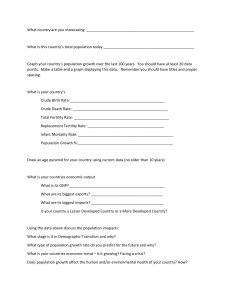

doi:10.1515/auoc-2016-0011 Ovidius University Annals of Chemistry Volume 27, Number 1, pp. 62-72, 2016 Estimation of pressure drop in gasket plate heat exchangers Anisoara Arleziana NEAGU1, Claudia Irina KONCSAG1,*, Alina BARBULESCU2 and Elisabeta BOTEZ3 Department of Chemistry and Chemical Engineering, “Ovidius” University of Constanta, 124 Mamaia Street, 900521 Constanta, Romania 2 Higher Colleges of Technology, Sharjah, UAE 3 Department of Food Science, Food Engineering and Applied Biotechnology, ”Dunarea de Jos” University, 111 Domneasca Street, 800201 Galati, Romania 1 Abstract. In this paper, we present comparatively different methods of pressure drop calculation in the gasket plate heat exchangers (PHEs), using correlations recommended in literature on industrial data collected from a vegetable oil refinery. The goal of this study was to compare the results obtained with these correlations, in order to choose one or two for practical purpose of pumping power calculations. We concluded that pressure drop values calculated with Mulley relationship and Buonopane & Troupe correlation were close and also Bond’s equation gave results pretty close to these but the pressure drop is slightly underestimated. Kumar correlation gave results far from all the others and its application will lead to oversize. In conclusion, for further calculations we will chose either the Mulley relationship or the Buonopane & Troupe correlation. Keywords: pressure drop, edible oils, gasket plate heat exchangers. 1. Introduction In order to be placed on the market, vegetable oils are subject to a refining process, when the product is improving both in terms of sensorial quality and stability during shelf storage. Gasket plate heat exchangers (PHE) are customary in all modern vegetable oil refineries. The Chevron type gasket plate heat exchangers were introduced in 1930 with dedication to the food industry because they have very good transfer coefficients and can be easily cleaned [1-4]. The calculation of pressure drop is an important part of the technological dimensioning of gasket plate heat exchangers since the power consumption for pumping is determined by the pressure loss in the equipment. The estimation of pressure drop in exchangers is made with different correlations recommended in literature. All these correlations take into account the geometry of the equipment, the hydrodynamic regime and the physical properties of fluids. Due to the regular shape of cross-corrugated passages in the PHEs, numerical models can reproduce with fidelity the geometry when investigating the buoyancy effects on pressure losses [5]. In recent years, the authors use finite element computational fluid dynamics (CFD) for the analysis of tortuosity, shape factor and friction factor determination [6]. * Also, the Re-Normalization Group (RNG) method is used for the re-normalization of NavierStokes equations in prediction of vortex evolution and the calculation of friction factors and pressure losses [7]. However, different simple correlations developed empirically in laboratory by Kumar, Mulley, Bond, Buonopane, Gulenoglu and other scientists [8-13] can be applied in industrial conditions. The aim of this work was to select a reliable mathematical model from these simple correlations, for the estimation of pressure drop in gasket plate heat exchangers used in the vegetable oil refining industry. 