HW6 Stephen Huse 1.

advertisement

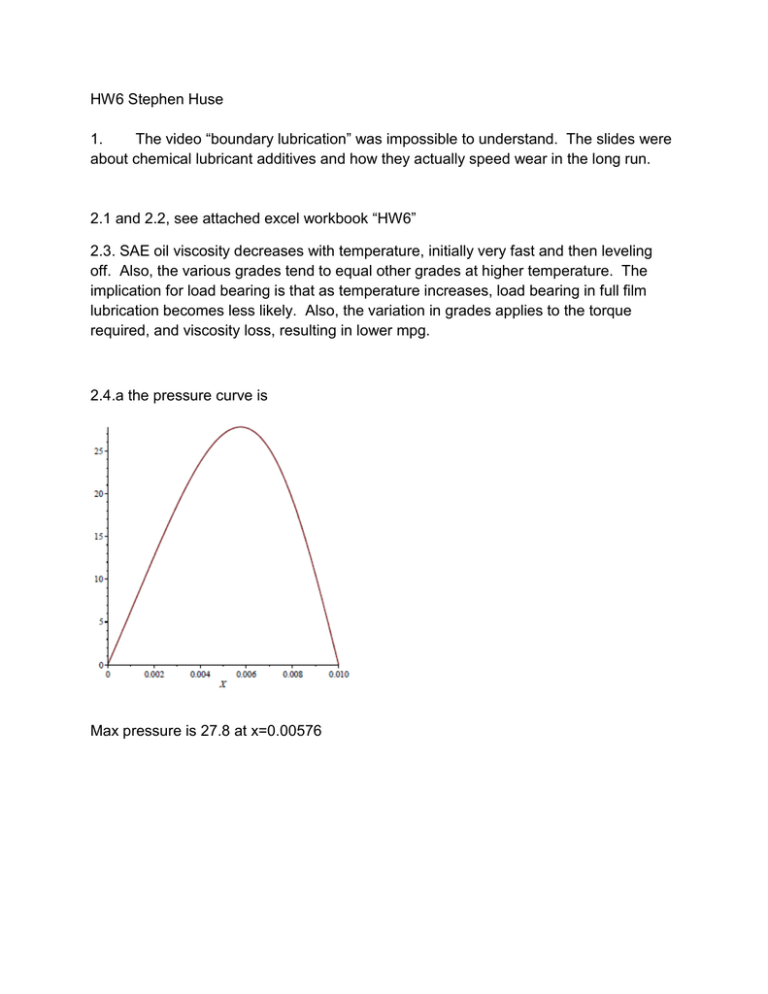

HW6 Stephen Huse 1. The video “boundary lubrication” was impossible to understand. The slides were about chemical lubricant additives and how they actually speed wear in the long run. 2.1 and 2.2, see attached excel workbook “HW6” 2.3. SAE oil viscosity decreases with temperature, initially very fast and then leveling off. Also, the various grades tend to equal other grades at higher temperature. The implication for load bearing is that as temperature increases, load bearing in full film lubrication becomes less likely. Also, the variation in grades applies to the torque required, and viscosity loss, resulting in lower mpg. 2.4.a the pressure curve is Max pressure is 27.8 at x=0.00576 2.4b the pressure curve for the linear bearing is max pressure is 25 at x=0.00667. The cylinder has more pressure and at an earlier location than the tilted pad bearing. 2.5 See the comsol report for details. Note: viscosity in the in-class model was 1e-2 Pa.s which is not what the question had which was 0.1 Pa.s 3. See the report in the project directory for the latest draft.