machine requirements, and stress and deflection considerations. As such, journal

bearing design consists of the determination of the radial clearance, the bearing length

and the lubricant viscosity. The design process for a journal bearing is usually iterative. Trial values for the clearance, the length and the viscosity are chosen, various

performance criteria calculated and the process repeated until a satisfactory or

optimised design is achieved. Criteria for optimisation may be minimising of the

frictional loss, minimising the lubricant temperature rise, minimising the lubricant

supply, maximising the load capability, and minimising production costs.

The clearance between the journal and the bearing depends on the nominal diameter of the journal, the precision of the machine, surface roughness and thermal

expansion considerations. An overall guideline is for the radial clearance, c, to be

in the range 0.001r < c < 0.002r, where r is the nominal bearing radius

(0.001D < 2c < 0.002D). Fig. 5.14 shows values for the recommended diametral

clearance (2 c) as a function of the journal diameter and rotational speed for steadily

loaded bearings.

For a given combination of a, c, L, μ, N and W, the performance of a journal bearing

can be calculated. This requires determining the pressure distribution in the bearing,

the minimum film thickness ho, the location of the minimum film thickness θpmax, the

coefficient of friction f, the lubricant flow Q, the maximum film pressure pmax and

the temperature rise ΔT of the lubricant.

The pressure distribution in a journal bearing (Fig. 5.11) can be determined by solving the relevant form of the Navier–Stokes fluid flow equations, which in the reduced

form for journal bearings is called the Reynolds equation, Eq. (5.3).

∂ h3 ∂p

∂ h3 ∂p

∂h

∂V

+

¼ 6V + 6h

∂x μ ∂x

∂z μ ∂z

∂x

∂x

(5.3)

184

Mechanical Design Engineering Handbook

22

6000

5000

250 µm

5

20

0

3000

µm

4000

µm

17

5

µm

15

2000

0

µm

µ

75

µm

0

10

µm

800

700

600

500

50

m

Speed (rpm)

µm

5

12

1000

400

300

200

25 µm

100

80

70

60

25

50

75

100

125

150

175

200

Journal: diameter (mm)

Fig. 5.14 Minimum recommended values for the diametral clearance (2 c) for steadily

loaded journal bearings.

Reproduced with permission from Welsh, R.J., 1983. Plain Bearing Design Handbook.

Butterworth.

where:

h ¼ film thickness (m);

μ ¼ dynamic viscosity (Pa s);

p ¼ fluid pressure (Pa);

V ¼ journal velocity (m/s);

x, y, z ¼ rectangular coordinates (m).

The Reynolds equation was first derived by Reynolds (1886) and further developed by

Harrison (1913) to include the effects of compressibility. Here the derivation of the

general Reynolds equation is given in Section 5.4.1 and is developed following the

general outline given by Hamrock (1994) and Childs (2011). Many readers may prefer

to omit detailed consideration of the derivation as there is no need to go through

this for practical design applications and instead proceed directly to Section 5.4.2.

Nevertheless the derivation is included here for reference.

5.4.1

Reynolds equation derivation

The Navier–Stokes equations in a Cartesian coordinate system, for compressible flow

assuming constant viscosity are given by Eqs (5.4)–(5.6). Here x is taken as the coordinate in the direction of sliding, y is the coordinate in the direction of side leakage and

z is the coordinate across the lubricant film.

Journal bearings

185

ρ

2

∂ux

∂ux

∂ux

∂ux

∂p

∂ ux ∂2 ux ∂2 ux

+ ux

+ uy

+ uz

¼ +μ

+

+

+

∂t

∂x

∂y

∂z

∂x2

∂y2

∂z2

∂x

μ ∂ ∂ux ∂uy ∂uz

+

+

+ Fx

∂y

∂z

3 ∂x ∂x

(5.4)

2

∂uy

∂uy

∂uy

∂uy

∂ uy ∂2 uy ∂2 uy

∂p

+

+ ux

+ uy

+ uz

¼ +μ

+

+

∂t

∂x

∂y

∂z

∂x2

∂y2

∂z2

∂y

μ ∂ ∂ux ∂uy ∂uz

+

+

+ Fy

∂y

∂z

3 ∂y ∂x

(5.5)

ρ

ρ

2

∂uz

∂uz

∂uz

∂uz

∂p

∂ uz ∂2 uz ∂2 uz

+ ux

+ uy

+ uz

¼ +μ

+

+

+

∂t

∂x

∂y

∂z

∂x2

∂y2

∂z2

∂z

μ ∂ ∂ux ∂uy ∂uz

+

+

+ Fz

∂y

∂z

3 ∂z ∂x

(5.6)

If the density is assumed constant then the dilation (Eq. 5.7) is zero.

∂ux ∂uy ∂uz

+

+

¼0

∂x

∂y

∂z

(5.7)

The Navier–Stokes equations for constant density and constant viscosity reduce to

2

∂ux

∂ux

∂ux

∂ux

∂p

∂ ux ∂2 ux ∂2 ux

+ ux

+ uy

+ uz

¼ +μ

+ Fx

+

+

∂t

∂x

∂y

∂z

∂x2

∂y2

∂z2

∂x

(5.8)

2

∂uy

∂uy

∂uy

∂uy

∂ uy ∂2 uy ∂2 uy

∂p

+ ux

+ uy

+ uz

¼ +μ

+ 2 + 2 + Fy

ρ

∂t

∂x

∂y

∂z

∂x2

∂y

∂z

∂y

(5.9)

2

∂uz

∂uz

∂uz

∂uz

∂p

∂ uz ∂ 2 uz ∂ 2 uz

+ ux

+ uy

+ uz

¼ +μ

+ 2 + 2 + Fz

ρ

∂t

∂x

∂y

∂z

∂x2

∂y

∂z

∂z

(5.10)

ρ

For conditions known as slow viscous motion, where pressure and viscous terms predominate simplifications are possible for the Navier–Stokes equations making their

solution more amenable to analytical and numerical techniques.