2. Theoretical approach The chevron-type plate is the most used element for PHEs. The plate corrugations are in form of chevron because this pattern is easy to manufacture. Longitudinal and transversal corrugations are plotted in two separated plans [7] and the corrugation angle can be 30o, 45o or 60o, but most frequently 60o. In Fig. 1, the chevron- type plate is presented with the principal dimensions, some of them being used in hydrodynamic calculations: Lp- vertical portto-port channel length, m; Leff- effective length, m; Lh- horizontal port-to-port channel length, m; Lwwidth of flow channel, m; Dp- port diameter, m; βchevron angle, deg. Corresponding author: ckoncsag@univ-ovidius.ro © 2016 Ovidius University Press Unauthenticated Download Date | 6/30/16 9:28 AM A. A. Neagu et al. / Ovidius University Annals of Chemistry 27 (2016) 62-72 The mass velocity for the cold and hot fluids in the port is calculated by Eq. (4): �̇ �� = (4) � where ̇ represents the total flow rate in the port opening (kg/s), Dp – the port diameter, m [6, 8, 9]. As one can see in Eq.1-4, the pressure drop in heat exchangers depends on equipment geometry, physical properties of fluids and flow conditions. The friction factor, f, is of great importance and there are dedicated correlations for its estimation. For example, Kumar correlations (5) and (6) correlate f with the flow regime expressed as Reynolds numbers [13, 14]: = Fig.1.Chevron-type plate = +∆ � ∆�� = ∙ (1) where ∆ � represents the total pressure drop (Pa), ∆ – channel pressure drop (Pa), ∆ � – port pressure drop (Pa). The channel pressure drop is defined by the Eq. (2): ∙ � ∙� ℎ ∙( ��ℎ ∙ �,ℎ )∙ � � − . (2) where f represents the friction factor, nondimensional; Lp –vertical port-to-port channel length, m; Np – number of passes; dh –hydraulic diameter, m; Gch – the fluid mass velocity in the channel, kg∙m-2∙s; ρc,h – density for the cold respectively for the hot fluid, kg/m3; μ – dynamic viscosity of fluid at the mean temperature in the apparatus, Pa∙s; μw – dynamic viscosity of fluids at the wall temperature, Pa∙s. The friction factor f is calculated with different equations from literature as function of Reynolds number and chevron angle. The pressure drop in the port ducts can be estimated with Eq. (3) [13]: ∆ � = . ∙ �� ∙ ( � ∙ �,ℎ ) , for � = , � − , for � > , 8 (5) (6) It is important to know that, according to Kumar’s observations, the critical Reynolds value for the transition from the laminar to the turbulent flow in PHEs, is approximately 100 [6,14] since for other authors [15,16] , the turbulent regime starts at Re≅ 400. The early buoyancy apparition is linked to the shape of cross-corrugated passages and the abrupt change in density and viscosity of fluids due to strong variation of its temperature in a short distance. Other researchers developed correlations of f with Re, in their own way, following experimental studies. All these equations (Eq. 5-10) are empirical: - Bond correlation I [13]: The total pressure drop is the sum of pressure drop in channels and in the ports. It can be estimated with the Eq. (1): ∆ �=∆ ͷͿ,ͺͶͶ � Ͷ,ͻ;Ϳ = ∙ � − , , (7) - Buonopane & Troupe correlation [11]: = , � (8) , - Bond correlation II [9]: ∙� − , = , (9) - Gulenoglu correlation [12]: = , ∙� − , + , (10) Mulley [12] developed a more complex correlation (Eq. 11) taking into account the most important geometrical dimension, from the viewpoint of friction, the corrugation inclination angle relative to vertical direction, β, so called chevron angle: (3) where Np represents the number of passes, Gp –mass velocity of fluid in the port, kg∙m-2 ∙s; ρc,h – density for cold / hot fluids, kg/m3. = � , 63 Unauthenticated Download Date | 6/30/16 9:28 AM ∙[ � , + � , , ] , (11) A. A. Neagu et al. / Ovidius University Annals of Chemistry 27 (2016) 62-72 of ±0,005 oC for temperature, ±0,0002 g/cm3 for density and ±0,1% for the viscosity. The variation curves of density and viscosity with temperature were draw and discussed in previous works [17, 18]. Properties for cooling water and steam were found in [19]. With the geometrical characteristics of each heat exchanger and the physical properties of fluid calculated in the working conditions, the pressure drop was calculated for each circuit with the following correlations: Kumar (Eq. 5 or 6 depending on flow regime), Bond I (Eq. 7), Buonopane & Troupe (Eq. 8), Bond II (Eq. 9), Gulenoglu (Eq. 10) and Mulley (Eq. 11). Results are presented in Tables 1-6, each table corresponding to one of the six PHEs in the industrial plant. 3. Experimental There were six gasket plate heat exchangers in the industrial plant of different size and with different working fluids (oils with changing properties, cooling water and condensing steam). In the degumming and neutralization stage, the working fluids are crude oil - bleached oil in PHE #1, crude oil – steam in PHE #2, crude oil – water in PHE #3 and crude oil – steam in PHE #4. In the winterizing stage, the working fluids are bleached oil – water in PHE #5 and in the deodorization stage the working fluids are deodorization oil – water in PHE #6. The experiment was performed in three campaigns, as follows: - Campaign 1: processing sunflower oil - Campaign 2: processing rapeseed oil - Campaign 3: processing sunflower oil Every campaign was a few days long, the stock of raw had constant quality during one campaign and the flow rates and temperatures in the process were constant for days. However, inside of each campaign, there were found little changes in flow rates and temperatures, allowing us to have in the end 9 different sets of data for the purposes of this study. The physical properties of oils (density, viscosity), in all stages of the process, were measured at atmospheric pressure with Anton Parr SVM 3000 apparatus, following the ASTM D445/ISO 121852 method, in the range of 20 oC-110 oC, with a precision 4. Results and Discussions For gasket plate heat exchanger PHE #1, the working fluids are crude oil - bleached oil. Both fluids are liquid and work in the laminar flow (Re<100). The pressure drop values calculated for this equipment with Eq. 5-11 are presented in Table 1. It can be observed that the highest values of pressure drop are obtained using Kumar relationship Eq. 5, 23 times higher than using other methods. Mulley and Buonopane & Troupe correlations give closer results, as also seen in Table 7. Table 1. Pressure drop in PHE #1 calculated with different correlations Working fluids Density, [kg/m3] Dinamic viscosity, [Pa·s] Flow rate, [kg/s] Reynolds number Crude oil 890.0 0.0132 1.736 27 Bleached oil 877.6 0.0131 2.138 58 Crude oil 890.0 0.0132 2.049 32 Bleached oil 877.6 0.0131 2.524 68 Crude oil 890.0 0.0132 2.457 39 Bleached oil 877.6 0.0131 3.026 81 Crude oil 890.0 0.0132 2.713 43 Bleached oil 877.6 0.0131 3.342 90 Pressure drop, [Pa] Kumar correlation Mulley correlation Bond I correlation Buonopane & Troupe correlation 17765 4 17769 19046 6 19052 15884 5 15,889 24255 8 24263 14173 8 14181 31655 12 31667 13358 9 13367 36763 14 36778 8876 4 8880 1096 6 10702 8227 5 8,232 13698 8 13706 7571 8 7579 19660 12 19672 7236 9 7245 21252 14 21266 12396 4 12400 16734 6 16740 16440 5 16,445 22149 8 22157 22376 8 22384 30122 12 30134 26485 9 26494 35770 14 35784 First campaing, sunflower oil ∆ ∆ � ∆ � ∆ ∆ � ∆ � ∆ ∆ � ∆ � ∆ ∆ � ∆ � ∆ ∆ � ∆ � ∆ ∆ � ∆ � ∆ ∆ � ∆ � ∆ ∆ � ∆ � 36957 4 36961 40217 6 40223 46732 5 46,737 50819 8 50827 60339 8 60347 65548 12 65560 69399 9 69409 75508 14 75522 64 Unauthenticated Download Date | 6/30/16 9:28 AM A. A. Neagu et al. / Ovidius University Annals of Chemistry 27 (2016) 62-72 Second campaign, rapeseed oil Crude oil 876.0 0.0162 2.72 45 Bleached oil 888.80 0.0126 3.35 72 Crude oil 889.9 0.0142 1.736 33 Bleached oil 877.1 0.011 2.138 53 Crude oil 889.9 0.0142 2.049 39 Bleached oil 877.1 0.011 2.524 62 Crude oil 889.9 0.0142 2.457 47 Bleached oil 877.1 0.011 3.026 75 Crude oil 889.9 0.0142 2.713 52 Bleached oil 877.1 0.011 3.342 82 ∆ ∆ � ∆ � ∆ ∆ � ∆ � 68356 9 68365 83279 14 83293 32150 9 32159 39870 14 39884 17558 9 17567 22691 14 22705 26562 9 26571 36823 14 36837 15837 4 15841 19587 6 19593 19893 5 19898 24921 8 24929 25706 8 25713 32537 12 32549 29633 9 29642 37668 14 37682 8243 4 8247 10870 6 10876 10646 5 10651 14038 8 14046 14088 8 14096 18578 12 18590 16416 9 16426 21648 14 21662 11864 4 11868 16827 