The Navier–Stokes equations can be nondimensionalised to enable a generalised

solution (Childs, 2011). Here the process is repeated to give dimensionless groups

of specific relevance to journal bearings using the characteristic parameters given

in Eqs (5.11)–(5.20).

x∗ ¼

x

lo

where lo is a characteristic length in the x direction.

(5.11)

186

Mechanical Design Engineering Handbook

y

bo

y∗ ¼

(5.12)

where bo is a characteristic length in the y direction.

z

ho

z∗ ¼

(5.13)

where ho is a characteristic length in the z direction.

t∗ ¼

t

to

(5.14)

where to is a characteristic time.

ux* ¼

ux

ux, o

(5.15)

where ux,o is a characteristic velocity in the x direction.

uy* ¼

uy

uy, o

(5.16)

where uy,o is a characteristic velocity in the y direction.

uz* ¼

uz

uz, o

(5.17)

where uz,o is a characteristic velocity in the z direction.

ρ∗ ¼

ρ

ρo

(5.18)

where ρo is a characteristic density.

μ∗ ¼

μ

μo

(5.19)

where μo is a characteristic viscosity.

p∗ ¼

h2o p

μo ux, o lo

(5.20)

Substitution of the above dimensionless parameters, Eqs (5.11)–(5.20) in Eq. (5.4),

gives

Journal bearings

187

2

lo uy,o

lo ∂ux*

∂u

∂u

lo uz, o

∂u

lo g

μo

lo

1 ∂p∗

+ ux* x* +

uy* x* +

uz* x* ¼ 2 ux, o to ∂t∗

∂x∗ bo ux, o

∂y* ho ux,o

∂z∗ ux,o ρo ux,o lo ho ρ∗ ∂x∗

2 μo 1 ∂

∂ux* uy,o lo ∂uy* uz,o lo ∂uz*

2μo 1 ∂

∂ux*

+

+

μ∗

+

+

μ∗

∂x∗ ux, o bo ∂y∗ ux,o ho ∂z∗

ρo ux,o lo ρ∗ ∂x∗

∂x∗

3 ρo ux,o lo ρ∗ ∂x∗

2

2

μo

lo

1 ∂

∂ux* uy, o bo ∂uy*

μo

lo

1 ∂

∂ux* uz,o ho ∂uz*

μ∗

+

μ∗

+

+

ρo ux, o lo bo ρ∗ ∂y∗

∂y∗ ux, o lo ∂x∗

ρo ux,o lo ho ρ∗ ∂z∗

∂z∗ ux, o lo ∂x∗

(5.21)

The relative importance of inertia and viscous forces can be determined by examination of the value of the Reynolds number

ρ ux, o lo

Re ¼ o

μo

(5.22)

The inverse of the Reynolds number occurs throughout Eq. (5.21).

In fluid film lubrication, because of the dominance of the viscous term ∂2ux∗/∂2z∗, a

modified form of the Reynolds number is used, defined for the x component of

velocity by

ρ ux, o h2o

Rex ¼ o

μo lo

(5.23)

and similarly for the y and z directions

ρ uy, o h2o

Rey ¼ o

μ o bo

(5.24)

ρ uz, o ho

Rez ¼ o

μo

(5.25)

The squeeze number is defined by

ρ h2

σs ¼ o o

μo to

(5.26)

Typically in hydrodynamically lubricated journal bearings, viscous forces are much

greater than inertia forces and a typical Reynolds number, using Eq. (5.23), might be

of the order of 1 104.

Substitution of the Reynolds and squeeze numbers into Eq. (5.21), gives

188

Mechanical Design Engineering Handbook

∂ux*

∂ux*

∂ux*

∂ux* lo g

1 ∂p∗ 1 ∂

∂ux*

+ Rex ux*

+ Rey uy*

+ Rez uz*

¼ 2 Rex +

μ∗

∂t∗

∂x∗

∂y∗

∂z∗ ux, o

∂z∗

ρ∗ ∂x∗ ρ∗ ∂z∗

2 ho 2 1 ∂

∂ux* uy,o lo ∂uy* uz, o lo ∂uz*

μ∗

+

+

+

∂x∗ ux, o bo ∂y∗ ux, o ho ∂z∗

3 lo ρ∗ ∂x∗

2

2

ho 1 ∂

∂ux* uy, o bo ∂uy*

ho 1 ∂

∂u

1 ∂

uz, o ho ∂uz*

μ∗

+

μ∗ x* +

μ∗

+2

ρ∗ ∂z∗

bo ρ∗ ∂y∗

∂y∗ ux, o lo ∂x∗

lo ρ∗ ∂x∗

∂x∗

ux, o lo ∂x∗

σs

(5.27)

Examination of the order of magnitude of the terms in Eq. (5.27) provides an indication of the relative significance of the terms and which need to considered. The inertia

terms, gravity term and uz,o/ux,o are of order ho/lo. The pressure gradient term and the

first viscous term are of order unity. The remaining viscous terms are of order (ho/lo)2

or (ho/bo)2 and therefore very small in comparison to the other terms. Neglecting terms

of the order of (ho/lo)2 and (ho/bo)2 gives

∂ux*

∂ux*

∂ux*

∂ux*

+ Rex ux*

+ Rey uy*

+ Rez uz*

∂t∗

∂x∗

∂z∗

∂y∗

lo g

1 ∂p∗ 1 ∂

∂ux*

¼ 2 Rex +

μ

ux, o

ρ∗ ∂x∗ ρ∗ ∂z∗ ∗ ∂z∗

σs

(5.28)

Similarly for the y and z components

∂uy*

∂uy*

∂uy*

∂uy*

+ Rex ux*

+ Rey uy*

+ Rez uz*

∂t∗

∂x∗

∂y

∂z∗

∗

∂uy*

bo g

1 ∂p∗ 1 ∂

¼ 2 Rey +

μ

uy, o

ρ∗ ∂y∗ ρ∗ ∂z∗ ∗ ∂z∗

σs

∂p

¼0

∂z∗

(5.29)

(5.30)

Examination of Eqs (5.28)–(5.30) shows that the pressure is a function of x*, y* and t*,

p ¼ f x∗ , y∗ , t∗

(5.31)

The continuity equation can be expressed as

σs

∂p∗

∂ ∂ ∂ + Rex

ρ∗ ux∗ + Rey

ρ∗ uy* + Rez

ρ uz* ¼ 0

∂t∗

∂x∗

∂y∗

∂z∗ ∗

(5.32)

Taylor vortices can be formed in a fluid filled annulus with inner cylinder rotation as

illustrated in Figs 5.15 and 5.16. Vortices involve significant acceleration and deceleration of the flow and therefore dissipation of energy and are normally undesirable in

Journal bearings

189

W

a

b

Fig. 5.15 Taylor vortices.