6 16833 15726 5 15731 22304 8 22312 21414 8 21422 30371 12 30383 25344 9 25353 35945 14 35959 Third campaign, sunflower oil ∆ ∆ � ∆ � ∆ ∆ � ∆ � ∆ ∆ � ∆ � ∆ ∆ � ∆ � ∆ ∆ � ∆ � ∆ ∆ � ∆ � ∆ ∆ � ∆ � ∆ ∆ � ∆ � The working fluids for gasket plate heat exchanger PHE #2 are crude oil and steam. The results of pressure drop for crude oil – steam are presented in Table 2. Reynolds numbers indicate a turbulent flow either we accept the critical Re>100 [6, 14], or Re>400 [15, 16] for the transition to the turbulent flow. As a consequences, pressure drop on the oil circuit are higher than those in the PDE #1. It can be observed from Table 2 that the Kumar relationship give the highest values of pressure drops 33464 4 33468 41509 6 41515 42283 5 42288 5244 8 52455 54631 8 54639 67764 12 67776 62832 9 62841 77935 14 77494 for both oil and steam circuits. The pressure drop on the condensing steam circuit is higher than on oil because the turbulent flow is well developed. By comparing the values of pressure drop in the steam circuit, there are observed high differences, the Kumar correlation giving results tenfold higher than Bond correlation and even differences between the other correlations’ results are important. This is due to the fact that all these correlations were produced for liquids working in PHEs. Table 2. Pressure drop values in PHE #2 calculated with different correlations Working fluids Density, [kg/m3] Dinamic viscosity, [Pa·s] Flow rate, [kg/s] Crude oil 874.3 0.0087 1.736 Steam 1.923 0.000015 0.023 Crude oil 874.3 0.0087 2.049 Steam 1.923 0.000015 0.028 Pressure drop, [Pa] Reynolds number Kumar correlation Mulley correlation Buonopane & Troupe correlation Bond I correlation 39621 3 39624 14136 6 14142 46261 5 46266 18135 8 24339 3 24342 35002 6 35008 31488 5 31493 46396 8 11830 3 11833 10037 6 10042 15999 5 16004 12962 8 First campaign, sunflower oil ∆ ∆ � ∆ � ∆ ∆ � ∆ � ∆ ∆ � ∆ � ∆ ∆ � 328 9309 387 10987 50223 3 50227 121950 6 121956 66606 5 666611 164814 8 65 Unauthenticated Download Date | 6/30/16 9:28 AM A. A. Neagu et al. / Ovidius University Annals of Chemistry 27 (2016) 62-72 Crude oil 874.3 0.0087 2.475 Steam 1.923 0.000015 0.033 Crude oil 874.3 0.0087 2.713 Steam 1.923 0.000015 0.037 Crude oil 873.0 0.011 2.72 Steam 1.923 0.000015 0.037 Crude oil 873.2 0.0091 1.736 Steam 1.923 0.000015 0.028 Crude oil 873.2 0.0091 2.049 Steam 1.923 0.000015 0.033 Crude oil 873.2 0.0091 2.475 Steam 1.923 0.000015 0.033 Crude oil 873.2 0.0091 2.713 Steam 1.923 0.000015 0.037 ∆ � ∆ ∆ � ∆ � ∆ ∆ � ∆ � ∆ ∆ � ∆ � ∆ ∆ � ∆ � 467 13175 513 14548 164822 91885 7 91892 229239 11 229250 107664 8 107671 274474 14 274488 18143 50814 7 50821 23802 11 23813 77655 8 77663 27618 14 27632 46396 42167 7 42174 63175 11 63186 48709 8 48717 74769 14 74783 12970 22536 7 22542 17155 11 17156 26734 8 26743 19989 14 20003 93262 36 93270 27819 15 27834 57976 36 57985 74992 15 75007 18531 36 18567 20105 15 20120 43562 4 43562 14136 6 14142 56631 5 56636 18135 8 18143 74357 7 74363 23802 11 23813 86273 8 86281 27618 14 27632 26925 4 26929 35002 6 35008 34991 5 34996 46396 8 46396 46307 7 46314 63175 11 63186 53959 8 53968 74769 14 74783 22612 4 22616 10037 6 10042 28251 5 28256 12962 8 12970 39294 7 39301 17155 11 17156 47047 8 47052 19989 14 20003 Second campaign, rapeseed oil ∆ ∆ � ∆ � ∆ ∆ � ∆ � 425 14585 18583 36 18619 274625 15 274640 Third campaign, sunflower oil ∆ ∆ � ∆ � ∆ ∆ � ∆ � ∆ ∆ � ∆ � ∆ ∆ � ∆ � ∆ ∆ � ∆ � ∆ ∆ � ∆ � ∆ ∆ � ∆ � ∆ ∆ � ∆ � 313 9309 369 10987 443 13175 489 14548 Working fluids for gasket plate heat exchanger PHE#3 are crude oil and water. Table 3 presents the values of pressure drops. From Table 3, also it can be observed that highest values of pressure drop are obtained with Kumar correlation. Also, there are higher values of pressure drop on water circuit because the mass velocity of water is three times higher than that of oil in similar flow sections; it is to be considered that pressure drop 58810 4 58814 121950 6 121956 73513 5 73518 164814 8 164822 100100 7 100107 229239 11 229250 118470 8 118478 274474 14 274488 is also dependent on friction factor, f, decreasing with Re, and f is four times higher in the oil circuit. The combined effect of this two antagonist factors led to pressure drop double in the water circuit. For gasket plate heat exchanger PHE #4, the working fluids are crude oil and steam. The pressure drop values for this equipment are presented in Table 4. 66 Unauthenticated Download Date | 6/30/16 9:28 AM A. A. Neagu et al. / Ovidius University Annals of Chemistry 27 (2016) 62-72 Table 3. Pressure drop values in PHE #3 calculated with different correlations Working fluids Density, [kg/m3] Dinamic viscosity, [Pa·s] Flow rate, [kg/s] Crude oil 888.0 0.0157 1.736 Water 987.9 0.00077 5.251 Crude oil 888.0 0.0157 2.049 Water 987.9 0.00077 6.198 Crude oil 888.0 0.0157 2.475 Water 987.9 0.00077 7.432 Crude oil 888.0 0.0157 2.713 Water 987.9 0.00077 8.206 Crude oil 886.7 0.0152 2.720 Water 987.9 0.00077 8.227 Crude oil 886.9 0.0132 1.736 Water 987.9 0.00077 5.251 Crude oil 886.9 0.0132 2.049 Water 987.9 0.00077 6.198 Crude oil 886.9 0.0132 2.475 Water 987.9 0.00077 7.432 Crude oil 886.9 0.0132 2.713 Water 987.9 0.00077 8.206 Pressure drop, [Pa] Reynolds number Kumar correlation Mulley correlation Bond I correlation Buonopane & Troupe correlation 11185 2 11187 6978 15 6993 14570 3 14572 8134 21 8156 19634 4 19638 11397 31 11428 23182 5 23186 13701 38 13740 3212 2 3214 5135 15 5150 4149 3 4152 6616 21 6637 5491 4 5495 9272 31 9303 6402 5 6407 15126 38 15164 4415 2 4417 9203 15 9218 5852 3 5855 11766 21 11788 7969 4 7973 16211 31 16242 9437 5 9441 19266 38 19304 22824 5 22829 13769 38 13807 6211 5 6215 11194 38 11232 9201 5 9205 19352 38 19390 11439 2 11441 6942 16 6958 15586 3 15589 7230 22 7252 17751 4 17755 11285 31 11316 20794 5 20799 13584 38 13622 2915 2 2917 5017 16 5033 3765 3 3788 6747 22 6769 4984 4 4988 9334 31 9365 5842 5 5847 1143 38 11181 4116 2 4118 9018 16 9034 5457 3 5460 11955 22 11977 7430 4 7434 16279 31 16310 8794 5 8799 19267 38 19305 First campaign, sunflower oil ∆ ∆ � ∆ � ∆ ∆ � ∆ � ∆ ∆ � ∆ � ∆ ∆ � ∆ � ∆ ∆ � ∆ � ∆ ∆ � ∆ � ∆ ∆ � ∆ � ∆ ∆ � ∆ � 25 154 29 1782 35 2155 39 2386 13563 2 13565 26009 15 26024 17136 3 17139 33701 21 33723 22142 4 22146 47596 31 47627 25476 5 25480 57321 38 57359 Second campaign, rapeseed oil ∆ ∆ � ∆ � ∆ ∆ � ∆ � 40 2391 24608 5 24612 57511 38 57549 Third campaign, sunflower oil ∆ ∆ � ∆ � ∆ ∆ � ∆ � ∆ ∆ � ∆ � ∆ ∆ � ∆ � ∆ ∆ � ∆ � ∆ ∆ � ∆ � ∆ ∆ � ∆ � ∆ ∆ � ∆ � 29 1526 35 1801 42 2160 46 2385 12034 2 12036 25433 16 25449 15207 3 15210 34372 22 34394 19648 4 19651 47808 31 47839 22597 5 22602 5724 38 57280 67 Unauthenticated Download Date | 6/30/16 9:28 AM A. A. Neagu et al. / Ovidius University Annals of Chemistry 27 (2016) 62-72 Table 4. Pressure drop values in PHE #4 calculated with different correlations Working fluids Density, [kg/m3] Dinamic viscosity, [Pa·s] Flow rate, [kg/s] Crude oil 883.4 0.0128 1.736 Steam 1.923 0.000015 0.050 Crude oil 883.4 0.0128 2.049 Steam 1.923 0.000015 0.059 Crude oil 883.4 0.0128 2.475 Steam 1.923 0.000015 0.071 Crude oil 883.4 0.0128 2.713 Steam 1.923 0.000015 0.078 Crude oil 882.1 0.0133 2.72 Steam 1.923 0.000015 0.078 Crude oil 882.3 0.0115 1.736 Steam 1.923 0.000015 0.050 Crude oil 882.3 0.0115 2.049 Steam 1.923 0.000015 0.059 Crude oil 882.3 0.0115 2.457 Steam 1.923 0.000015 0.071 Crude oil 882.3 0.0115 2.713 Steam 1.923 0.000015 0.078 Pressure drop, [Pa] Reynolds number Kumar correlation First campaign, sunflower oil 102 33443 ∆ 14 ∆ � 33457 ∆ � 9104 89006 ∆ 73 ∆ � 89079 ∆ � 120 45131 ∆ 19 ∆ � 45150 ∆ � 10745 120291 ∆ 101 ∆ � 120392 ∆ � 144 63085 ∆ 28 ∆ � 63113 ∆ � 12885 167311 ∆ 145 ∆ � 167456 ∆ � 159 75320 ∆ 35 ∆ � 75355 ∆ � 14228 200326 ∆ 177 ∆ � 200503 ∆ � Second campaign, rapeseed oil 154 83473 ∆ 35 ∆ � 83508 ∆ � 14265 209422 ∆ 1851 ∆ � 209607 ∆ � Third campaign, sunflower