Taylor vortex

Outer cylinder

Inner cylinder

Fig. 5.16 Taylor vortex cells.

any bearing lubrication Scheme. A check can readily be made to identify if Taylor

vortices are likely to occur. If the Taylor number, Tam, based on the mean annulus

radius (Eq. 5.33) is greater than approximately 41.2, then Taylor vortices may

form and laminar flow conditions no longer hold invalidating the use of the equations

developed in this section.

Tam ¼

Ωrm0:5 ðb aÞ1:5

ν

(5.33)

rm ¼ 0:5ðb + aÞ

(5.34)

pffiffiffiffiffiffiffiffiffiffi

Tam,cr ¼ 1697 ¼ 41:19

(5.35)

190

Mechanical Design Engineering Handbook

The critical angular velocity for this case is given by

Ωcr ¼

41:19ν

rm0:5 ðb aÞ1:5

(5.36)

For an annulus with a finite gap,

Ωcr ¼

41:19νFg

rm0:5 ðb aÞ1:5

(5.37)

where Fg is a geometrical factor defined by

π2

b a 1

pffiffiffi 1 Fg ¼

2rm

41:19 S

(5.38)

and S is given in an alternative form by

S ¼ 0:0571 1 0:652

1

ðb aÞ=rm

ðb aÞ=rm

+ 0:00056 1 0:652

1 ðb aÞ=2rm

1 ðb aÞ=2rm

(5.39)

The Froude number (Eq. 5.40) provides an indication of the relative importance of

inertia and gravity forces. A typical Froude number for a journal bearing might be

of the order of 10, providing an indication that gravity forces can be neglected in comparison with viscous forces.

Uo

(5.40)

Fr ¼ pffiffiffiffiffiffi

gL

The importance of pressure relative to inertia can be judged by examination of the

Euler number (Eq. 5.41). For a typical journal bearing the Euler number may be of

the order of 100, giving an indication that the pressure term is much larger than

the inertia term.

Eu ¼

p po

0:5ρUo2

(5.41)

If in addition to neglecting terms of order (ho/lo)2 or (ho/bo)2, terms of the order of ho/lo

and ho/bo are neglected and only terms of the order of unity are considered, the

Navier–Stokes equations reduce to

∂p ∂

∂ux

¼

μ

∂z

∂x ∂z

(5.42)

∂uy

∂p ∂

¼

μ

∂z

∂y ∂z

(5.43)

Journal bearings

191

Eq. (5.31) shows that the pressure is only a function of x and y for steady state conditions. Eqs (5.42), (5.43) can therefore be integrated directly to give general expressions for the velocity gradients as follows.

∂ux z ∂p A

¼

+

∂z μ ∂x μ

(5.44)

∂uy z ∂p C

¼

+

∂z μ ∂y μ

(5.45)

where A and C are constants of integration.

The temperature across the thin layer of layer lubricant in a journal bearing may

vary significantly. As viscosity is highly dependent on temperature, this leads to

increased complexity in obtaining a solution to Eqs 5.44 and 5.45. It has been found

acceptable, however, in many fluid film applications to model the viscosity of a fluid

film using an average value for the viscosity across the film. With μ taken as the average value of viscosity across the fluid film, then integration of Eqs 5.44 and 5.45 gives

the velocity components as follows.

ux ¼

z2 ∂p

z

+A +B

2μ ∂x

μ

(5.46)

uy ¼

z2 ∂p

z

+C +D

2μ ∂y

μ

(5.47)

where B and D are constants of integration.

If the no-slip condition is assumed at the fluid solid interface then the boundary

conditions are as follows and illustrated in Fig. 5.17.

ux ¼ ux, a , uy ¼ uy, a at z ¼ 0

ux ¼ ux, b , uy ¼ uy, b at z ¼ h

Application of the boundary conditions to the equations for the velocity gradients and

velocity components (Eqs 5.46 and 5.47) gives

∂ux 2z h ∂p ux, a ux, b

¼

∂z

h

2μ ∂x

(5.48)

∂uy 2z h ∂p uy, a uy, b

¼

∂z

h

2μ ∂y

(5.49)

ux ¼

zðz hÞ ∂p h z

z

+

ux, a + ux, b

2μ ∂x

h

h

(5.50)

192

Mechanical Design Engineering Handbook

uy, b

uy, a

b

ux, b

ux, a

a

a

b

Fig. 5.17 Journal bearing boundary conditions.

uy ¼

zðz hÞ ∂p h z

z

+

uy, a + uy, b

2μ ∂y

h

h

(5.51)

The viscous shear stresses are defined by

∂uz ∂ux

τzx ¼ μ

+

∂x

∂z

(5.52)

∂uz ∂uy

+

τzy ¼ μ

∂y

∂z

(5.53)

The order of magnitude of ∂ uz/∂ x and ∂ uz/∂ y are much smaller than ∂ ux/∂ z and ∂ uy/∂ z

so the viscous shear stresses can be approximated by

τzx ¼ μ

∂ux

∂z

(5.54)

τzy ¼ μ

∂uy

∂z

(5.55)

From Eqs (5.48), (5.49), the viscous shear stresses acting on the solid surfaces can be

expressed by

∂ux

h ∂p μðux, a ux, b Þ

ðτzx Þz¼0 ¼ μ

¼

∂z z¼0

2 ∂x

h

(5.56)

Journal bearings

193

∂ux

h ∂p μðux, a ux, b Þ

+

ðτzx Þz¼h ¼ μ

¼

∂z z¼h

2 ∂x

h

(5.57)

∂uy

h ∂p μ uy, a uy, b

¼

τzy z¼0 ¼ μ

∂z z¼0

2 ∂y

h

(5.58)

∂uy

h ∂p μ uy, a uy, b

¼

+

τzy z¼h ¼ μ

∂z z¼h

2 ∂y

h

(5.59)

The negative signs for the viscous shear stresses in Eqs (5.56)–(5.59) indicate that the

stress acts in a direction opposite to the motion.