oil 113.4 35936 ∆ 14 ∆ � 35950 ∆ � 9104 89006 ∆ 73 ∆ � 89079 ∆ � 134 48566 ∆ 20 ∆ � 48586 ∆ � 10745 120291 ∆ 101 ∆ � 120392 ∆ � 161 67551 ∆ 28 ∆ � 67579 ∆ � 12885 167311 ∆ 145 ∆ � 167456 ∆ � 177 80881 ∆ 35 ∆ � 80816 ∆ � 14228 200326 ∆ 177 ∆ � 200503 ∆ � The pressure drop in the crude oil circuit in PHE #4 is smaller than in similar PHE #2 because the route length is smaller and the section area is double in PHE #4 comparing with PHE#2. The same can be said about pressure drop on steam circuit. Also, the same Mulley correlation Bond I correlation Buonopane & Troupe correlation 16312 14 16326 10390 73 10443 20840 19 20859 13323 101 13424 27440 28 27468 17495 145 17640 31778 35 31813 20299 177 20476 9495 14 9519 7370 73 7443 12230 19 12249 9519 101 9620 16242 28 16270 12597 145 12742 18912 35 18947 14678 177 14855 16278 14 16292 25613 73 25686 21532 19 21551 33950 101 34051 29499 28 29527 46230 145 46375 34792 35 34827 54714 177 54891 35650 35 35685 20450 185 20635 21180 35 21215 14820 185 15005 38780 35 38816 55012 185 55197 16906 14 16910 10390 73 10443 21652 20 21672 13323 101 13424 28406 28 28434 17495 145 17640 32948 35 32983 20299 177 20476 9894 14 9908 7370 73 7443 12778 20 12798 9519 101 9620 16911 28 16939 12597 145 12742 19705 35 19740 14678 177 14855 17273 14 17287 25613 73 25686 22896 20 22916 33950 101 34051 31177 28 31205 46230 145 46375 36899 35 36934 54714 177 54891 considerations made at PHE #2 about the differences between the results calculated with different correlations for the steam circuit are valid for the PHE#4. 68 Unauthenticated Download Date | 6/30/16 9:28 AM A. A. Neagu et al. / Ovidius University Annals of Chemistry 27 (2016) 62-72 Table 5. Pressure drop values in PHE #5 calculated with different correlations Working fluids Density, [kg/m3] Dinamic viscosity, [Pa·s] Flow rate, [kg/s] Bleached oil 895.2 0.022 1.940 Water 988.4 0.00078 2.546 Bleached oil 895.2 0.022 2.193 Water 988.4 0.00078 2.878 Bleached oil 895.2 0.022 2.490 Water 988.4 0.00078 3.268 Bleached oil 895.2 0.022 2.755 Water 988.4 0.00078 3.616 Bleached oil 893.6 0.018 2.76 Water 988.4 0.00078 3.622 Bleached oil 894.65 0.0206 1.940 Water 988.4 0.00078 2.546 Bleached oil 894.65 0.0206 2.193 Water 988.4 0.00078 2.878 Bleached oil 894.65 0.0206 2.490 Water 988.4 0.00078 3.268 Bleached oil 894.65 0.0206 2.755 Water 988.4 0.00078 3.616 Pressure drop, [Pa] Reynolds number Kumar correlation Bond I correlation Buonopane & Troupe correlation Muley correlation 6321 2 6323 2240 4 2244 7653 3 7656 2778 5 2783 9314 4 9318 3480 6 3486 10838 5 10843 4163 7 4170 8713 2 8715 4207 4 4211 10718 3 10721 5144 5 5149 13315 4 13319 6384 6 6390 15808 5 15813 7594 7 7601 13034 2 13036 2556 4 2560 15268 3 15330 3287 5 3292 18071 4 18075 4065 6 4158 20734 5 20737 4905 7 4912 10525 5 10530 4173 7 4180 15455 5 15460 7603 7 7610 19781 5 19786 4930 7 4937 5739 2 5741 2223 4 2227 6935 3 6937 2768 5 2773 8432 4 8436 3474 6 3480 9854 5 9859 4162 7 4169 8141 2 8143 4178 4 4182 10027 3 10030 5146 5 5151 12442 4 12446 6386 6 6392 14776 5 14781 7584 7 7591 11227 2 11229 2556 4 2560 13243 3 13246 3210 5 3215 15776 4 15780 4065 6 4071 18181 5 18186 4905 7 4912 First campaign, sunflower oil ∆ ∆ � ∆ � ∆ ∆ � ∆ � ∆ ∆ � ∆ � ∆ ∆ � ∆ � ∆ ∆ � ∆ � ∆ ∆ � ∆ � ∆ ∆ � ∆ � ∆ ∆ � ∆ � 25 921 28 1038 32 1179 35 1305 26727 2 26729 11165 4 11169 31757 3 31760 13977 5 13982 37996 4 38000 17487 6 17493 41614 5 41619 21054 7 21061 Second campaign, rapeseed oil ∆ ∆ � ∆ � ∆ ∆ � ∆ � 38 1306 42012 5 42017 21069 7 21076 Third campaign, sunflower oil ∆ ∆ � ∆ � ∆ ∆ � ∆ � ∆ ∆ � ∆ � ∆ ∆ � ∆ � ∆ ∆ � ∆ � ∆ ∆ � ∆ � ∆ ∆ � ∆ � ∆ ∆ � ∆ � 30 919 34 1038 39 1179 43 1304 The working fluids for gasket plate heat exchanger #5 are bleached oil and water. The 23577 2 23579 11102 4 11106 28029 3 28032 13872 5 13877 33529 4 33533 17473 6 17479 38672 5 38677 21003 7 21010 calculated pressure drop values for bleached oil and water are presented in Table 5. 69 Unauthenticated Download Date | 6/30/16 9:28 AM A. A. Neagu et al. / Ovidius University Annals of Chemistry 27 (2016) 62-72 In this case too, the pressure drops calculated by Kumar relationship are higher than with other methods. The methods of Bond, Mulley and Buonopane give closer values. In the heat exchanger #6 the working fluids are deodorized oil – water. The pressure drop values for this equipment are presented in Table 6. Table 6. Pressure drop values in PHE #6 calculated with different correlations Working fluids Density, [kg/m3] Dinamic viscosity, [Pa·s] Flow rate, [kg/s] Pressure drop, [Pa] Reynolds number Kumar correlation Bond I correlation Buonopane & Troupe correlation Mulley correlation 1123 2 1125 2099 24 2124 1449 3 1451 2827 28 2855 1920 4 1924 3706 41 3747 2234 5 2239 4656 50 4706 1484 2 1486 3937 24 3962 1963 3 1966 5205 28 5234 2678 4 2682 7046 41 7087 3171 5 3176 8375 50 8425 2500 2 2502 2437 24 2457 3059 3 3062 3316 28 3345 3854 4 3858 4646 41 4688 4389 5 4394 5584 50 5634 2268 5 2273 4708 50 4758 3167 5 3172 8458 50 8509 4543 5 4547 5612 50 5663 1117 2 1119 2113 20 2133 1442 3 1445 2841 29 2870 1909 4 1913 3930 41 3972 2224 5 2229 4691 50 4741 1461 2 1463 3947 20 3968 1936 3 1939 5233 29 5261 2637 4 2641 7125 41 7166 3120 5 3125 8430 50 8481 2540 2 2542 2440 20 2460 3098· 3 3101 3320 29 3349 3890 4 3894 4652 41 4693 4422 5 4426 5590 50 5641 First campaign, sunflower oil Deodorized oil 879.2 0.0109 1.736 Water 986.75 0.00074 6.02 Deodorized oil 879.2 0.0109 2.049 Water 986.75 0.00074 7.100 Deodorized oil 879.2 0.0109 2.475 Water 986.75 0.00074 8.500 Deodorized oil 879.2 0.0109 2.713 Water 986.75 0.00074 9.400 Deodorized oil 878.7 0.012 2.720 Water 986.75 0.00074 9.436 Deodorized oil 879.2 0.0116 1.736 Water 986.75 0.00074 6.022 Deodorized oil 879.2 0.0116 2.049 Water 986.75 0.00074 7.108 Deodorized oil 879.2 0.0116 2.457 Water 986.75 0.00074 8.523 Deodorized oil 879.2 0.0116 2.713 Water 986.75 0.00074 9.410 ∆ ∆ � ∆ � ∆ ∆ � ∆ � ∆ ∆ � ∆ � ∆ ∆ � ∆ � ∆ ∆ � ∆ � ∆ ∆ � ∆ � ∆ ∆ � ∆ � ∆ ∆ � ∆ � 19 979 23 1154 27 1379 30 1528 4904 2 4906 10533 24 10558 6137 3 6140 14186 28 14215 8003 4 8007 19611 41 19652 9205 5 9210 23614 50 23664 Second campaign, rapeseed oil ∆ ∆ � ∆ � ∆ ∆ � ∆ � 27 1533 9449 5 9454 23868 50 23919 Third campaign, sunflower oil ∆ ∆ � ∆ � ∆ ∆ � ∆ � ∆ ∆ � ∆ � ∆ ∆ � ∆ � ∆ ∆ � ∆ � ∆ ∆ � ∆ � ∆ ∆ � ∆ � ∆ ∆ � ∆ � 18 979 21 1156 26 1386 28 1530 4915 2 4917 10568 20 10589 6210 3 6213 14283 29 14312 8024 4 8028 19867 41 19908 9226 5 9231 23635 50 23685 70 Unauthenticated Download Date | 6/30/16 9:28 AM A. A. Neagu et al. / Ovidius University Annals of Chemistry 27 (2016) 62-72 Following this comparative study we recommend the relationships of Mulley and Buonopane & Troupe for the estimation of pressure drop in gasket plate heat exchangers. The Kumar correlation should be applied with caution since it results in oversizing. These correlations wouldn’t be considered for the calculation of pressure drop on condensing steam circuits since they weren’t worked out for this type of fluid. In the PHE #6, the pressure drop calculated with Kumar correlation is higher than after the use of other methods, and all the other considerations for PHE# 3 and #5 (oil-water) are valid for PHE#6. To compare all the pressure drop values obtained by applying different methods, the results of calculations with Buonopane & Troupe correlation were taken as a reference and relative errors to this were calculated. The relative error is calculated with Eq. 12: � ���� �� � = ∆� − ∆��� ∆��� � � � � × References [%] (12) [1] C.S. Fernandes, R.P. Dias, J.M. Maia, Recent Patents on Mechanical Engineering 1 (3), 198205 (2008) [2] A.H.K. Al-Tae, Comparative study of temperature control in a heat exchanger process. M. Sc. Thesis, Chemical Engineering/Unit Operation, University of Technology (2011) [3] D.H. Han, K.J. Lee and Y.H. Kim, Journal of the Korean Physical Society 43 (1), 66-73, (2003) [4] G.N. Jogi and