The volumetric flow rates per unit width in the x and y directions are defined by

qx ¼

Z h

ux dz

(5.60)

uy dz

(5.61)

0

qy ¼

Z h

0

Substituting for the velocity components using Eqs (5.50), (5.51) in Eqs (5.60), (5.61)

gives

qx ¼ h3 ∂p ux, a + ux, b

h

+

12μ ∂x

2

(5.62)

qy ¼ h3 ∂p uy, a + uy, b

h

+

12μ ∂y

2

(5.63)

The Reynolds equation is formed by substituting the expressions for the volumetric

flow rate into the continuity equation.

Integrating the continuity equation gives

Z h

0

∂ρ ∂

∂ ∂

+ ðρux Þ +

ρuy + ðρuz Þ dz ¼ 0

∂t ∂x

∂y

∂z

(5.64)

The integral

Z h

∂

∂h ∂

½ f ðx, y, zÞdz ¼ f ðx, y, hÞ +

∂x ∂x

0 ∂x

Z h

f ðx, y, zÞdz

(5.65)

0

If the density is assumed to be the mean density of the fluid across the film, then the ux

term in Eq. (5.64) is

194

Mechanical Design Engineering Handbook

Z h

∂

∂h ∂

ðρux Þdz ¼ ðρux Þz¼h +

ρux dz

∂x ∂x 0

0 ∂x

Z h

∂h ∂

¼ ρux, b +

ρux dz

∂x ∂x 0

Z h

(5.66)

Similarly for the uy term in Eq. (5.64).

Z h

∂ ∂h ∂

ρuy dz ¼ ρuy, b +

∂y ∂y

0 ∂y

Z h

ρuy dz

(5.67)

0

The uz term can be integrated directly giving

Z h

∂

ðρuz Þdz ¼ ρðuz, b uz, a Þ

∂z

0

(5.68)

The integral form of the continuity equation (Eq. 5.64) on substitution of Eqs (5.66)–

(5.68), can be stated as

Z h

∂ρ

∂h ∂

ρ

ux dz

h ρux, b +

∂t

∂x ∂x

Z h0 ∂h ∂

ρuy, b +

ρ

uy dz + ρðuz, b uz, a Þ

∂y ∂y

0

¼0

(5.69)

The integrals in Eq. (5.69) represent the volumetric flow rates per unit width. Substitution of the values for these from Eqs (5.62), (5.63) gives the general Reynolds

equation.

∂

ρh3 ∂p

∂

ρh3 ∂p

∂ ρhðux, a + ux, b Þ

∂ ρh uy, a + uy, b

+

+

+

+

12μ ∂x

12μ ∂y

∂x

∂y

∂x

2

∂y

2

ρðuz, b uz, a Þ ρux, b

∂h

∂h

∂p

ρuy, b + h ¼ 0

∂x

∂y

∂t

(5.70)

The first two terms of Eq. (5.70) are the Poiseuille terms and describe the net flow

rates due to pressure gradients within the lubricated area. The third and fourth terms

are the Couette terms and describe the net entrained flow rates due to surface velocities. The fifth to the seventh terms are due to a squeezing motion. The eighth term

describes the net flow rate due to local expansion as a result of density changes with

time. Eq. (5.70) is repeated below with the identification of the various terms

emphasised.

Journal bearings

195

∂

ρh3 ∂p

∂

ρh3 ∂p

∂ ρhðux, a + ux, b Þ

∂ ρh uy, a + uy, b

+

+

+

12μ ∂x

12μ ∂y

∂x

∂y

∂x

2

∂y

2

|fflfflfflfflfflfflfflfflfflfflfflfflfflfflfflfflfflfflfflfflfflfflfflfflfflfflffl{zfflfflfflfflfflfflfflfflfflfflfflfflfflfflfflfflfflfflfflfflfflfflfflfflfflfflffl} |fflfflfflfflfflfflfflfflfflfflfflfflfflfflfflfflfflfflfflfflfflfflfflfflfflfflfflfflfflfflfflfflfflfflfflffl{zfflfflfflfflfflfflfflfflfflfflfflfflfflfflfflfflfflfflfflfflfflfflfflfflfflfflfflfflfflfflfflfflfflfflfflffl}

Couette

Poiseuille

∂h

∂h

+ρðuz, b uz, a Þ ρux, b ρuy, b +

∂x

∂y

|fflfflfflfflfflfflfflfflfflfflfflfflfflfflfflfflfflfflfflfflfflfflfflfflfflfflfflffl{zfflfflfflfflfflfflfflfflfflfflfflfflfflfflfflfflfflfflfflfflfflfflfflfflfflfflfflffl}

Squeeze

∂p

h

∂t

|{z}

¼0

Net flow due to local expansion

For tangential only motion, where

uz, b ¼ ux, b

∂h

∂h

+ uy, b

∂x

∂y

(5.71)

and uz,a ¼ 0, Eq. (5.70) reduces to

∂ ρh3 ∂p

∂ ρh3 ∂p

∂ðρhÞ

∂ðρhÞ

+

¼ 12ux

+ 12uy

∂x μ ∂x

∂y μ ∂y

∂x

∂y

(5.72)

where

ux ¼

ux, a + ux, b

¼ constant

2

(5.73)

uy ¼

uy, a + uy, b

¼ constant

2

(5.74)

For hydrodynamic lubrication, the fluid properties do not vary significantly through

the bearing and can be considered constant. In addition for hydrodynamic lubrication,

the motion is pure sliding and uy ¼ 0.

The Reynolds equation can therefore be simplified to

∂

∂

∂h

3 ∂p

3 ∂p

h

+

h

¼ 12ux μo

∂x

∂x

∂y

∂y

∂x

(5.75)

In some lubrication applications, side leakage can be neglected and Eq. (5.72) can

be restated as

∂ ρh3 ∂p

∂ðρhÞ

¼ 12ux

∂x μ ∂x

∂x

(5.76)

Eq. (5.76) can be integrated giving

1 dp 12ux

A

¼ 2 + 3

h

μ dx

ρh

(5.77)

196

Mechanical Design Engineering Handbook

With boundary conditions dp/dx ¼ 0 when x ¼ xm, ρ ¼ ρm, h ¼ hm gives

A ¼ 12ux ρm hm . The subscript m refers to the condition for which dp/dx ¼ 0 such

as the point of maximum pressure. Substituting for A in Eq. (5.77) gives

dp

ρh ρm hm

¼ 12ux μ

ρh3

dx

(5.78)

If the density can be considered constant then Eq. (5.78) becomes

dp

h hm

¼ 12ux μ 3

dx

h

(5.79)

For the case of a gas lubricated bearing the density, using the ideal gas law, is given by

ρ¼

p

RT

(5.80)

From Eq. (5.72), and taking the viscosity as constant

∂

∂

∂ðρhÞ

3 ∂p

3 ∂p

ρh

+

ρh

¼ 12ux μo

∂x

∂x

∂y

∂y

∂x

(5.81)

Expressing Eq. (5.72) in cylindrical coordinates

∂ rρh3 ∂p

1 ∂ ρh3 ∂p

∂ðρrhÞ

∂ðρhÞ

+

¼ 12 ur

+ uϕ

μ ∂r

∂r

r ∂ϕ μ ∂ϕ

∂r

∂ϕ

(5.82)

where

ur ¼

ur, a + ur, b

2

(5.83)

uϕ ¼

uϕ, a + uϕ, b

2

(5.84)

If the viscosity and density can be assumed to be constant then Eq. (5.82) becomes

∂

∂p

1 ∂

∂p

∂ðrhÞ

∂h

rh3

+

h3

¼ 12μo ur

+ uϕ

∂r

∂r

r ∂ϕ

∂ϕ

∂r

∂ϕ

(5.85)

Eq. (5.85) applies to a thrust bearing where the fluid film is in the z direction and the

bearing dimensions are in the r, ϕ directions.

For turbulent flow, the Reynolds equation is

∂ h3 ∂p

∂ h3 ∂p

ux ∂h

+

¼

2 ∂x

∂x μkx ∂x

∂y μky ∂y

(5.86)

Journal bearings

197

where (from Constantinescu (1962))

ρΩrh 0:102

kx ¼ 12 + 0:026

μ

(5.87)

ρΩrh 0:091

μ

(5.88)

ky ¼ 12 + 0:0198

For an infinitely wide journal bearing the pressure in the axial direction can

be assumed to be constant. This approach is valid for a length to diameter ratio of

L/D > 2. The integrated form of the Reynolds Equation (Eq. 5.79) on substitution

for ux ¼ ðua + ub Þ=2 ¼ Ωa=2, as ub ¼ 0 for a stationary bearing surface, gives

dp 6μo aΩðh hm Þ

¼

dx

h3

(5.89)

dx ¼ adϕ

(5.90)

dp 6μo a2 Ωðh hm Þ

¼

dϕ

h3

(5.91)

1

cos α ¼ ½h + a + e cos ðπ ϕÞ

b

(5.92)

h ¼ bcos α a + e cos ϕ

(5.93)

Hence, using trigonometric relationships,

0:5

e 2

2

h¼b 1

sin ϕ

a + ecos ϕ

b

(5.94)

Expanding the series

1

e 2

b

0:5

sin 2 ϕ

¼1

1 e 2 2

1 e 4 4

sin ϕ sin ϕ …

2 b

8 b

(5.95)

Hence

1 e 2 2

1 e 4 4

h¼b 1

sin ϕ sin ϕ … a + e cos ϕ

2 b

8 b

(5.96)

ba¼c

(5.97)

h ¼ c + e cos ϕ 1 e

1 e 3 4

sin ϕ …

sin 2 ϕ 2 b

8 b

(5.98)

198

Mechanical Design Engineering Handbook

The ratio e/b is typically of the order of 1 103. As a result terms in Eq. (5.98) with

this ratio can readily be neglected, giving

e

h ¼ c + e cos ϕ ¼ c 1 + cos ϕ ¼ cð1 + ε cos ϕÞ

c

(5.99)

where ε is the eccentricity ratio defined by

ε¼

e

c

(5.100)

Substitution of Eq. (5.99) in Eq. (5.91) gives

"

#

a 2

dp

1

hm

¼ 6μΩ

dϕ

c

ð1 + ε cos ϕÞ2 cð1 + ε cos ϕÞ3

(5.101)

Integration of Eq. (5.101) gives the following expression for the pressure distribution.

a 2 Z

p ¼ 6μΩ

c

"

1

ð1 + εcos ϕÞ2

hm

cð1 + ε cos ϕÞ3

#

dϕ + A

(5.102)

where A is a constant of integration.

For a journal bearing,

x ¼ aϕ

(5.103)

and

u¼

ux, a aΩ

¼

2

2

(5.104)

From Eq. (5.75),

∂

∂h

3 ∂p

2 ∂

3 ∂p

h

+a

h

¼ 6μo Ωa2

∂ϕ

∂ϕ

∂y

∂y

∂ϕ

(5.105)

Substituting for the film thickness gives

∂

∂p

∂2 p

h3

+ a2 h3 2 ¼ 6μo Ωa2 esin ϕ

∂ϕ

∂ϕ

∂y

(5.106)

The Reynolds equation can be solved by approximate mathematical methods or

numerically. Once the pressure distribution has been established the journal performance can be determined in terms of the bearing load capacity, frictional losses, lubricant flow requirements and the lubricant temperature rise.