M.S. Lawankar, International Journal of Emerging Technology and Advanced Engineering 2 (10), 110-115 (2012) [5] I. Gherasim, M. Taws, N. Galanis and C.T. Nguyen, Applied Thermal Engineering 51, 346363 (2013) [6] C.S. Fernandes, R.P. Dias, J.M. Noberga and J.M. Maia, Chemical Engineering and Processing 46, 825-833 (2007) [7] Z.Luan, G. Zhang, M. Tian and M. Fan, Journal of Hydrodynamics 20(4), 524-529 (2008) [8] G. Gulenoglu, F. Akturk, S. Aradag, N.S. Uzol, S. Kakac, International Journal of Thermal Sciences 75, 249-256, (2014) [9] V.R. Naik, V.K. Matawala, International Journal of Engineering and Advanced Technology (IJEAT), 2 (4), 362-369 (2013) [10] T. Kuppan, Heat Exchanger Design Handbook, Hemisphere Publishing Corporation, New York, (2000) [11] S. Kakac, H. Liu, Heat Exchangers. Selection, Rating and Thermal Design, Second Edition, CRC Press (2002) [12] F. Akturk, G. Gulben, S. Aradag, , N.S. Uzol, S. Kakac, 6th International Advanced Technologies Symposion, 16-18 May,172-178 ( 2011) [13] S. Kakac, H. Liu, Heat Exchangers Selection, Rating, and Thermal and Design, second ed., CRC Press, Boca Raton, 373–412 (2002) [14] H. Kumar, The plate heat exchanger: construction and design, in: Proceedings First, UK National Conference on Heat Transfer, University of Leeds, Inst. Chem. Symp. Series No. 86, 1275–1288, (1984), cited in [6] The comparison was made only for liquid as a working fluid, because the original correlations were worked out on experimental data on liquids. Results are presented in Table 7: Table 7. Average relative errors of pressure drop values calculated with different methods compared with those obtained with Buonopane & Troupe method, %. PHE # 1 2 3 4 5 6 Kumar method +136.5 +114.0 +183.8 +171.63 +176.32 +191.01 Mulley method - 2.0 -36.4 -29.4 -9.0 +16.3 +11.7 Bond I method -41.7 -37.7 -35.9 -35.7 -38.2 -36.1 The pressure drop values calculated with Mulley relationship and Buonopane & Troupe correlation were close and also Bond’s equation gave results close to the previous but systematically underestimated. Kumar correlation gave results far from all the others and its application will lead to oversize. Following this comparative study we recommend the relationships of Mulley and that of Buonopane to be used for the estimation of pressure drop in gasket plate heat exchangers. The Kumar correlation should be applied with caution since it results in oversizing. 5. Conclusions Different models developed by Kumar, Mulley, Bond and Buonopane & Troupe were applied in industrial conditions on six PHEs in an industrial plant, in different size and working with different fluids (oils with changing properties, cooling water and condensing steam). The pressure drop values calculated with Mulley relationship and Buonopane correlation were very close and also Bond’s equation gave results close to the previous but slightly underestimated. Kumar correlation gave results far from all the others and its application will lead to oversize. 71 Unauthenticated Download Date | 6/30/16 9:28 AM A. A. Neagu et al. / Ovidius University Annals of Chemistry 27 (2016) 62-72 [18] A.A Neagu, I. Niţă, E. Botez, S. Geacai, Ovidius University Annals of Chemistry 24 (2), 121-126 (2013) [19] K. Raznjevic, Thermodynamic Tables and Diagrams (Tabele si diagrame termodinamice, in Romanian), Ed. Tehnica, Bucharest (1978) [15] W.W. Focke, J. Zachariades, I. Olivier, The effect of the corrugation inclination angle on the thermo-hydraulic performance of plate heat exchangers, International Journal of Heat and Mass Transfer 28 (8), 1469-1479 (1985) [16] A. Cooper, J.D. Usher, Heat Exchanger Design Handbook, Vol. 3, Section 3.7. Plate heat exchangers, Hemisphere, Washington, USA (1983) [17] A.A. Neagu, I. Niţă, E. Botez, Ovidius University Annals of Chemistry 25 (2), 71–74 (2014) Received: 10.04.2016 Received in revised form: 08.06.2016 Accepted: 09.06.2016 72 Unauthenticated Download Date | 6/30/16 9:28 AM