Journal bearings

5.4.2

199

Design charts for full-film hydrodynamic bearings

If the designer wishes to avoid the direct solution of Eq. (5.3), use can be made of a

series of design charts. These were originally produced by Raimondi and Boyd

(1958a, b, c) who used an iterative technique to solve the Reynolds equations. These

charts give the film thickness, coefficient of friction, lubricant flow, lubricant side

flow ratio, minimum film thickness location, maximum pressure ratio, maximum

pressure ratio position and film termination angle versus the Sommerfield number

(Figs 5.18–5.25).

The Sommerfield number, which is also known as the bearing characteristic number, is defined in Eq. (5.107). It is used as it encapsulates all the parameters usually

defined by the designer. Great care needs to be taken with units in the design of journal

bearings. Many design charts have been produced using English units (psi, reyn, Btu

etc.). As long as a consistent set of units is maintained, use of the charts will yield

sensible results. In particular note the use of revolutions per second in the definition

of speed in the Sommerfield number.

S¼

r 2 μN

c

s

P

(5.107)

where:

S is the bearing characteristic number;

r is the journal radius, (m);

c is the radial clearance (m);

μ is the absolute viscosity (Pa s);

Ns is the journal speed (revolutions per second, rps);

P ¼ W/LD is the load per unit of projected bearing area (N/m2);

W is the load on the bearing (N);

D is the journal diameter (m);

L is the journal bearing length (m).

Consider the journal shown in Fig. 5.26. As the journal rotates it will pump lubricant in

a clockwise direction. The lubricant is pumped into a wedge-shaped space and the

journal is forced over to the opposite side. The angular position where the lubricant

film is at its minimum thickness ho is called the attitude angle, ϕ. The centre of the

journal is displaced from the centre of the bearing by a distance e called the eccentricity. The ratio of the eccentricity e to the radial clearance c is called the eccentricity

ratio (ε ¼ e/c). The relationship between the film thickness, the clearance, eccentricity

and eccentricity ratio are defined in Eqs (5.108)–(5.110).

ho ¼ c e

(5.108)

e

c

(5.109)

h0

¼1ε

c

(5.110)

ε¼

200

1

0.9

L/D = inf

Minimum film

thickness variable ho / c

0.8

0.7

0.6

L/D = 1

L/D = 0.5

L/D = 0.25

Max W

0.5

Min f

0.4

0.3

0.1

0

0.001

0.01

0.1

1

2

Sommerfield number, S = (a/c) µNs /P

Fig. 5.18 Chart for the minimum film thickness variable, (ho/c) versus the Sommerfield number.

Data from Raimondi and Boyd (1958c).

10

Mechanical Design Engineering Handbook

0.2

Journal bearings

Coefficient of friction variable, (r/c)f

1000

100

10

1

0.1

0.001

L/D = inf

L/D = 1

L/D = 0.5

L/D = 0.25

0.01

0.1

1

10

Sommerfield number, S = (r/c) mNs /P

2

201

Fig. 5.19 Chart for determining the coefficient of friction variable, (r/c)f.

Data from Raimondi, A.A., Boyd, J., 1958c. A solution for the finite journal bearing and its application to analysis and design: III. ASLE

Trans. 1, 194–209.

202

7

Flow variable, Q/rcNsL

6

5

4

3

2

1

0

0.001

0.01

0.1

1

10

100

Sommerfield number, S = (r/c) mNs /P

2

Fig. 5.20 Chart for determining the flow variable, Q/(acNsL).

Data from Raimondi, A.A., Boyd, J., 1958c. A solution for the finite journal bearing and its application to analysis and design: III. ASLE Trans. 1,

194–209.

Mechanical Design Engineering Handbook

L/D = inf

L/D = 1

L/D = 0.5

L/D = 0.25

Journal bearings

1.2

Flow ratio Qs/Q

1

0.8

0.6

0.4

0.2

0

0.001

L/D = 1

L/D = 0.5

L/D = 0.25

0.01

0.1

1

10

Sommerfield number, S = (r/c) mNs /P

2

203

Fig. 5.21 Chart for determining the ratio of side flow, Qs, to total flow, Q.

Data from Raimondi, A.A., Boyd, J., 1958c. A solution for the finite journal bearing and its application to analysis and design: III. ASLE

Trans. 1, 194–209.

Position of minimum film thickness f(degree)

100

90

80

70

60

50

40

30

L/D = inf

L/D = 1

L/D = 0.5

L/D = 0.25

20

10

0

0.001

0.01

0.1

1

10

Sommerfield number, S = (r/c)2mNs /P

Fig. 5.22 Chart for determining the position of the minimum film thickness ϕ.

Data from Raimondi, A.A., Boyd, J., 1958c. A solution for the finite journal bearing and its

application to analysis and design: III. ASLE Trans. 1, 194–209.

0.9

Maximum film pressure ratio P/Pmax

0.8

L/D = inf

L/D = 1

L/D = 0.5

L/D = 0.25

0.7

0.6

0.5

0.4

0.3

0.2

0.1

0

0.001

0.01

0.1

1

10

Sommerfield number, S = (r/c)2mNs /P

Fig. 5.23 Chart for determining the maximum film pressure ratio, p/pmax.

Data from Raimondi, A.A., Boyd, J., 1958c. A solution for the finite journal bearing and its

application to analysis and design: III. ASLE Trans. 1, 194–209.

Location of maximum film pressure (degree)

25

L/D = inf

L/D = 1

L/D = 0.5

L/D = 0.25

20

15

10

5

0

0.001

0.01

0.1

1

10

Sommerfield number, S = (r/c)2mNs /P

Fig. 5.24 Chart for determining the position of maximum pressure, φpmax.

Data from Raimondi, A.A., Boyd, J., 1958c. A solution for the finite journal bearing and its

application to analysis and design: III. ASLE Trans. 1, 194–209.

160

Terminating position of film (degree)

140

120

100

80

60

40

L/D = inf

L/D = 1

L/D = 0.5

L/D = 0.25

20

0

0.001

0.01

0.1

1

10

Sommerfield number, S = (r/c)2mNs /P

Fig. 5.25 Chart for determining the film termination angle, φpo.

Data from Raimondi, A.A., Boyd, J., 1958c. A solution for the finite journal bearing and its

application to analysis and design: III. ASLE Trans. 1, 194–209.

206

Mechanical Design Engineering Handbook

Start

Speeding up

Steady speed

e

ho

Journal

Bearing

Centre line

shift

Centre line

shift

Fig. 5.26 Full film hydrodynamic bearing motion from start up.

One of the assumptions made in the analysis of Raimondi and Boyd is that the viscosity of the lubricant is constant as it passes through the bearing. However, work is done

on the lubricant in the bearing and the temperature of the lubricant leaving the bearing

zone will be higher than the entrance value. Fig. 5.7 shows the variation of viscosity

with temperature for some of the SAE and ISO defined lubricants and it can be seen

the value of the viscosity for a particular lubricant is highly dependent on the temperature. Some of the lubricant entrained into the bearing film emerges as side flow which

carries away some of the heat. The remainder flows through the load-bearing zone and

carries away the remainder of the heat generated. The temperature used for determining the viscosity can be taken as the average of the inlet and exit lubricant temperatures as given by Eq. (5.111).

Tav ¼ T1 +

T2 T1

ΔT

¼ T1 +

2

2

(5.111)

where T1 is the temperature of the lubricant supply and T2 is the temperature of the

lubricant leaving the bearing. Generally petroleum lubrication oils should be limited

to a maximum temperature of approximately 70°C to prevent excessive oxidation.

One of the parameters that needs to be determined is the bearing lubricant exit temperature T2. This is a trial and error or iterative process. A value of the temperature

rise, ΔT, is guessed, the viscosity for a standard oil, corresponding to this value, determined and the analysis performed. If the temperature rise calculated by the analysis

does not correspond closely to the guessed value the process should be repeated using

an updated value for the temperature rise until the two match. If the temperature rise is

unacceptable it may be necessary to try a different lubricant or modify the bearing

configuration.

Given the length, the journal radius, the radial clearance, the lubricant type and its

supply temperature the steps for determining the various bearing operating parameters

are given in Table 5.4.

The temperature rise of the lubricant through the bearing can be determined from

Journal bearings

207

Table 5.4 Full-film hydrodynamic bearing design guideline

Start Selection

Determine speed and load

Determine the speed of the journal and the

load to be supported.

No

OK

Determine bearing L and D

No

OK

Determine the radial clearance, c

No

OK

Select a lubricant

No

OK

If L and D not already determined, set the

proportions of the bearing so that the load

capacity, P = W/LD, is somewhere

between 0.34 MN/m2 for light machinery to

13.4 MN/m2 for heavy machinery

Determine a value for the radial clearance,

c, of the bearing using the data presented

in Figure 5.14.

If not already specified select a lubricant.

Lubricant oil selection is a function of speed

or compatibility with other lubricant

requirements. Generally as the design

speed rises, oils with a lower viscosity

should be selected.

Estimate a value for the temperature rise

DT across the bearing. The value taken for

Estimate DT

No

OK

Calculate Tav

No

OK

Calculate the Sommerfield number

Determine

the

average

lubricant

temperature Tav=T1+ DT/2 and find the

corresponding value for the viscosity for the

chosen lubricant.

Calculate the Sommerfield number, S =

(r/c)2 µNs/P and the length to diameter ratio.

No

OK

Determine (r/c)f, Q/(rcNsL), (Qs/Q)

2

the initial estimate is relatively

unimportant. As a guide, a value of DT = 10

°C is generally a good starting guess. This

value can be increased for high speed

bearings and for low bearing clearances

No

OK

Use the charts (Figs. 5.19, 5.20 and 5.21)

to determine values for the coefficient of

friction variable, the total lubricant flow

variable, and the ratio of the side flow to the

total lubricant flow with the values for the

Sommerfield number and the L/D ratio.

1

Continued

208

Mechanical Design Engineering Handbook

Table 5.4 Continued

1

2

Calculate T

Calculate the temperature rise of the

lubricant through the bearing using

T

OK

Does T match previous value

No

OK

Check operation in optimal zone

OK

Calculate Q, Qs, f

OK

Calculate ho,p/pmax,fpmax,fpo

OK

Calculate the torque

OK

Calculate the power lost

OK

Specify surface roughness

OK

Design lubricant system

OK

Complete

8.30 10 6 P

r /c f

1 21 Qs / Q Q / rcNsL

If the calculated value does not match the

estimated value for T to within say 1°C

repeat the procedure from the calculation

of Tav using the updated value of the

temperature rise to determine the average

lubricant temperature.

Check the values for S and L/D ratio give a

design that is in the optimal operating

region for minimal friction and maximum

load capability on the chart for the minimum

film thickness variable (Fig. 5.18). If the

operating Sommerfield number and L/D

ratio combination do not fall within this zone,

then it is likely that the bearing design can

be improved by altering values for c, L, D,

the lubricant and the operating temperature.

If the temperature rise across the bearing

has converged, calculate values for the

total lubricant flow rate, Q, the side flow rate

Qs and the coefficient of friction f.

Figs. 5.18 to 5.25 can be used to determine

values for the maximum film thickness, the

maximum film pressure ratio, the location

of the maximum film pressure and its

terminating angular location as required.

The torque required to overcome friction in

the bearing can be calculated by

Torque = fWr

The power lost in the bearing is given by

Power = w Torque = 2pNs Torque

Specify the surface roughness for the

journal and bearing surfaces. A ground

journal with an arithmetic average surface

roughness of 0.4 to 0.8

m is

recommended for bearings of good quality.

For high precision equipment surfaces can

be lapped or polished to give a surface

roughness of 0.2 to 0.4 m. The specified

roughness should be less than the

minimum film thickness.

Design the recirculation and

system for the bearing lubricant.

sealing

Journal bearings

ΔT ¼

209

8:30 106 P

ðr=cÞf

1

Q=rcN s L

1 ðQs =QÞ

2

(5.112)

The torque required to overcome friction in the bearing can be calculated by

Torque ¼ fWr

(5.113)

The power lost in the bearing is given by

Power ¼ ω Torque ¼ 2πNs Torque

(5.114)

where ω is the angular velocity (rad/s).

For values of the length to diameter (L/D) ratio other than those shown in the charts

given in Figs 5.18–5.25, values for the various parameters can be found by interpolation using Eq. (5.115)(Raimondi and Boyd, 1958b).

3

1

L

L

L

1

1

2

1

4

y

+

∞

7

1 6

D D

6 8

7

D

y¼

5

34 1

L

L

1

L

L

1

L

L

ðL=DÞ

12

14

y1 1 14

y1=2 +

1

12

y1=4

3

D

D

4

D

D

24

D

D

2

(5.115)

Here y is the desired variable and y∞, y1, y1/2 and y1/4 are the variable at L/D ¼ ∞, 1,

1/2 and 1/4 respectively.

Ø50

Ø50.08

Example 5.3. A full journal bearing has a nominal diameter of 50.0 mm and a bearing

length of 25.0 mm (Fig. 5.27). The bearing supports a load of 3000 N, and the journal

design speed is 3000 rpm. The radial clearance has been specified as 0.04 mm. An SAE

10 oil has been chosen and the lubricant supply temperature is 50°C.

Find the temperature rise of the lubricant, the lubricant flow rate, the minimum film

thickness, the torque required to overcome friction and the heat generated in the

bearing.

3000 N

25.0

Fig. 5.27 Bearing design example.

210

Mechanical Design Engineering Handbook

Solution

The primary data are D ¼ 50.0 mm, L ¼ 25 mm, W ¼ 3000 N, N ¼ 3000 rpm,

c ¼ 0.04 mm, SAE 10, T1 ¼ 50°C.

Guess a value for the lubricant temperature rise ΔT across the bearing to be say

ΔT ¼ 20°C.

Tav ¼ T1 +

ΔT

20

¼ 50 + ¼ 60° C

2

2

From Fig. 5.7 for SAE 10 at 60°C, μ ¼ 0.014 Pa s.

The mean radius is given by

rm ¼

a + b 25 + 25:04

¼

¼ 25:02 mm

2

2

b a ¼ 0:04mm

Assuming a density of 900 kg/m3,

ν ¼ μ=ρ ¼ 0:014=900 ¼ 1:55 105 m2 =s

So the Taylor number using this approximate value for the kinematic viscosity is

given by

Tam ¼

Ωrm0:5 ðb aÞ1:5

¼ 0:81

ν

As this is much less than the critical Taylor number, 41.19, laminar flow can be

assumed.

Ns ¼ 3000=60 ¼ 50rps, L=D ¼ 25=50 ¼ 0:5:

P¼

S¼

W

3000

¼

¼ 2:4 106 N=m2

LD 0:025 0:05

r 2 μN

c

25 103

¼

P

0:04 103

s

2

0:014 50

¼ 0:1139

2:4 106

From Fig. 5.19 with S ¼ 0.1139 and L/D ¼ 0.5, (r/c)f ¼ 3.8.

From Fig. 5.20 with S ¼ 0.1139 and L/D ¼ 0.5, Q/(rcNsL) ¼ 5.34.

From Fig. 5.21 with S ¼ 0.1139 and L/D ¼ 0.5, Qs/Q ¼ 0.852.

The value of the temperature rise of the lubricant can now be calculated using

Eq. (5.112):

r

f

8:3 106 P

8:3 106 2:4 106 3:8

c

¼ 24:70° C

¼

ΔT ¼

Qs

Q

1 ð0:5 0:852Þ

5:34

1 0:5

Q

rcN s L

Journal bearings

211

As the value calculated for the lubricant temperature rise is significantly different to

the estimated value, it is necessary to repeat the above calculation but using the new

improved estimate for determining the average lubricant temperature.

°

Using ΔT ¼ 24.70°C to calculate Tav gives: Tav ¼ 50 + 24:70

2 ¼ 62:35 C.

Repeating the procedure using the new value for Tav gives:

μ ¼ 0:0136Pas,

S ¼ 0:1107,

from Fig. 5.19 with S ¼ 0.1107 and L/D ¼ 0.5, (r/c)f ¼ 3.7,

from Fig. 5.20 with S ¼ 0.1107 and L/D ¼ 0.5, Q/(rcNsL) ¼ 5.35,

from Fig. 5.21 with S ¼ 0.1107 and L/D ¼ 0.5,Qs/Q ¼ 0.856,

ΔT ¼

8:3 106 2:4 106 3:7

¼ 24:08° C,

1 ð0:5 0:856Þ

5:35

Tav ¼ 50 +

24:08

¼ 62:04° C:

2

This value for Tav is close to the previous calculated value suggesting that the solution

has converged. For Tav ¼ 62.04°C, μ ¼ 0.0136 Pa s and S ¼ 0.1107.

The other parameters can now be found.

Q ¼ rcN s L 5:35 ¼ 25 0:04 50 25 5:35 ¼ 6688mm3 =s:

From Fig. 5.18ho/c ¼ 0.22. ho ¼ 0.0088 mm.

f ¼ 3:7 ðc=r Þ ¼ 3:7 ð0:04=25Þ ¼ 0:00592:

The torque is given by Torque ¼ fWr ¼ 0.00592 3000 0.025 ¼ 0.444 N m.

The

power

dissipated

in

the

bearing

is

given

Power ¼ 2π Torque Ns ¼ 139.5 W.

by

Example 5.4. A full journal bearing is required for a 30 mm diameter shaft, rotating

at 1200 rpm supporting a load of 1500 N (Fig. 5.28). From previous experience, the